5

5HP INLINE PUMP MANUAL REV030921

2.

Connect main feed line to check valve. Pump

MUST

have a check valve installed inline to tank. This helps to

prevent the pump from starting underload. This also prevents air loss and premature pump wear. Minimum line

ID size for main line

is 5/8”. This can

be flexible or solid.

DO NOT

install the unit with a shut off valve anywhere

in the main feed line. This could lead to serious injury or death.

Output threads are ¾” FNPT.

3.

Pressure lubed pumps

DO NOT

have built in unloaders and require a separate relief valve. This will relieve head

pressure once the pump stops and provide no-load restarting.

4.

Cylinder heads are equipped with continuous run lines. If the lines are not to be used, please cap input side.

Lines on the head are for input from a manufacturer approved pilot valve only.

DO NOT

run lines from relief

valve or unregulated lines from the tank to this system.

5.

Use proper pulley for motor size and RPM.

DO NOT

exceed pump maximum recommended RPM. Exceeding

pump RPM will cause premature wear/damage to the pump and will void pump warranty.

6.

Pulley calculation worksheet:

Pump

Flywheel OD Pump RPM

min

Pump RPM

max

Motor RPM

Suggested Size*

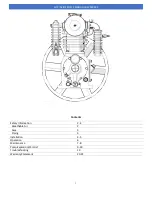

APP2I0543TP

16.75

450

800

Per Application

Flywheel

x

Pump RPM

/

Motor RPM

=

Pulley OD

*EXAMPLE: 16.75

” x 8

00 (pump RPM) / 1750 (example) motor RPM = suggested pulley size of 7.7

”

7.

This model

of pump requires the use of two, ‘B’ groove belts.

8.

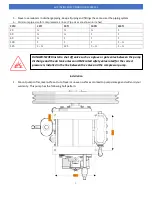

Rotation of the pump should be clockwise when facing the pressure gauge, or counterclockwise from the

flywheel side.

9.

Use care when aligning pump flywheel and motor pulley. Ensure center ridge on pump and pulley are in line.

Any direction out of line will cause premature belt wear.

10.

When tightening belts check for belt deflection. Deflection should be no more than ½ inch.

Input lines for continuous run set up only.

DO

NOT

run lines from other sources to these

locations. Use only a manufacturer approved

pilot valve for continuous run use.

Proper belt tension is determined by pressing midway between the

motor pulley and the pump flywheel.

Summary of Contents for 5HP

Page 1: ...APP2I0524TP 5HP INLINE PUMP MANUAL REV030921...

Page 10: ...9 5HP INLINE PUMP MANUAL REV030921 Pump Explosion Parts List...

Page 11: ...10 5HP INLINE PUMP MANUAL REV030921...

Page 12: ...11 5HP INLINE PUMP MANUAL REV030921...

Page 13: ...12 5HP INLINE PUMP MANUAL REV030921...

Page 14: ...13 5HP INLINE PUMP MANUAL REV030921...

Page 15: ...14 5HP INLINE PUMP MANUAL REV030921...

Page 16: ...15 5HP INLINE PUMP MANUAL REV030921...

Page 17: ...16 5HP INLINE PUMP MANUAL REV030921...

Page 18: ...17 5HP INLINE PUMP MANUAL REV030921...