1

11

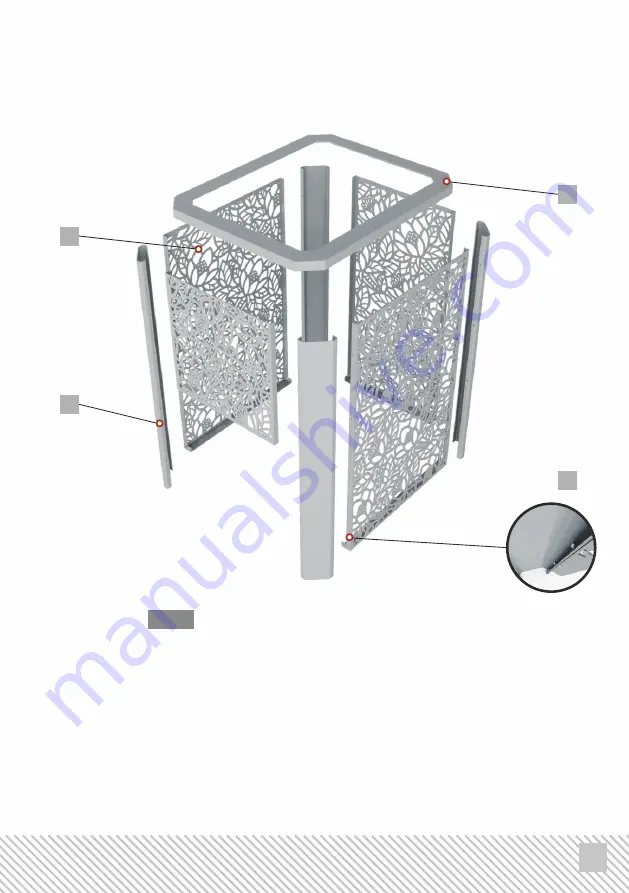

Side walls of the protective cover (point 1) are attached to legs (point 1) with screws (point 3).

Put the assembled protective cover on the furnace (the cut-out notch should be placed on the flue

chimney side). The clearances between the wall of the furnace and protective cover are filled in with

stones (this makes up an outer heater). Then put boards (point 5) on the top. Lay stones on the top of

the furnace.

ASSEMBLY SCHEME FOR THE

PROTECTIVE COVER

Pic

. 4

Assembly scheme for the protective cover

1

2

4

3

Summary of Contents for YALTA

Page 1: ...YALTA INSTALLATION AND MAINTENANCE ...

Page 10: ...1 10 Pic 3 The passage for the combustion flue ...

Page 26: ...26 ...

Page 27: ......

Page 28: ......