IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 6 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

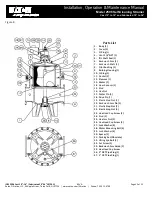

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

MANUAL

OPERATION

OF

BACKWASH

ARM

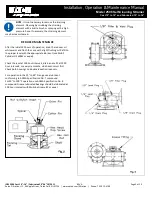

The Model 2596 is furnished with a removable drive key to

facilitate manual operation.

1.

De-energize the power supply to the strainer motor.

Remove the hair cotter pin and tap out drive pin from shaft

(see Fig 2).

2.

Hold shaft flat with adjustable wrench and back off the

lock nut 1/2 turn.

3.

The backwash can now be rotated manually. Manually

open the backwash control valve (manual cleaning only).

4.

Place a wrench on the flats at the top of the shaft and

rotate the backwash arm at approximately 5 RPM as often

as required to maintain a low pressure drop (manual

cleaning only). One turn minimum for pre-startup.

5.

To return the strainer to normal operation first close the

backwash control valve (manual cleaning only).

6.

Align the cross hole in the B/W shaft with gear reducer by

rotating the drive shaft.

7.

Insert drive pin in B/W arm shaft and secure with hair

cotter pin.

8.

Tighten lock nut.

9.

Energize the power supply to the strainer drive motor.

The strainer is now ready for operation

.

DISASSEMBLY

&

PARTS

REPLACEMENT

PROCEDURES

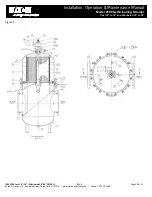

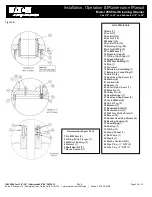

The Model 2596 may be disassembled entirely without removal

from the pipeline to permit examination or replacement of any

individual part. Refer to this manual and the included assembly

drawings for the location of parts.

CAUTION:

Do not perform any maintenance on

this strainer until normal shut down procedures

have been performed.

REMOVAL

OF

COVER

AND

OPERATING

MECHANISM

ASSEMBLY

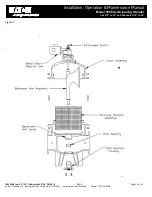

This assembly can be removed as a complete unit. Refer to

“Normal Shut-Down” procedures.

NOTE:

To ensure ease of assembly and avoid

damage to element, all legs of sling must be of

equal length.

1.

Disconnect power source and remove fuses.

2.

Disconnect electrical connections to the motor.

3.

Remove the cover nuts on cast strainers or loosen swing

bolt nuts and swing bolts to clear blocks on fabricated

strainers.

4.

Lift the cover assembly gently, using the cover lifting lugs

on fabricated strainers or the cover lifting eyes on cast

strainers. These lifting lugs/eyes are for the cover

assembly. Note: See “Installation” procedures to lift

strainer.

5.

All internal parts may now be inspected for deterioration,

wear or blockage and replaced or repaired as necessary.

Inspection should include the element and bushing. The

replacement procedures for the reducer, motor and filter

are contained herein.

REASSEMBLY

OF

COVER

AND

OPERATING

MECHANISM

ASSEMBLY

Examine cover O-ring seal and replace O-ring if necessary.

Refer to “Replacement or Maintenance of Filter Element on

Page 7.

CAUTION:

Do not use excessive force on the

backwash arm. Disconnecting the shaft from the

reducer also disconnects the shaft from the

protection of the motor overloads. If excessive

resistance is met, rotate in the opposite direction to dislodge

any wedged debris. If this does not work, the cover must be

removed and the source of blockage cleared away.