IOM

Controls 04/2020

REV B.

Page

6

of 9

Eaton Filtration LLC,

44 Apple

Street, Tinton Falls,

NJ

07724 www.eaton.com/filtration

Phone:

732-212-4700

Installation, Operation & Maintenance Manual

Control Panels for Automatic Self-Cleaning Strainers

Model 596 and Model 2596

OPERATING MODES

DESCRIPTIONS

OFF MODE

Power light illuminated; 120 VAC power applied across

the “common” and “close” valve terminal connection.

No other circuits energized.

ON MODE

Backwash valve open, strainer motor running,

"BACKWASH ON" indicator illuminated, (monitor

differential pressure switch, if differential pressure

closes then

“HIGH DIFFERENTIAL”

indicator

illuminated, HI-DP alarm contact closes).

AUTO MODE

Timer range limits for BACKWASH ON (valve open) is 1

to 1440 minutes.

Timer range limits for BACKWASH OFF (valve closed) is

1 to 1440 minutes.

CHANGING THE BACKWASH

TIMER SETTINGS

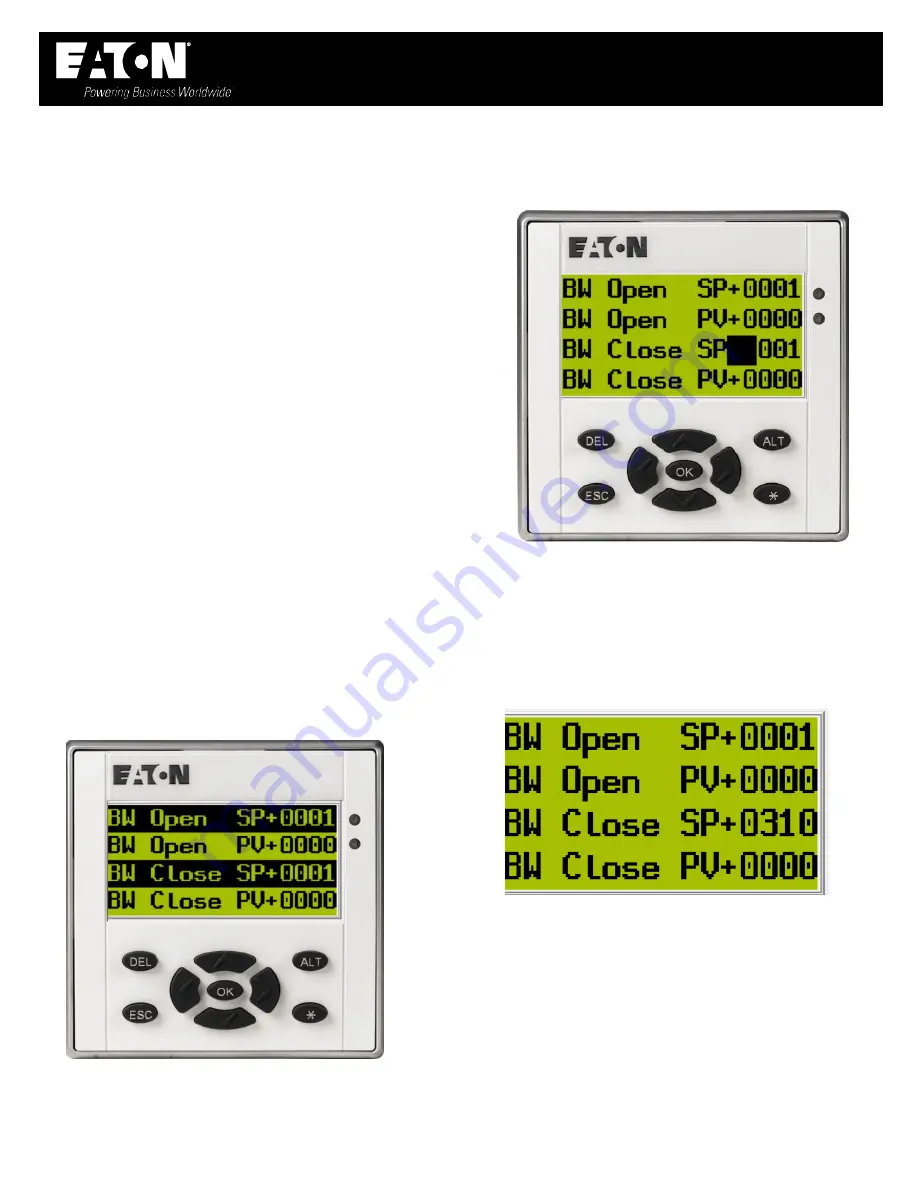

To change timer settings press ALT button.

Use the UP or DOWN arrow buttons to move the cursor to

select lines

“

BW Open SP+

”

or

“

BW Close SP+

”.

Press OK button to edit the BW set point.

Use UP and DOWN arrow buttons to increase or

decrease value in selected number column.

Use LEFT and RIGHT arrow buttons to select the number

column.

When the value is completed (shown set for 310

minutes/seconds above), press the OK button to move

the cursor to BW timer set point select mode. Then

press ESC key to leave BW timer edit mode.