IOM

Controls 04/2020

REV B.

Page

4

of 9

Eaton Filtration LLC,

44 Apple

Street, Tinton Falls,

NJ

07724 www.eaton.com/filtration

Phone:

732-212-4700

Installation, Operation & Maintenance Manual

Control Panels for Automatic Self-Cleaning Strainers

Model 596 and Model 2596

DIFFERENTIAL PRESSURE SWITCHES

SWITCH DESCRIPTION

(SINGLE OR DUAL ELEMENT)

A diaphragm type differential control with single switch is

standard. It initiates a backwash cycle whenever a high

differential pressure drop occurs across the strainer. A dual

element switch is optional where operation requires the first

switch to initiate the backwash cycle. The second switch

activates on further increasing differential pressure and

energizes a visual or audible alarm, calling for operator

assistance.

DIFFERENTIAL PRESSURE SWITCHES

The differential pressure switch easily mounts on the

control panel supports or attached to a bracket that is

welded to the strainer body.

CAUTION:

Never drill into the strainer body

to mount instrumentation or support

brackets.

CAUTION:

Welding brackets to cast iron units

is not recommended and should be avoided.

The switch is piped to the pressure connections furnished on

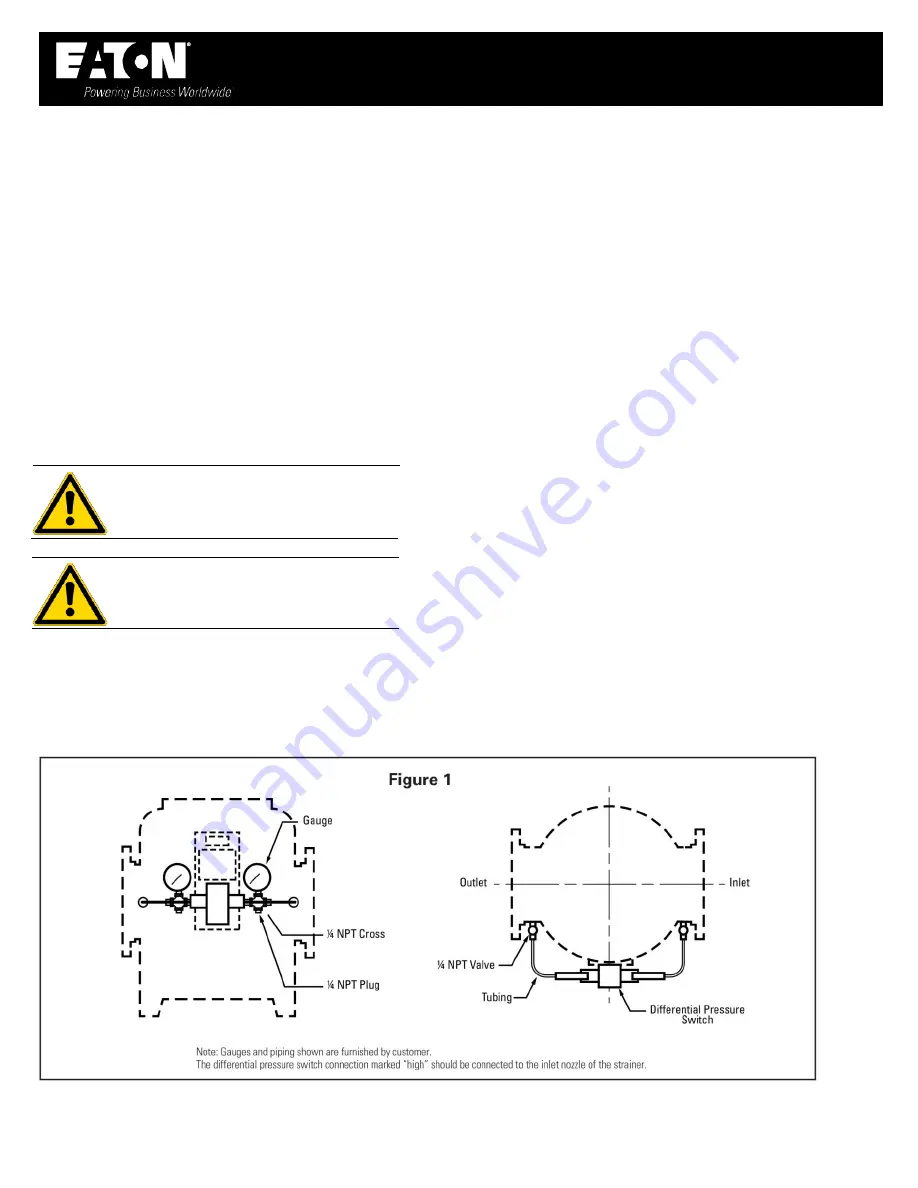

the inlet/discharge nozzles of the strainer as shown in Fig 1.

Customer must supply and run wiring and conduit between the

differential pressure switch and the control panel. See Fig 2 for

wiring connections.

DIFFERENTIAL SWITCH ADJUSTMENT

While it is possible to use other equipment than what is

described below, any installation should have the items

described here.

Equipment to be furnished by customer:

2 calibrated pressure gauges

2 gauge valves with drain

2 tees, tubing, and fittings

All items suitable for

1/4”

NPT connections

Install all equipment as shown in Fig 1. Open the gauge valves

and record the pressure readings at inlet/discharge of strainer

operating at rated flow. The difference in reading is the

“N

orm

al”

pressure drop across the system. Close both gauge

valves. Set switch at

“N

ormal Plus 2 ps

i”

using the adjustment

screw at the calibrated scale. To simulate a high differential

pressure, carefully vent the

“

ou

tlet”

side gauge valve only.

Note the pressure difference at which the switch is

“

activated

.”

Using the adjustment screw on top of the switch, adjust until

switch activates at the proper set point. The

“High”

alarm

setting (optional) should be set at

“N

ormal Plus 4 ps

i.”

Special

applications may require other settings than those given above.

Switch should be re-calibrated at least every 6 months

.