18

Instruction Book

IB02707112E

August 2015

50/75VCPW-VSR

Breaker To Vacuum Starter Replacement Unit

EATON CORPORATION www.eaton.com

procedures are similar. If it is necessary to reference anything in the

unit compartment, refer to the original instruction books supplied

with the assembly.

Refer to Figures 3.3 and 3.4, for any parts identification required

during these installation procedures.

a. The starters faceplate and barriers must be positioned properly

and securely bolted in position, as shown in Figures 3.3 and 3.4,

before inserting the starter into the cell.

b. Carefully follow the insertion procedure in section 5 to get

the VSR unit into the test position inside the compartment and

to engage the secondary contacts to proceed with the electrical

operations check.

WARNING

AS SOON AS THE SECONDARY CONTACTS MATE UP, THE STARTER IS

READY FOR OPERATION IF THE CONTROL CIRCUIT IS ENERGIZED.

c. Once the starter is in the test position, it may be electrically

closed and tripped by using a control switch on the cell door, or it

may be manually tripped by means of the trip button, located on the

faceplate of the starter.

5.9 CELL CODE / REJECTION PLATE INSTALLATION

Cell code plates and circuit breaker rejection plates are required to

reject circuit breakers and breaker to vacuum starter replacement

units that do not match the electrical rating structure of the existing

cell. If the momentary rating of a unit is increased, a code plate and

a cell rejection plate must be installed to accept the new unit and

reject all others of lesser ratings. If momentary ratings of the new

unit is the same as the original breaker, then the original cell code

plate may be retained.

