IOM 570 06/2011

REV A.

Page 3 of 8

E

aton Hydraulics LLC, Filtration Division, 44 Apple Street, Tinton Falls, NJ 07724, www.eaton.com/filtration, Phone 732-212-4700

Installation, Operation & Maintenance Manual

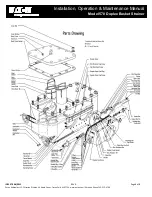

Model 570 Duplex Basket Strainer

OPERATION

1.

Determine the location of the valve disc, or “gate,” by

observing the operation spindle through the sight holes at

the end of the spindle mountings (see drawing page 6).

The stainless steel operating spindle (1-1/2” diameter) can

be seen through the sight hole on the isolated side. The

torque bar (15/16” diameter) and/or the operating screw

(acme threaded) can be seen through the sight hole on the

operating side.

START

UP

1.

Open both chamber vents. Rotate hand wheels a

minimum of 20 turns to locate valve discs such that both

chambers start to fill.

2.

Close vents when chambers are filled and rotate hand

wheels in the same direction until stop is reached. This

way, only half the baskets are in service.

3.

Close pressure equalizer valve.

4.

Slowly introduce fluid to be strained.

CAUTION:

Start system GRADUALLY. This

eliminates sudden shock to strainer and other

equipment in the line.

CAUTION:

Recheck “Operation” procedure to

ensure that both valve discs are sealing the same

chamber. There should be NO SIGNIFICANT

AMOUNT OF FLOW from vent in chamber that is

isolated.

NOTE:

The valve discs or “gates” are not designed

or intended to provide absolute tight shut-off.

Manufacturing standards require valve seepage to

be low enough to provide time for basket exchange

only.

SHUTDOWN:

TEMPORARY

1.

Tightly close valves on inlet and outlet connections of the

strainer.

2.

Open vents to relieve liquid pressure in the strainer.

CAUTION:

DO NOT loosen covers while there is

significant liquid or airflow from the vent.

SHUTDOWN:

EXTENDED

PERIOD

If the system is to be shutdown for an extended period:

1.

Drain fluid from the strainer.

2.

Clean the baskets.

3.

Lubricate operating mechanism, the chain drive and, if so

equipped, the cover lift according to directions in section on

lubrication.

4.

Unseat the valve discs by turning hand wheels 15 to 20

turns.

5.

Open pressure equalizer valve.