3

5HP INLINE PUMP MANUAL REV030921

Personal Protective Equipment

Be sure all

Be sure all operators and others around the pump and its controls comply with all applicable OSHA,

Federal, State and Local regulations, codes, and standards relating to personal protective equipment. This includes

respiratory protective equipment, protection for the extremities, protective clothing, protective shields and barriers,

electrical protective equipment, and personal hearing protective equipment.

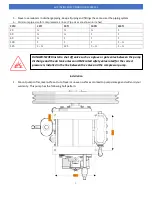

Warning: Be sure to install belt guard after pump installation. Failure to do so can lead to serious injury.

Area

1.

Install compressor pump in a clean, dry, and well-lit area. Be sure installation area can maintain a temperature

range between 35 degrees Fahrenheit (1.6 degrees Celsius) and 110 degrees Fahrenheit (43.3 degrees Celsius).

2.

Insulate cold water or other low temperature pipes that pass overhead to avoid condensation dripping on pump

which could cause rust or moisture build up.

3.

If acid is used in operating environment or air is dust laden, you

MUST

pipe intake air from outside. Increase

pipe by one size for every 20 feet of run length. Be sure to install a protective hood around intake filter(s).

4.

Allow sufficient space around pump for maintenance access. Mount with pulley towards wall and leave a

minimum of 15 inches of clearance.

5.

Ensure location where pump is mounted is level. Uneven locations can damage the pump and void pump

warranty.

Piping

1.

Install appropriate flow-limiting valves as necessary according to pipe size and run length. This will reduce

pressure in case of hose failure per OSHA Standard 29 CFR 1926.302(b)(7).

2.

Flow-limiting valves are listed by pipe size and rated CFM. Select appropriate valves accordingly in accordance

with manufacturers recommendations.

3.

Air systems should be checked daily for leaks. This helps to prevent unnecessary load/wear on the pump.

4.

Ensure any tube, pipe, fitting, or hose connected to the pump can withstand operating temperatures and retain

pressure.

Read all manuals and information supplied for this unit carefully. Be thoroughly

familiar with all inspection and operation guidelines. Only persons that have

read and understand this manual should operate this pump.

DANGER: DO N

OT install pump in boiler room, paint spray room, or area where

sandblasting occurs. Make sure inlet air is away from exhaust fumes or other toxic,

noxious, or corrosive fumes or substances.

WARNING: Never use plastic (PVC) pipe for compressed air. Serious injury or death

could result. Piping MUST have a pressure rating of 200 PSI or greater.

Summary of Contents for 5HP

Page 1: ...APP2I0524TP 5HP INLINE PUMP MANUAL REV030921...

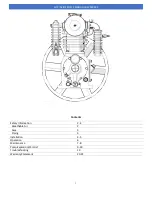

Page 10: ...9 5HP INLINE PUMP MANUAL REV030921 Pump Explosion Parts List...

Page 11: ...10 5HP INLINE PUMP MANUAL REV030921...

Page 12: ...11 5HP INLINE PUMP MANUAL REV030921...

Page 13: ...12 5HP INLINE PUMP MANUAL REV030921...

Page 14: ...13 5HP INLINE PUMP MANUAL REV030921...

Page 15: ...14 5HP INLINE PUMP MANUAL REV030921...

Page 16: ...15 5HP INLINE PUMP MANUAL REV030921...

Page 17: ...16 5HP INLINE PUMP MANUAL REV030921...

Page 18: ...17 5HP INLINE PUMP MANUAL REV030921...