I.B. 3A74791H04

Page 26

Effective 7/97

SECTION 6: INSPECTION, MAINTENANCE

AND TROUBLESHOOTING

6-1 INTRODUCTION

• DO NOT WORK ON A CIRCUIT BREAKER IN THE

“CONNECTED” POSITION.

• DO NOT WORK ON A CIRCUIT BREAKER WITH

SECONDARY DISCONNECTS ENGAGED.

• DO NOT WORK ON A CIRCUIT BREAKER WITH

SPRINGS CHARGED OR CONTACTS CLOSED.

• DO NOT DEFEAT ANY SAFETY INTERLOCKS.

• DO NOT LEAVE MAINTENANCE TOOL IN THE

SOCKET AFTER CHARGING THE CLOSING

SPRINGS.

• DO NOT STAND LESS THAN FOUR METERS

AWAY FROM THE BREAKER WHEN TESTING

FOR VACUUM INTEGRITY.

FAILURE TO FOLLOW ANY OF THESE INSTRUC-

TIONS MAY CAUSE DEATH, SERIOUS BODILY

INJURY, OR PROPERTY DAMAGE. SEE SECTION 2-

SAFE PRACTICES FOR MORE INFORMATION.

6-2 FREQUENCY OF INSPECTION AND

MAINTENANCE

Periodic inspections and associated maintenance are

essential to the safe and reliable operation of W-VAC

Vacuum Circuit Breakers. The inspection frequency and

associated maintenance recommended are intended to

insure the best possible ongoing service. It is imperative

that an established schedule be followed. To establish

an exact schedule for a specific installation, use the fol-

lowing guidelines:

1. In a clean, non-corrosive environment, inspect and

maintain each circuit breaker annually or every 500

operations, which ever comes first.

2. For special conditions such as frequent circuit break-

er operation, contaminated environments, and high

temperature/humidity conditions, the inspection fre-

quency should be twice a year.

3. Inspect a circuit breaker every time it interrupts fault

current.

4. Follow the steps presented in Paragraph 6-3 entitled

“Inspection and Maintenance Procedures” for sched-

uled programs.

5. Create and maintain a dated permanent record of all

inspections, maintenance performed, actions taken,

observations made, and measurements taken. Not

only will this provide valuable historical information, it

can help to establish whether or not the present

schedule needs to be adjusted.

6. Perform ongoing visual inspections, when possible,

of all equipment on a regular basis. Be alert for an

accumulation of dirt in and around the circuit break-

ers, loose hardware or discolored insulation.

6-2.1 QUALIFIED PERSONNEL

For the purpose of operating switchgear equipment and

associated circuit breakers, only individuals thoroughly

trained in the operation of power circuit breakers and

associated equipment, and having knowledge of con-

nected loads may be considered to be qualified. Refer

to further definitions in any applicable codes.

For the purpose of inspecting and maintaining such

equipment, a qualified person must also be trained in

regard to the hazards inherent to working with electricity

and the proper way to perform such work. Such an indi-

vidual should be able to de-energize, clear and tag cir-

cuits in accordance with established safety practices. In

addition, these individuals should have access to and be

trained in the use of protective equipment, such as rub-

ber gloves and flash clothes.

All personnel should be familiar with and understand the

material presented in this instruction manual and other

related manuals.

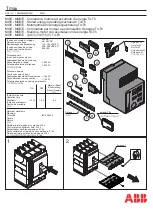

6-2.2 HELPFUL TOOLS AND ACCESSORY ITEMS

To simplify the performance of inspection and mainte-

nance programs, the items described in Section 3-5 are

recommended.

6-2.3 GENERAL TORQUE GUIDELINES

Bolts and screws must be properly torqued. This is

especially true if parts and/or accessories are added or

replaced. Table 6.1 provides guidelines on torque lev-

els. The table is intended as a general guideline and

!

WARNING

Summary of Contents for 360 W-VAC 16

Page 2: ......