11

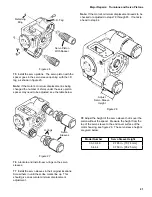

Disassembly

This section describes the complete disassembly,

inspection,and reassembly of the motor. Due to the

complexity of the heavy duty motor certain

subassemblies are disassembled, inspected, and

reassembled upon removal from the motor. This

procedure insures repair accuracy and helps avoid the

loss of small parts.

When major repairs are planned it is recommended that

the process laid out in this section be followed from start

to finish.

1 Clean the exterior of the motor and drain the oil.

2 Position the motor so the shaft seal is accessible.

Important: Cleanliness is extremely important; be sure

that no contaminates get into the motor.

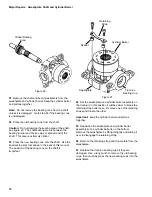

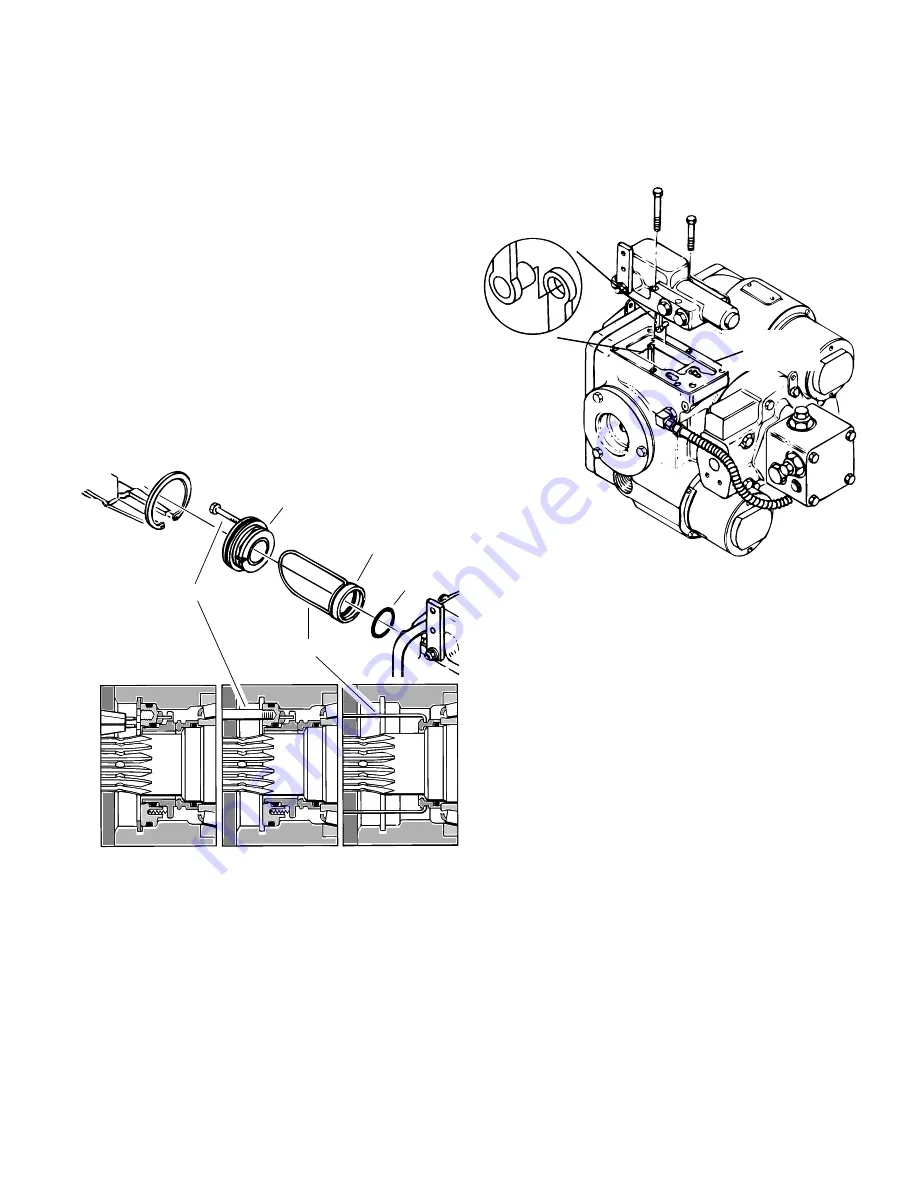

Figure 8

Pulling Tool

O-ring

Rotating Seal

Stationary Seal

Bolt

3 Using a retaining ring pliers remove the retaining ring.

4 Screw a 3 in. X 1/4-20 bolt into the threaded hole in

the stationary seal. Pull on the bolt to remove the seal.

5 Use the special pulling tool, Owatonna Tool Co. P/N

CAS 1844, to remove the rotating seal, see figure 8. If

the special tool is not available pull out the rotating seal

with a wire bent to the shape of the puller.

Note: Detailed drawings of all special tools are given in

the back of this manual.

6 Remove the o-ring; it will either be in the rotating seal

or on the shaft.

7 Remove the six hex head bolts that hold the control

valve to the motor.

8 Lift the control valve away from the motor and

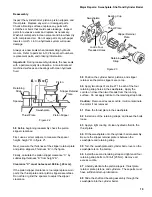

disengage the feedback linkage, see figure 9.

9 Remove the control valve gasket.

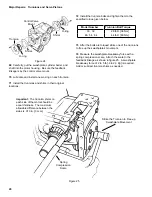

10 Inspect the control valve: Start by thoroughly

flushing the control valve with clean solvent. Then blow

it dry with compressed air. Be sure to blow through all of

the control valve’s internal passages.

Inspect the control valve linkage. Move the control lever

back and forth; it should move freely without binding.

There should be no free play in the feedback link or

control lever.

Check the control valve orifice; if it is plugged after

flushing replace it.

Feedback

Linkage

Control Valve

Gasket

Figure 9

Major Repairs: Shaft Seal and Control Valve

Summary of Contents for 1 Series

Page 31: ...31 Notes...