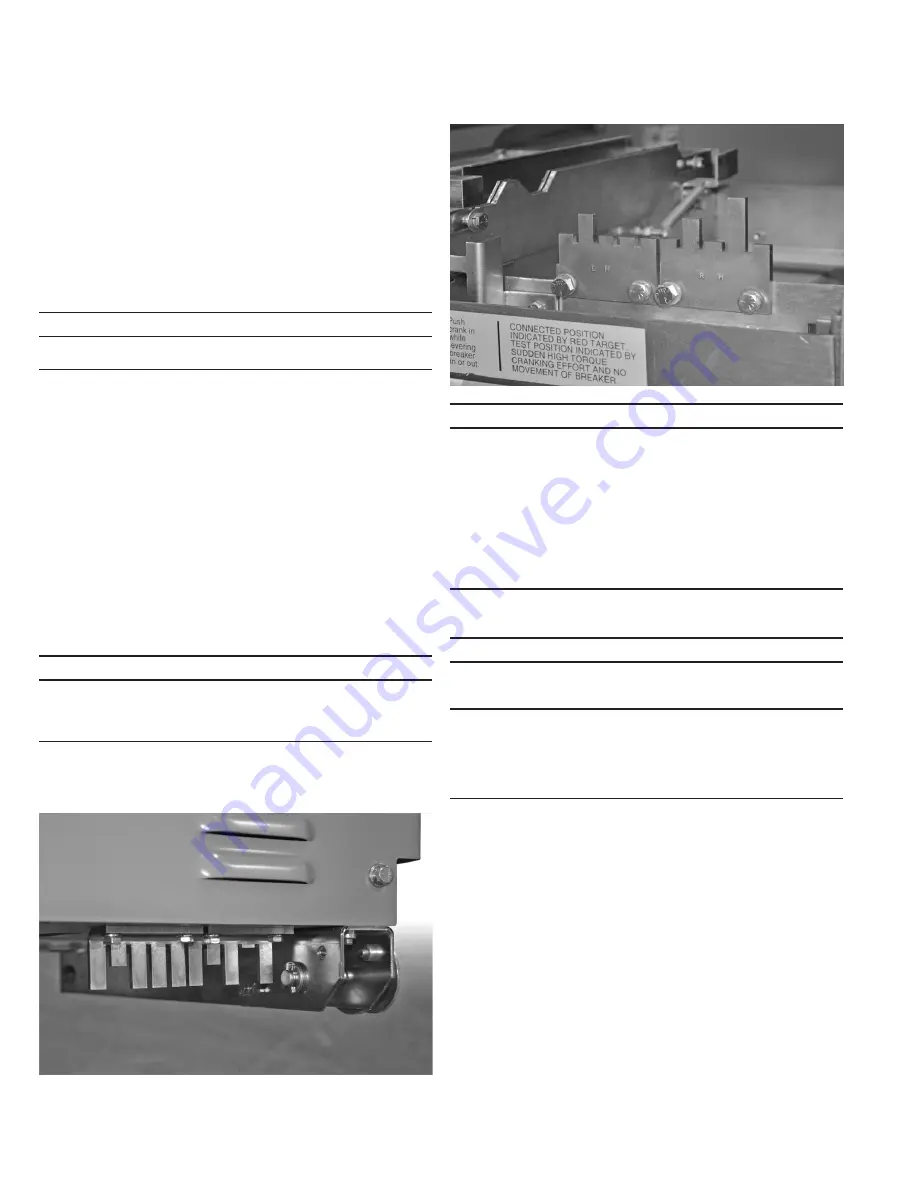

A unit code plate is factory installed on VSR-series units. Cell code

plates are automatically furnished with each unit. (Rejection plates

have stamped orientation as “LH” and “RH” for clarity.) (Figure 5.5)

NOTICE

REJECTION PLATES MUST BE INSTALLED INTO THE PROPER INTENDED

SWITCHGEAR PER THE NAMEPLATE RATING. IF THE REJECTION PLATE IS

NOT INSTALLED CORRECTLY THE VSR CAN NOT BE INSERTED INTO THE

INTENDED STRUCTURE.

WARNING

ARC FLASH INCIDENCES WITH MV SWITCHGEAR CAN OCCUR DURING THE

PROCESS OF INSERTING AND REMOVING VSR UNITS IN SWITCHGEAR

CUBICLES. IT IS STRONGLY RECOMMENDED THAT PROPER PPE

(PERSONAL PROTECTIVE EQUIPMENT) BE WORN BY PERSONNEL WHO

RACK UNITS USING THE MANUAL RACKING HANDLE OR THE ROTARY

RACKING HANDLE. EATON CORPORATION PROVIDES A UNIVERSAL

REMOTE POWER RACKING SYSTEM (RPR-2) WHICH IS COMPATIBLE WITH

THE INTERNAL ROTARY RACKING UNITS. THIS SYSTEM MAY ALLOW

PERSONNEL TO WEAR A LOWER LEVEL OF PPE DURING THE INSERTION

OR REMOVAL PROCESS AS LONG AS RACKING CAN BE PERFORMED FROM

OUTSIDE THE FLASH PROTECTION BOUNDARY.

5.10 INSERTION PROCEDURE

WARNING

EXAMINE THE INSIDE OF THE CELL BEFORE INSERTING THE STARTER

FOR EXCESSIVE DIRT OR ANYTHING THAT MIGHT INTERFERE WITH THE

STARTER TRAVEL.

KEEP HANDS OFF THE TOP EDGE OF THE FRONT BARRIER WHEN PUSHING

A STARTER INTO A CELL. FAILURE TO DO SO COULD RESULT IN BODILY

INJURY, IF FINGERS BECOME WEDGED BETWEEN THE STARTER AND

THE CELL. USE BOTH FULLY OPENED HANDS FLAT ON THE FRONT OF THE

STARTER TO ADVANCE INO THE STRUCTURE.

If the VCPW-VSR is being inserted into an upper compartment or

will be positioned in a lower compartment without the use of a

drawout ramp or dockable dolly, the extension rails must first be

put in position. Carefully engage the left and right extension rails to

the fixed structure rails and ensure they are properly seated in place

(Figure 5.6). Once the extension rails are properly in place, the VSR

can be carefully loaded on the extension rails using an overhead lifter

and lifting yoke. Remove the lifting yoke when the VSR is securely

seated on the extension rails.

Push the VSR into the compartment until the TEST position is

reached as confirmed by a metallic sound of the racking latch

engaging the racking nut (Figures 5.7). Once the VSR is in the TEST

position, the extension rails can be removed.

To engage the secondary contacts, raise the handle to the

secondary disconnect cage and pull the cage forward as far as

possible (Figure 5.8). As soon as control power is available, the

motor will start charging the closing springs.

Figurt 5.5. VCPW-VSR RtjtcoiNn Plaot (230A VSR ShNwn)

Figurt 5.4. VCPW-VSR CNdt Plaot (250MVA VSR ShNwn)