QUICK START GUIDE

10

|

P a g e

5. INTRODUCTION OF STARTING UP THE PRINTER

5.1

Power On

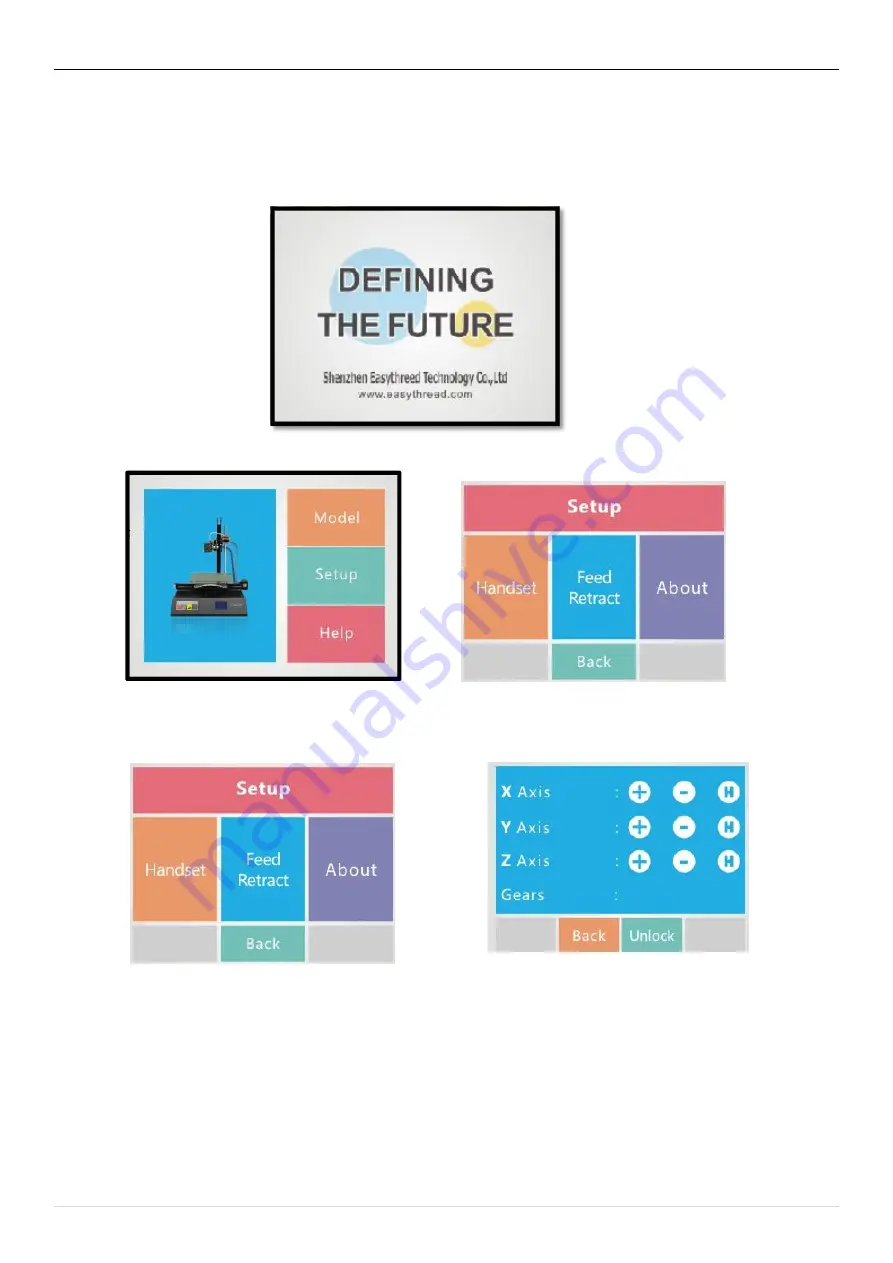

Plug the power cord->Insert SD card->Power Switch on. The 3d printer starts up, as follows,

Touch LCD Display, goes to operation page, click setup, it comes the following.

Click handset, goes to XYZ adjustment operation page, click back after operation completed.

Click Feed/Retract, goes to Filament operation page,

operate per instruction, click back after operation

completed.

Put filament to the hose, Once reach to the preset temperature, then click Feed, filament comes out from nozzle,

means feed successfully. Put filament to the hose, once reach to the preset temperature, then click retract, filament comes

out form the hose, means retract successfully.