600 A 15/25 kV Class T-OP II connector assembly installation instructions

4

INSTALLATION INSTRUCTIONS

MN650048EN May 2017

●

●

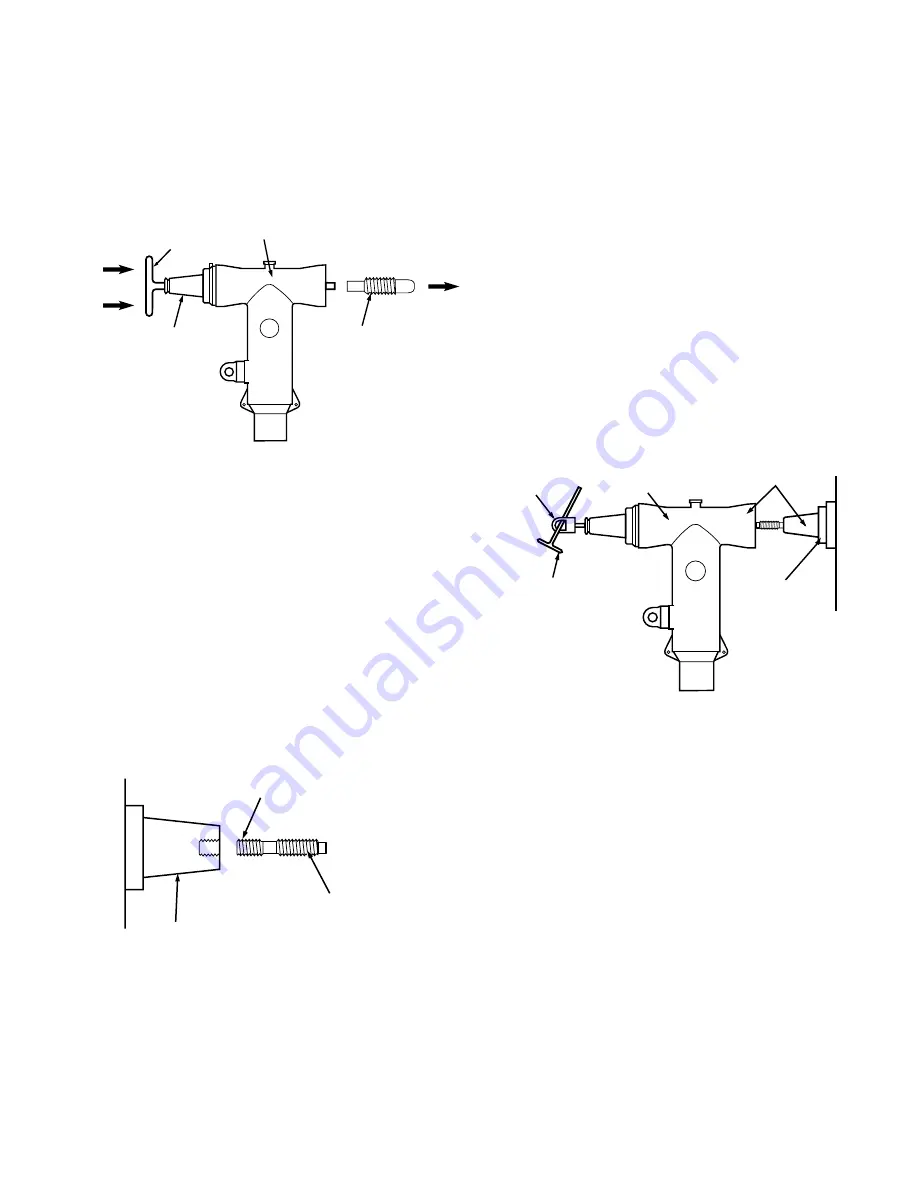

Remove alignment segment by applying pressure to the

T-Wrench to separate the alignment segment from the

LRTP. Recycle the align ment segment.

●

●

See Figure 9 for illustration of completed

LRTP installation.

LRTP

T-OP II ASSEMBLY

T-WRENCH

SEPARATED

ALIGNMENT

SEGMENT

Figure 9 . LRTP permanently installed into T-body

forming the T-OP II assembly

Install T-OP II assembly onto apparatus bushing

Step 8

Install stud into apparatus bushing

●

●

Ensure unit is de-energized.

●

●

Thread the shorter threaded end of the T-OP II stud

into the apparatus bushing until hand tight. (Refer to

Figure 10).

●

●

Engage the flats on the stud with a 1/2” wrench and

thread the stud into the bushing an additional 1/4

revolution past hand tight.

●

●

Remove any shavings that may have been raised during

the threading procedure.

APPARATUS BUSHING

SHORT THREADS

INTO BUSHING

EXTENDED

STUD (STUD-T)

Figure 10 . Line illustration of bushing stud installation

Step 9

Install the T-OP II assembly on the apparatus bushing

●

●

Clean and lubricate mating interfaces of the apparatus

bushing and T-body with the lubricant supplied.

●

●

Push the T-OP II assembly onto the apparatus bushing

until the extended length stud makes contact with the

rotating nut in the LRTP.

●

●

Insert the 5/16” torque tool into the 200 A tap and

engage the rotating nut. (Refer to Figure 11.)

●

●

Place a screwdriver or the T-wrench through the hotstick

operating eye of the torque tool (live-line tools can be

used to operate the T-OP II when de-energized) and

tighten the T-OP II assembly until the tool ratchets.

(20-25 ft.-lbs.)

ote:

N

If 5/16” hex rod (HD625) is used with customer

supplied torque wrench, thighten to 20-25 ft.-lbs.

●

●

Remove torque tool.

600 A

INTERFACES

APPARATUS

BUSHING

TQHD625

TORQUE TOOL

T-WRENCH

T-OP II

ASSEMBLY

Figure 11 . Installing the T-OP II assembly onto the

apparatus bushing

Step 10

Cap the 200 a interface

●

●

Clean and lubricate 200 A interface of LRTP and mating

apparatus (i.e., protective cap, grounding elbow, M.O.V.E.

arrester) with lubricant supplied. (Refer to Figure 12.)

●

●

To cap interface, follow installation instructions supplied

with the separable insulated connector used.