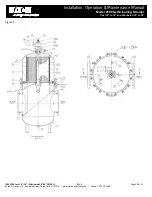

IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 14 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

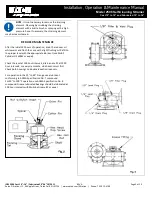

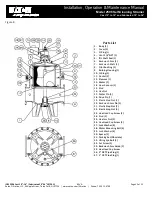

ILLUSTRATION OF TYPICAL idL™ SHAFT SEAL REPLACEMENT

Photo 1:

Gear reducer (gray) mounted

to cut away piece (silver) of the

automatic strainer.

Photo 2:

Internal view of the strainer with

gear reducer removed and the backwash

arm shaft and original packing and packing

gland visible.

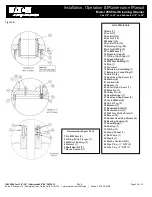

Photo 3

: Internal view of the strainer

with the original packing and packing

gland removed.

Photo 4:

The backwash arm shaft is

cleaned with fine emery cloth.

Photo 5:

The gasket seal is installed over

the backwash arm shaft.

Photo 6:

The quad ring seals and bushing

on top of the idL™ bearing housing

before assembly and installation.

Photo 7:

The seals and bushing have

been assembled into the idL™ bearing

housing and the white PTFE O-ring is

installed.

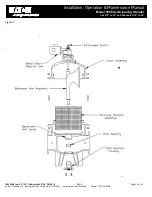

Photo 8:

, The blue plastic shim, taped and

lubricated to the backwash arm, should just

cover the shoulder and help ease the quad

rings over the shoulder of the backwash

arm shaft.

Photo 9:

The completed

idL™ bearing

assembly is installed over the backwash

arm shaft.