IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 15 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

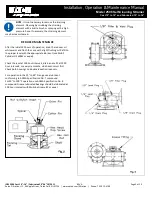

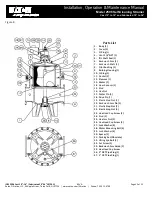

Photo 10:

The idL™ bearing assembly

in place.

Photo 11:

Two allen head cap screws hold

the idL™ bearing seal in place.

Photo 12:

After the idL™ bearing seal is in

place, the gear reducer is replaced on the

top of the strainer.

North America — HQ

44 Apple Street

Tinton Falls, NJ 07724

Toll Free: (800) 656-3344

(North America only)

Voice: +1 732 212-4700

Brazil

Av. Julia Gaioli, 474 – Bonsucesso

07251-500 – Guarulhos

Brazil

Voice: +55 11 2465 8822

Singapore

4 Loyang Lane #04-01/02

Singapore 508914

Voice: +65 6825 1668

For more information,

please e-mail us at

filtrationinfo@eaton.com

or call 732-212-4700.

Europe/Africa/Middle East

Auf der Heide 2

53947 Nettersheim, Germany

Voice: +49 2486 809 0

China

No.7, Lane 280, Linhong Road

Changning District,

Shanghai 200335, China

Voice: +86 21 5200 0422

WARRANTY

All products manufactured by Seller are warranted against defects in material and

workmanship under normal use and service for which such products were designed for a period

of eighteen (18) months after shipment from our factory or twelve (12) months after start-up,

whichever comes first. OUR SOLE OBLIGATION UNDER THIS WARRANTY IS TO REPAIR OR

REPLACE, AT OUR OPTION, ANY PRODUCT OR ANY PART OR PARTS THEREOF FOUND TO BE

DEFECTIVE. SELLER MAKES NO OTHER REPRESENTATION OR WARRANTY, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. WE SHALL NOT BE LIABLE FOR CARTAGE, LABOR,

CONSEQUENTIAL DAMAGES OR CONTINGENT LIABILITIES. OUR MAXIMUM LIABILITY SHALL NOT

IN ANY EVENT EXCEED THE CONTRACT PRICE FOR THE PRODUCT.