IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 7 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

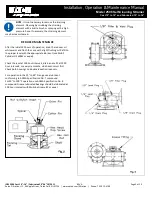

MOTOR

REPLACEMENT

(Refer to “Normal Shut-Down” procedure)

1.

Disconnect power source and remove fuses.

2.

Disconnect motor leads.

3.

Remove bolts holding the motor to the reducer.

CAUTION:

Do not allow the motor to drop, or its

weight to rest, on the output shaft.

4.

Remove the key from the motor output shaft.

5.

Install the key on the new motor, install the new motor on

the reducer and secure with motor mounting cap screws.

6.

Reconnect the motor leads. (Direction of rotation is not

important).

7.

Replace fuses and connect power.

SHAFT

PACKING

REPLACEMENT

(SEE IDL SHAFT SEAL INSTRUCTIONS)

REPLACEMENT

OR

MAINTENANCE

OF

ELEMENT

&

BACKWASH

ARM

BUSHING

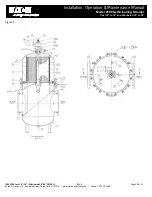

(See Figs 5 & 6, pages 10 & 11 for fabricated strainers or Figs 7

& 8 pages 12 & 13 for cast strainers) The Model 2596 is

furnished with a removable element secured to a support ring

by four roll pins. The support ring is secured to the cover by

four bolts, washers and locknuts.

Refer to “Removal of Cover and Operating Mechanism

Assembly”, page 6.

Fabricated Strainers

Lift the cover assembly from the body and lower cover

assembly to supports placed under support ring. Remove the

four bolts between the support ring and cover, then lift the

cover assembly. See Fig 4

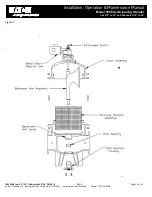

Inspect the element, sealing surfaces and bushing located at

bottom of backwash arm. Clean element and sealing surfaces

as required. Remove existing element by removing the roll pins.

Replace element by aligning the element tab holes with the

support ring holes and replace the roll pins. Replace backwash

arm bushing as required.

Lower the cover and backwash arm assembly into the center of

the support ring/element assembly. Secure cover to support

ring with bolts, washers, and locknuts.

Lift cover assembly and place into body.

Cast Strainers

Lift the cover assembly from body. With two supports placed

below the element, lower the assembly as close to the supports

without touching, and then remove the four bolts allowing the

element to rest on support horses. See Fig 4A.

Clean sealing faces in body and cover. Inspect gaskets and

replace if necessary.

Lower cover assembly onto new or existing element until bolts

and elastic stop nut can be fastened together. Tighten

diagonally until element is firmly and evenly seated in cover.

Replace stop nuts after 3 disassembles.

Lift cover, B/W assembly and filter and place into body. Once

the B/W arm guide is properly seated on the bottom bearing

housing, the cover flange will come into full contact with the

body flange.

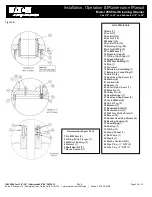

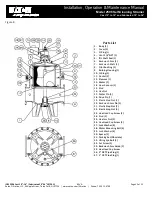

Lifting Device

Cover

Backwash Arm

Hex Bolts & Washers

Straining Element

Hex Nuts & Washers

Lower Support Ring

Roll Pins

Supports

Figure 4