7

5HP INLINE PUMP MANUAL REV030921

Maintenance

1.

Make sure repairs and service are done in a clean, dry, well-lit, and well-ventilated area.

2.

When cleaning/blowing off,

DO NOT

exceed 30 PSI (2.1 bar) of pressure.

NEVER

use solvents for cleaning

purposes. Also use effective chip guarding and personal protective equipment per OSHA Standard 29 CFR

190.242(b).

3.

Relieve all internal pressure prior to opening any line, fitting, hose, valve, drain plug, connection or any other

such component before refilling airline anti-icer systems with antifreeze compound.

4.

Maintenance Schedule.

Item

Frequency

Comment

Cleanliness

Daily

Keep the pump and the surrounding area clean. Wipe off oil, spills, and

dirt/dust.

Oil Level

Daily

Check oil level while the power is

OFF.

If oil is low add to fill point. If

level is high, drain off oil.

Belt

Monthly

Verify belt tension. Replace if excessively loose or damaged.

Environment

Quarterly (four

times per year)

Air temperature should not exceed recommended levels. Humidity

where pump is stored should not exceed 70%. Consider relocating

pump if these conditions cannot be met.

Entire Pump

Yearly

Lock unit out and detail clean.

Air Filter(s)

See Comments

Air filters should be changed after the first 100-hour break in period

and every 90 days after that. The frequency will increase in

environments with air contaminants such as dust, paint, dirt, etc.

Oil

See Comments

Oil should be changed after the first 100-hour break in period and

every 90 days after that. This will increase in frequency depending on

actual pump use and hours unit is running.

Oil Filter

See Comments

The oil filter on the unit should be pulled and cleaned with every oil

change.

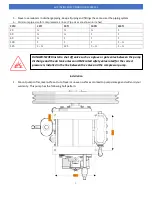

WARNING: Disconnect, tag, and lock out power source the release all pressure from the

system prior to install, service, or relocation.

WARNING: Disconnect, tag, and lock out power source the release all pressure from the

system prior to install, service, or relocation.

Summary of Contents for 5HP

Page 1: ...APP2I0524TP 5HP INLINE PUMP MANUAL REV030921...

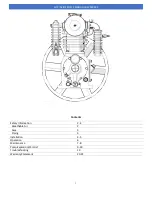

Page 10: ...9 5HP INLINE PUMP MANUAL REV030921 Pump Explosion Parts List...

Page 11: ...10 5HP INLINE PUMP MANUAL REV030921...

Page 12: ...11 5HP INLINE PUMP MANUAL REV030921...

Page 13: ...12 5HP INLINE PUMP MANUAL REV030921...

Page 14: ...13 5HP INLINE PUMP MANUAL REV030921...

Page 15: ...14 5HP INLINE PUMP MANUAL REV030921...

Page 16: ...15 5HP INLINE PUMP MANUAL REV030921...

Page 17: ...16 5HP INLINE PUMP MANUAL REV030921...

Page 18: ...17 5HP INLINE PUMP MANUAL REV030921...