Polar Compressor Rotary Screw Compressors

Revision July.2015

www.eatoncompressor .com

877.283.7614

8 |

P a g e

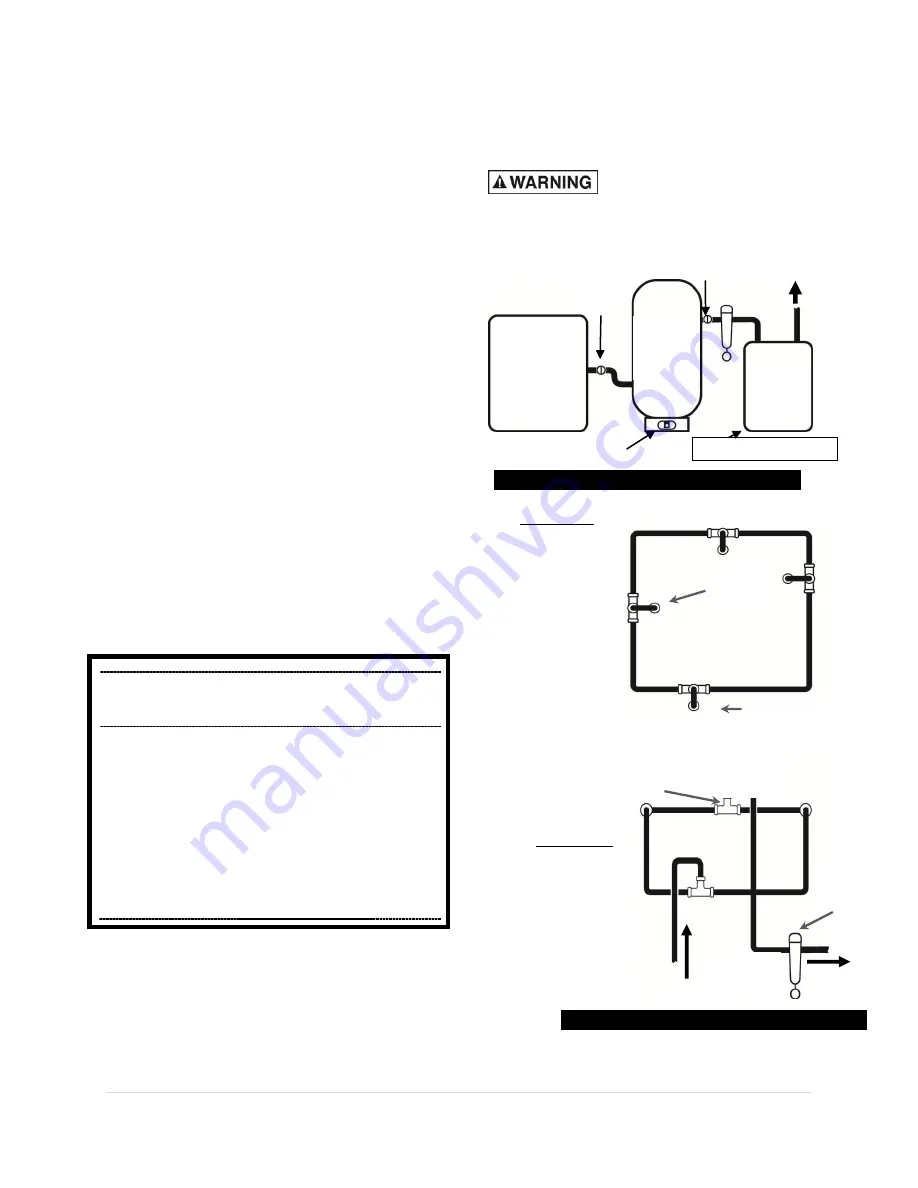

Piping

Safety Steps

1.

Install appropriate flow-limiting

valves as necessary, according to

pipe size(s) and run lengths. This

reduces pressure in case of hose

failure, per OSHA Standard 29 CFR

1926.302(b)(7).

2.

Flow-limiting valves are listed by

pipe size and rated CFM. Select

appropriate valves accordingly, in

accordance with the manufacturer’s

recommendations.

3.

Do not install check valve as

compressor has internal check valve.

Installing

1.

Install piping as shown in Figure 4.

Refer to Figure 5 for recommended,

closed loop installation.

2.

Make sure any tube, pipe or hose

connected to the unit can withstand

operating temperatures and retain

pressure.

Minimum Pipe Size For Compressed

Air Lines

Pipe Size Shown in inches)

Length Of Piping System

SCFM

25 ft. 50 ft.

100

ft.

250

ft.

20

3/4

3/4

3/4

1

40

3/4

1

1

1

60

3/4

1

1

1

100

1

1

1

1-1/4

125

1-1/4

1-1/4

1-1/2

1-1/2

150

1-1/2

2

2

2

200

2

2

2

2

Never use plastic (PVC) pipe

for compressed air. Serious injury or death

could result.

Rotary

Screw

Compressor

Cabinet

Air

Storage

Tank

Air

Dryer

To Shop

Piping

Ball

Valve

Water Drain Valve

Ball

Valve

Figure 4: Basic Piping Diagram

PLAN VIEW

Closed loop

system

Install tee fitting

in piping from air

supply to minimize

pressure drop and

to allow airflow in

two directions.

Air Drop

(typ.)

Air Drop

Install tee fitting with branch to top to

minimize condensation in air drop

ELEVATION

From

Compressor

To Air Tool

Water trap

w/drain

Figure 5: Closed Loop Installation

From Compressor

Auto Drain on back side