IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 3 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

Be sure flange gaskets are in place and fasteners are tight.

Inspect all external components of the operating mechanism

for damage due to handling and shipping. Manually rotate the

backwash arm to observe proper alignment.

To operate manually and determine freedom of movement,

see “Manual Operation of Backwash Arm”, page 6. If backwash

arm rotates freely proceed with installation.

If binding occurs, follow “Removal of Cover and Operating

Mechanism Assembly” procedures contained on page 6 and

rectify cause of binding.

Follow “Reassembly of Cover and Operating Mechanism

Assembly” procedure on page 6. Then proceed with

installation

.

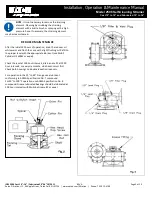

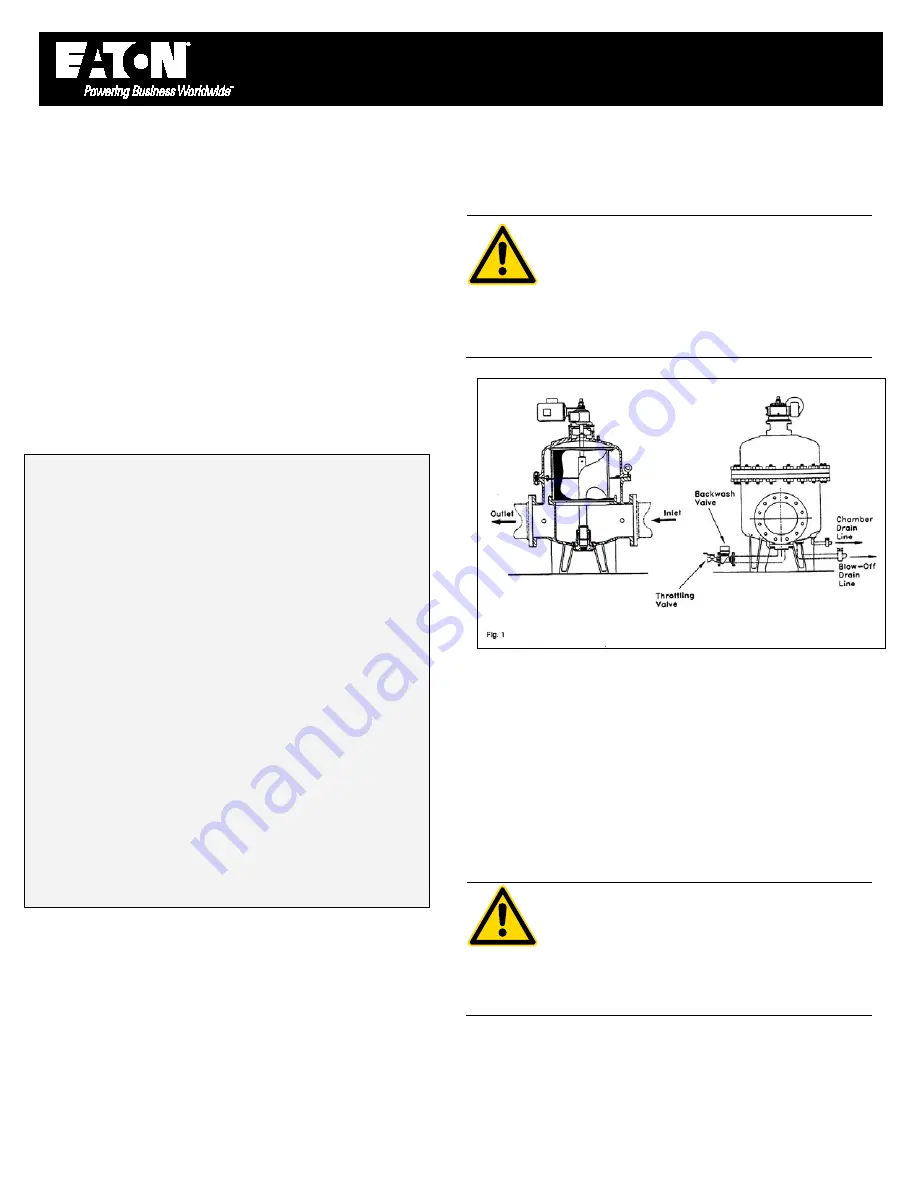

For Fabricated Strainers:

Attach the blow-off/drain line to the NPT coupling in the center

of the bottom head. See Figure 1. Install a ball, gate or plug

valve in this line. Keep this valve closed except when necessary

to drain the strainer or blow-off debris settled on the bottom.

Attach the backwash line to the side flanged opening. It is

important to prevent backpressure by having a short, free

flowing backwash line with no vertical risers and a minimum of

bends.

For Cast Strainers:

Attach the chamber drain line to the 1” NPT threaded opening

on the outer edge of the filter. See Fig 1.

Attach the blow-off drain line to the offset 2” NPT opening. See

Fig 1. Install a manually operated ball, gate or plug valve in this

line. Keep this valve closed except when necessary to drain the

strainer or blow off debris settled on the bottom.

Attach the backwash line to the center 2” NPT or 2” 150# ANSI

flanged opening. It is important to prevent back pressure by

having a short, free flowing backwash line with no vertical

risers and a minimum of bends.

Install a backwash control valve in this line. The valve may be

manually or automatically operated. It is recommended that it

be used only for full-on/full-off control except for high pressure

or mesh screen applications in which the backwash control

and/or throttling valve should be adjusted to a flow rate which

attains thorough cleaning only.

Connect power source to the strainer motor. Note: It is

advisable to use flexible power cable with extra length to allow

for strainer cover removal without having to disconnect the

motor.

CAUTION:

Be sure power source matches motor

requirements. Damage may occur if improperly

connected. Motor starter should incorporate a

thermal overload device to protect the motor.

Interlock strainer motor with process fluid service pump where

feasible. Install a fusible disconnect or circuit breaker on the

incoming power service.

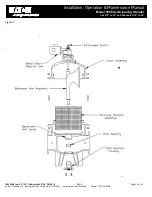

START-UP

Check the reducer for lubricant. Fill unit to pipe plug level with

proper oil if level is low. See “Reducer Maintenance” section on

page 5.

Install or open reducer vent which has been plugged to prevent

lubricant loss during shipment. Loosen packing gland nuts.

Energize strainer motor and/or controls. Open vent on strainer

cover. Slowly introduce fluid to be strained.

CAUTION:

The initial start-up should be done

while in the continuous backwash mode. Once the

system has been purged of all initial construction

debris, the automatic mode can be activated. The

thordon bearing is lubricated by liquid to be strained. DO NOT

operate for long periods before strainer is filled with fluid. Do

not over tighten the packing gland nuts.

Close strainer vent when air is expelled and fluid begins to flow.