IOM 53 3/4-4 10/2013

REV B.

Page 3 of 6

Eaton Hydraulics LLC, Filtration Division, 44 Apple Street, Tinton Falls, NJ 07724, www.filtration.eaton.com, Phone732-212-4700

Model 53BTX Duplex Strainer

, Sizes ¾” – 4”

INSTALLATION (

CONTINUED

)

Eaton recommends that basket well drain plugs be removed

and pressure equalizer valves with a drain valve be installed

(standard on 4” size) see Figure 1.

Figure 1

Eaton also recommends replacing each cover plug with a vent

valve and piping to a safe area. See Figure 2.

Figure 2

Pressure gauges near the strainer inlet and outlet are required

to determine differential pressure across the strainer and

cleaning frequency. Pressure gauges are essential for the safe

operation of the strainer.

CAUTION:

To protect the operator during

draining and venting, the fluid must be piped

to a safe area. This requirement is for all fluids

and water with temperatures above 120° F.

The operator should wear appropriate protective equipment

(goggles, gloves, vests, clothing etc.) consistent with the

process fluid for strainer operation and servicing.

START UP

1.

Open cover vent valves and cartridge vent. Close pressure

equalizer valves and drain valve. Rotate the handle 90º

clockwise, so that the handle is over the strainer inlet.

2.

Slowly

allow fluid to enter the strainer. First,

slowly

open

the downstream valve nearest to strainer outlet. Then

slowly

open the upstream valve nearest to the strainer

inlet.

3.

Close cover vent valves and cartridge vent when air is

expelled. Rotate the handle 90º counterclockwise over the

right side basket well. See Figure 3.

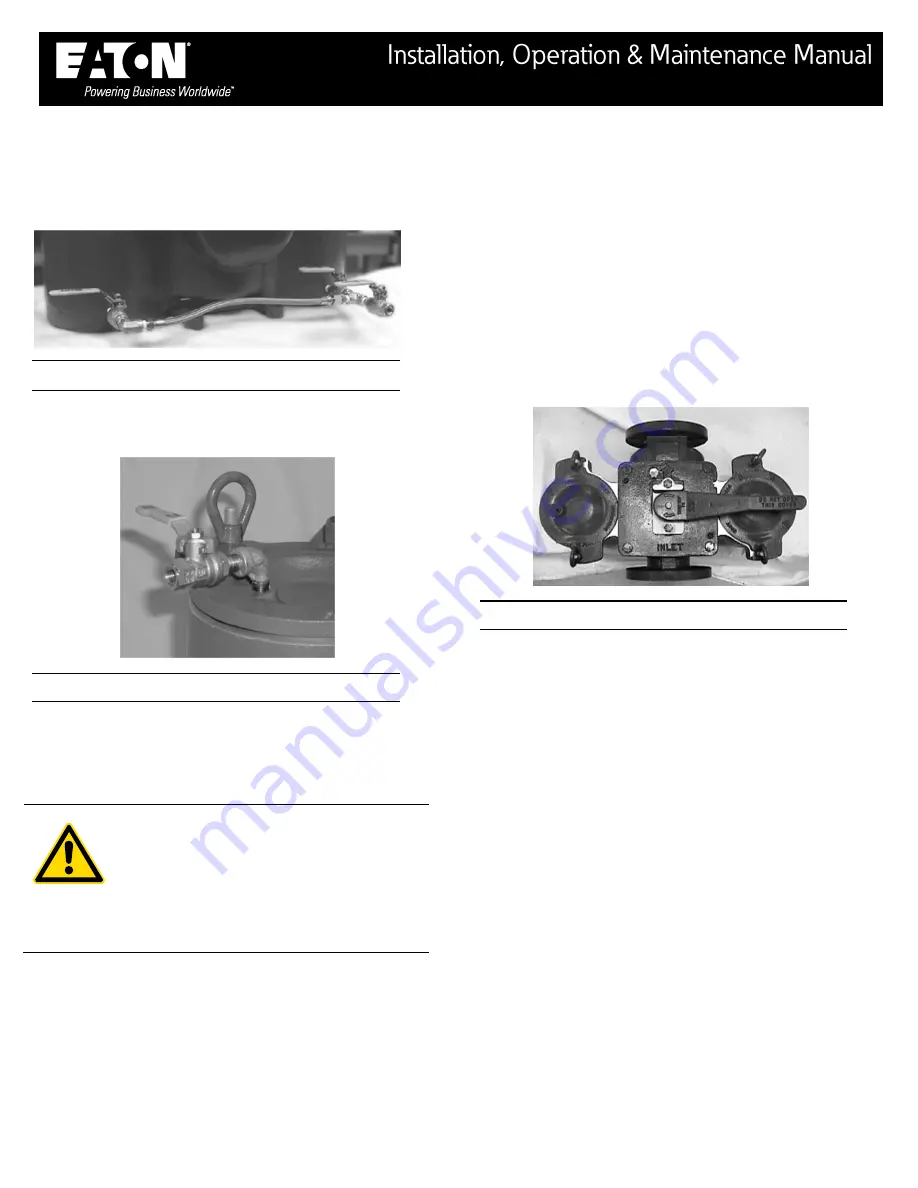

Figure 3

OPERATION

The strainer handle’s position indicates which basket well is in

operation. The handle in the 3 o’clock position over the cover

indicates the right basket operation. This

prevents

access to

the basket underneath the handle. See Figure 3. The handle in

the 9 o’clock position indicates the left basket operation

Note:

Above references are with the strainer inlet in the 6 o’clock

position.

SWITCHING FLOW

Open both pressure equalizer valve to insure that both basket

wells are pressurized and rotate the strainer handle 180°

(traveling over the strainer inlet) until the handle is over the

opposite basket cover from where the handle started. Close

both pressure equalizer valves.