6

5HP INLINE PUMP MANUAL REV030921

Operation

1.

The unit is shipped with pump break-in oil and should be ready to operate. Be sure to check for proper oil level

before running. Break in oil should be change after 100 Hours of operation (active pumping time). See

maintenance section for more information on oil changes and frequency.

2.

Oil pressure on startup will vary due to ambient temperatures but should not exceed 100 PSI. Once the unit is

allowed to run a few cycles and come to optimal operating temperature, oil pressure should stabilize at 20-35

PSI. If the oil pressure remains high or drops too low, it can be adjusted as follows:

3.

This pump is designed to operate with 1.85 Pints, or roughly 1 quart of oil.

4.

It is strongly advised to use only Airbase Industries piston compressor oil. Check with your warranty/extended

warranty guidelines to verify oil selection and use. Oil used in the pump must fall under the following criteria:

synthetic, SAE grade 30, non-detergent, piston compressor oil. Failure to use the correct oil will void your

warranty.

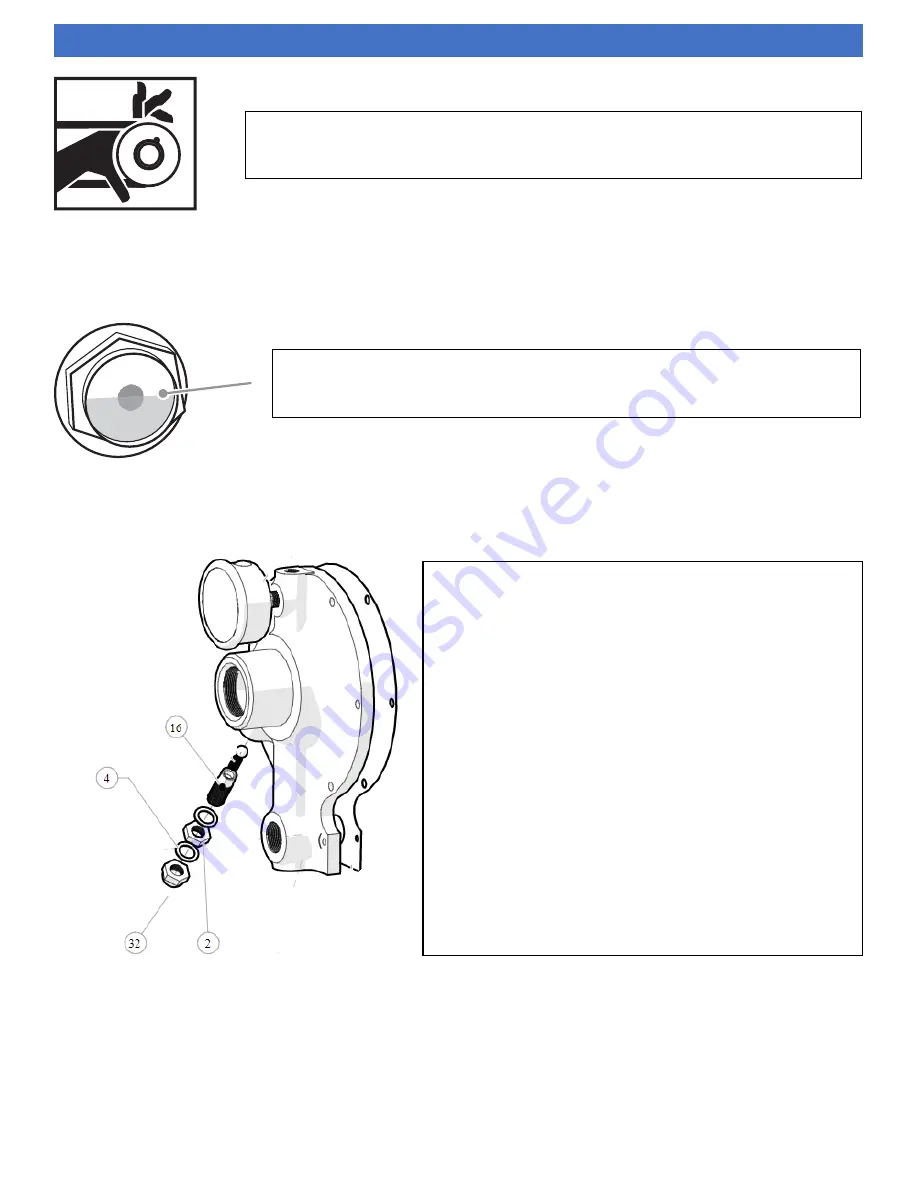

Oil level should be to the center of the red circle in the sight glass. Oil level WILL

drop once the unit turns on and oil begins to circulate.

When facing the oil pressure gauge. Look to the 7 o’clock

position. You will see an acorn nut (#32). Remove the acorn

nut and be careful to not lose the rubber seal (#4) sitting

behind it. Loosen but do not remove the set nut (#2). You will

see a flat head screwdriver slot in the end of the adjustor

(#16). To increase pressure, turn the adjustor clockwise; to

decrease pressure turn then adjustor counterclockwise. Turn

no more than ½ turn at a time. Then allow the unit to cycle to

measure the adjustment.

TAKE CARE

when lowering pressure not to back the adjustor

out completely.

Once oil pressure is set, hold the adjustor (#16) in position

and retighten set nut (#2). Replace rubber seal (#4) and

reinstall acorn nut (#32).

FAILURE

to reinstall acorn nut, seals, or set nuts can result in

oil leaks.

WARNING: Always make sure main power is off prior to touching belts or other

moving parts of the pump.

Summary of Contents for 5HP

Page 1: ...APP2I0524TP 5HP INLINE PUMP MANUAL REV030921...

Page 10: ...9 5HP INLINE PUMP MANUAL REV030921 Pump Explosion Parts List...

Page 11: ...10 5HP INLINE PUMP MANUAL REV030921...

Page 12: ...11 5HP INLINE PUMP MANUAL REV030921...

Page 13: ...12 5HP INLINE PUMP MANUAL REV030921...

Page 14: ...13 5HP INLINE PUMP MANUAL REV030921...

Page 15: ...14 5HP INLINE PUMP MANUAL REV030921...

Page 16: ...15 5HP INLINE PUMP MANUAL REV030921...

Page 17: ...16 5HP INLINE PUMP MANUAL REV030921...

Page 18: ...17 5HP INLINE PUMP MANUAL REV030921...