IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 4 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

NOTE

: Good operating practice dictates that the

operator observes the strainer carefully for several

weeks to determine the best operating mode, that

is, continuous or intermittent backwash. Refer to

“Self-Cleaning Strainer Control Panel Instructions” provided

with such equipment.

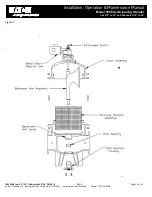

OPERATION

Operate the strainer in the continuous mode only, unless

controls for intermittent operation have been provided and

energized.

Normally the drain valve is left in the closed position.

Approximately once each week adjust this valve to the full

open position for two to three minutes to remove any settled

debris on the strainer bottom. Frequency of this operation is

dependent upon the type and amount of entrained solids in the

liquid.

Take daily readings of the pressure drop across the strainer to

ensure proper operation.

CAUTION:

Total pressure drop in excess of 15

psig is a warning signal requiring investigation and

corrective action. Permanent damage may result

if operated in excess of 15 psig.

I

F THIS SHOULD OCCUR

:

Check strainer to be sure that backwash

arm is rotating (if not see section on Trouble Shooting, page 9).

Check backwash line for restrictions. Valves in this line should

be opened full except for high pressure or mesh screen

applications in which the backwash control and/or throttling

valve should be adjusted to a flow rate which attains thorough

cleaning only.

Position blow-off/drain valve to the full open position for two

to three minutes to clear the strainer of accumulated debris.

Adjust the timer, in the control panel to increase the duration

of the backwash.

Should the pressure drop still remain above normal when the

backwash is operating, close the outlet valve and open the

backwash valve full for several minutes. If upon resuming flow

thru the unit, the pressure drop is not normal, the strainer

should be shut down.

NORMAL

SHUT-DOWN

When necessary to shut-down the system:

1.

Backwash the strainer for at least six minutes to clean the

straining elements.

2.

Close the main flow valves fully open the blow-off/drain

valve and the vent on the strainer cover. The chamber

drain valve should also be fully opened.

3.

De-energize strainer motor and/or controls.

4.

Follow standard maintenance procedures contained

herein. Do not allow the straining elements to dry while

dirty.

EMERGENCY

SHUT-DOWN

1.

To quickly shut-down the system, close the main inlet and

outlet flow valves.

2.

Open the blow-off/drain valve “full” and open the vent on

the cover. Open the chamber drain valve.

3.

De-energize strainer motor and/or controls.

4.

Follow standard maintenance procedures as soon as

possible. Do not allow the straining elements to dry while

dirty.

STANDARD

MAINTENANCE

I

NTERNALS

At normal plant intervals, the strainer should be disassembled

for internal inspection (refer to “Normal Shut-Down”

procedures, page 4).

Follow “Removal of Cover and Operating Mechanism

Assembly” procedures, page 6.

Inspect assembly for damage or deterioration due to normal

operation. Examine straining element and check for mechanical

damage or blinding.

Clean straining element thoroughly.