IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 2 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

RECEIVING,

HANDLING,

AND

INSPECTION

Prior to shipment, strainers are coated internally and on

external machined surfaces to protect against rust. All openings

are covered and the motor-reducer unit wrapped with plastic

and secured with waterproof tape. The motor is packed

separately.

1.

Unpack the strainer and inspect for damage occurring

during transit. Report damage to the carrier. If the strainer

is not installed immediately, see “Storage” instructions.

2.

Remove preservatives with solvent-dampened cloths.

Exercise care when using solvent.

3.

Verify the rated pressure and temperature on the strainer

nameplate is not less than the maximum pressure and

temperature of the system.

4.

The rated pressure shown on the nameplate is the

maximum pressure, including shock, at which the strainer

may be operated

5.

Check to be sure the available electrical power matches

the voltage, phase and cycle requirements of the strainer

motor and automatic control panel.

6.

Remove flange and thread protectors. Check for and

remove any foreign or loose materials such as blocking,

desiccant bags, etc. that could be carried downstream

when fluid is introduced into the strainer.

STORAGE

Whenever possible, store strainers indoors in a clean, dry

environment. Replace all protective wrappings, flange

protectors, plugs, etc. which may have been removed during

receiving inspection.

Outdoor storage, if unavoidable, requires special treatment.

a.

Place a bag of silica-gel or similar desiccant in each strainer

to absorb moisture (attach to inside of flange protectors).

b.

Reapply rust preventative to any machined surface which

became exposed due to handling and/or receiving

inspection.

c.

Make sure all openings are covered. Seal flange protectors

with waterproof tape.

d.

Wrap motor-reducer unit with plastic and secure with

tape. Permit air circulation or provide adequate desiccant

for moisture control.

e.

Protect the entire strainer with heavy polyethylene wrap

and seal with waterproof tape.

CAUTION:

Before strainers are put into operation

after storage be sure to remove all desiccants,

protective bags, caps, plugs, etc. Inspect gasketing

and shaft seals for possible deterioration and

replace as required. Inspect oil level in reducer and check

lubricant for accumulated condensation.

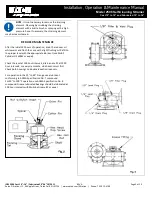

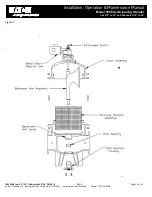

INSTALLATION

Position the strainer in the line so that the fluid enters the

connection marked inlet

.

CAUTION:

Any alteration to the piping between

the pump and the strainer could affect the

performance of the unit. Lift strainer with slings

under the inlet and outlet connection.

Be sure sufficient headroom is provided for easy removal of the

internal parts. Refer to sales drawing for removal clearance.

NOTE

: Clearance for rigging equipment must also

be considered.

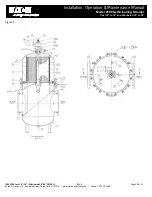

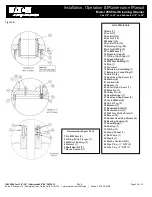

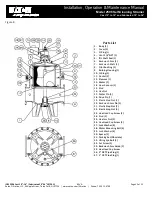

Support the strainer in the line as follows:

Both cast and fabricated strainers are provided with mounting

feet. The footpads are drilled to accommodate the use of

anchor bolts. Place the strainer in the line on concrete or steel

mounts. Do not support the strainer or the piping coming to

and from the strainer by the line flanges and flange bolting. See

Fig 1(cast) or Fig 5 (fabricated) and sales drawing.

Connect the strainer to the line. Use the same type flange

faces. For example, do not bolt raised face flanges to iron flat

face flanges. Iron flanges must be flat face with full face

gaskets.

Strainers are subject to fact-to-face variations due to machining

and fabrication tolerances. Prefabricated piping systems must

allow adjustment at the strainer connections.