27

EATON

Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004

Assembly

Valve Block/

Integral Valves

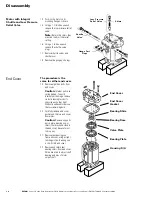

23. Install O-rings and back-up

rings on valve block.

The high pressure ports require

an O-ring and back-up ring. The

O-ring goes on first, then the

back-up ring. The curved side of

ring goes toward the O-ring.

Install square-cut ring in low

pressure drain port of valve

block.

Note:

Be careful not to dam-

age O-rings and back-up rings.

Use clean petroleum jelly to

hold O-rings and back-up

rings in place during block

installation.

24. Position valve block on end

cover. Install four hex bolts.

Torque bolts 28 lb-ft [38 Nm].

Back-up Ring

O-Ring

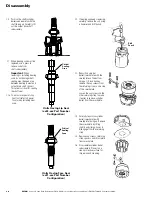

25. Install two outer gauge port plug

assemblies.

Torque to 25 - 31 lb-ft [18 - 23 Nm].

Install center gauge port plug assem-

bly.

Torque to 40 - 48 lb-ft [30 - 35 Nm].

26. Lubricate and install shuttle spool and

shuttle valves. The smaller ends face

the center of the spool.

27. Install the shuttle valve springs and

plugs.

Torque to 68 - 82 lb-ft [50 - 60 Nm].

28. Install the low pressure relief valve

plunger and spring. Lubricate and

insert the shims in the relief valve

plug. Install the plug over the spring,

making sure the shims are not dis-

lodged. Screw the plug in and torque

to 68 - 82 lb-ft [50 - 60 Nm].

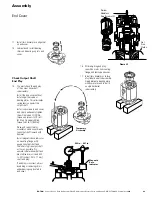

If your motor has an

integral shuttle and low

pressure relief valve,

go to step 25.

If you have a motor with a

valve block, continue with

step 23.

Motor with Integral

Shuttle and Low

Pressure Relief Valve

Motor with Valve Block

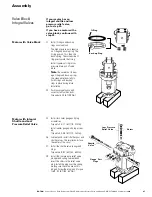

Shims

Low Pressure

Relief Valve

Shuttle

Valve

Gauge Port

Plugs