IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 8 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

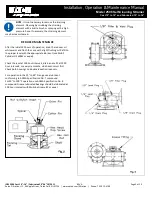

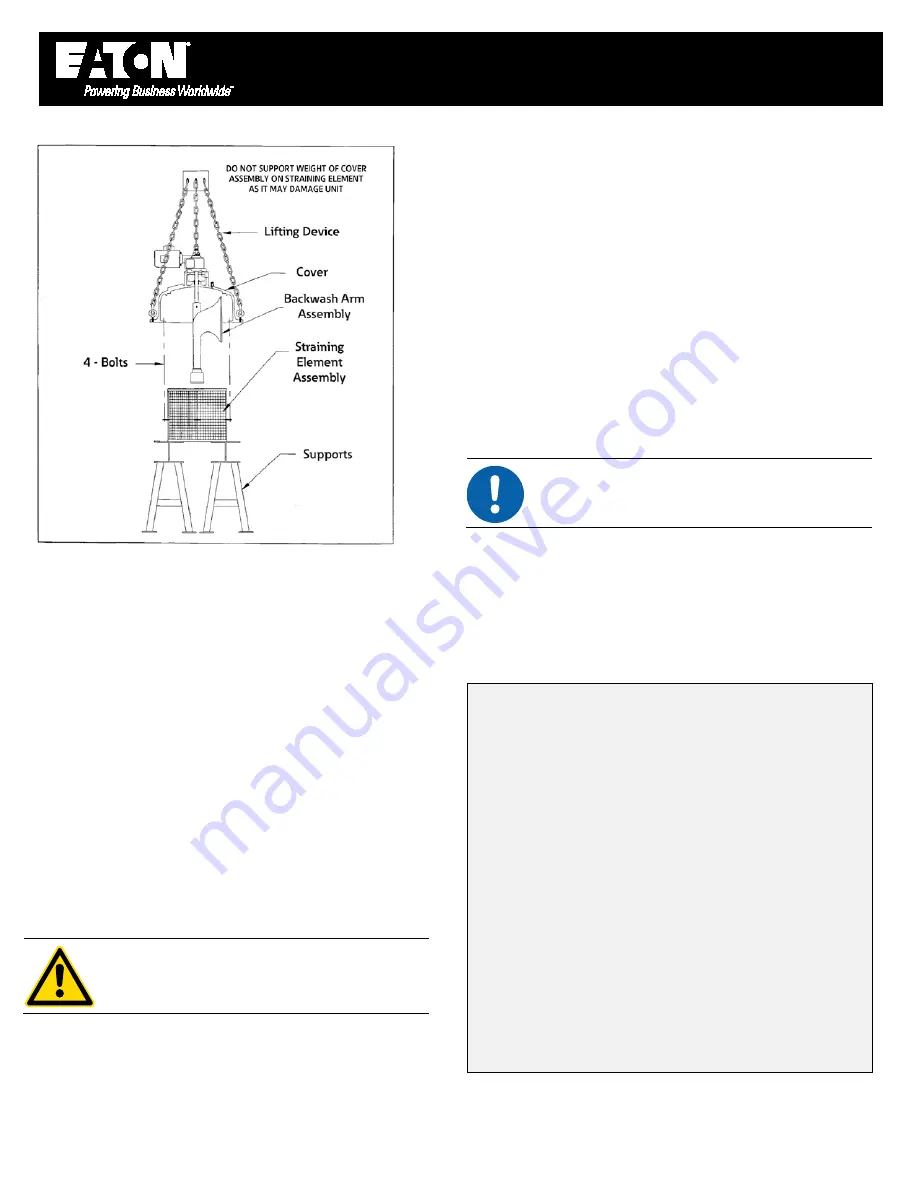

Fig 4A

Before tightening swing bolts, rotate manually to ensure

freedom from binding. See “Manual Operation of Backwash

Arm”, page 6.

1.

Align cover and body bolt blocks and secure with swing

bolts.

2.

Connect the electrical leads to the motor. Please note that

the direction of rotation is not important.

3.

Install fuses and connect power source.

4.

The unit is now ready for operation.

Refer to “Start-Up” procedures on page 3.

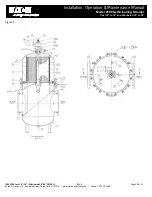

REDUCER

REPLACEMENT

(See Fig 3)

1.

Disconnect power and remove motor leads. Remove motor

flange bolts and washers and remove motor.

CAUTION:

Do not permit the motor to drop or

allow its weight to rest on the drive shaft.

2.

Remove the hair cotter pin and tap out drive pin from the

shaft (see Fig 2).

3.

Remove the locknut and spacer.

4.

Remove the cap screws and washers securing the reducer

to the reducer mount and remove the reducer.

5.

Position the new reducer in place with input shaft parallel

and opposite the strainer inlet nozzle. Secure with

fasteners.

6.

Replace spacer and locknut. Tighten locknut until step on

backwash arm shaft is in contact with the sleeve of the

reducer.

Follow Manual Operation of Backwash Arm, page 6.

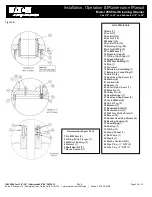

REMOVAL

OF

ORIFICE

PLATE

(IF

APPLICABLE)

NOTE

: Certain applications may use an orifice plate

on backwash arm.

The orifice plate can be removed with the backwash arm and

filter element in place by removing the screws attaching the

orifice plate to the backwash arm then sliding the orifice plate

out.

PILOT

BUSHING

&

HOUSING

REPLACEMENT

Cast Strainers Only:

To replace the pilot bushing:

1.

Disconnect the power to strainer drive motor. Isolate the

strainer then drain inner chamber.

2.

Disconnect and remove part of the backwash line to allow

removal of bushing housing.

3.

Remove 3/4 cap screws (4 or 8) and drop guide bushing.

This can be done with backwash arm in place if necessary.

4.

Old guide bushing can be removed by cutting or drawn out

with an extractor tool. Care must be taken not to damage

housing wall.

5.

After cleaning, insert new guide bushing using a wood

block to tap it into housing.

6.

Before replacing the guide bushing assembly, check the O-

ring seal and replace if necessary.