16

Model 70360

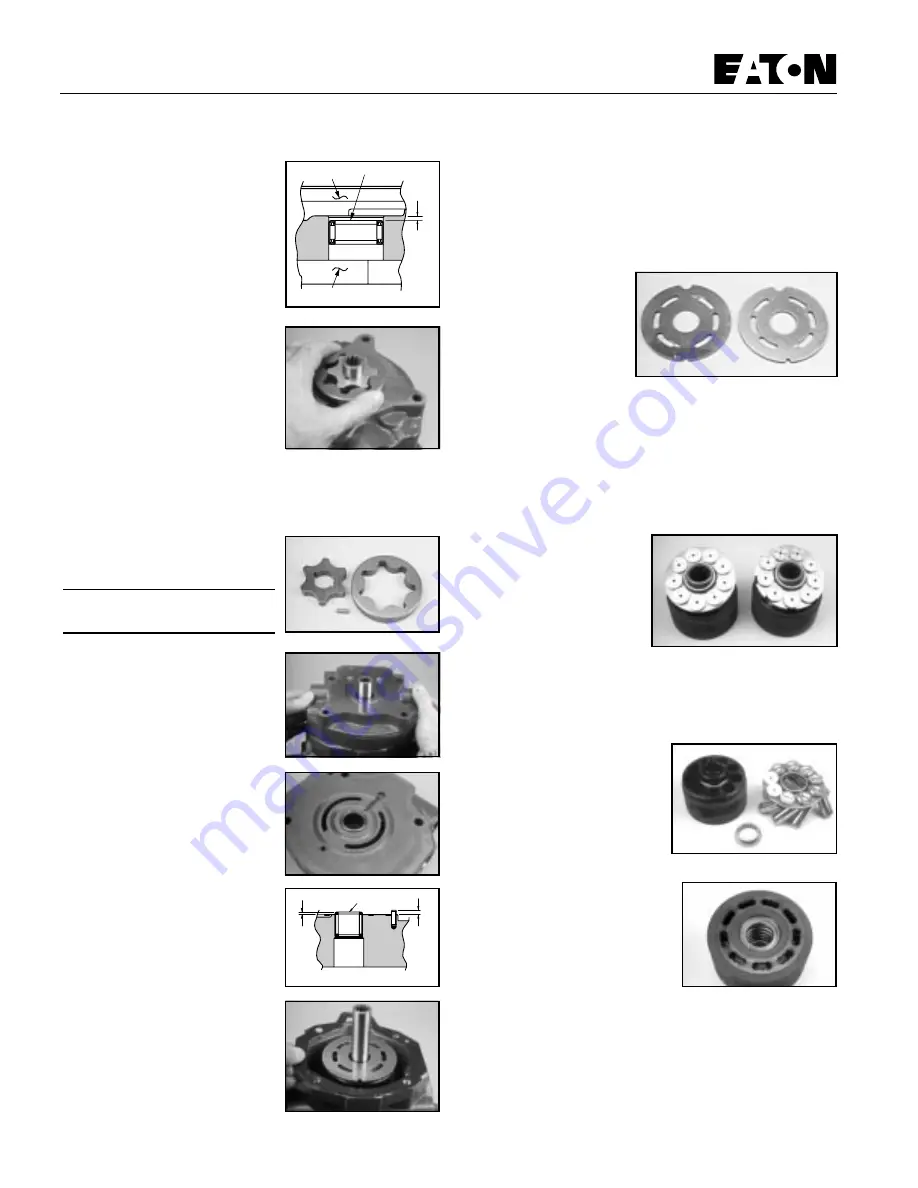

13 When the needle bearing

assembly is replaced, the

numbered end of the bearing must

face toward the flange side of the

adapter to the dimension as

shown. (See Figure 13)

14 With the charge pump adapter

removed, remove the charge pump

assemblies outer and inner gerotor

ring. Next, remove the small drive

key from the pump shaft. (See

Figure 14 and 15)

15 Charge pumps are available in

two different displacements Charge

pump displacements are based on

the thickness of the gerotor

assembly and the depth of the pocket located in the charge

pump adapter. To determine the displacement, refer to the

table below.

Gerotor Pocket Depth

Displacement

Depth of Pocket

cm

3

/r [in

3

/r]

mm [in.]

6.9 [.42]

6.35 [.25]

13.8 [.84]

12.7 [.50]

16 To separate the backplate

assembly from the dowel pins in

the pump housing assembly, insert

two screwdrivers between

backplate and housing assembly

and pry upward. (See Figure 16)

17 After separation, remove the

backplate from the housing

assembly.

18 Turn the backplate assembly

over and inspect the needle

bearing. The needles in the needle

bearing must remain intact in the

bearing cage. (See Figure 17)

19 When the needle bearing

assembly is replaced, the

numbered end of the bearing must

face the valve plate side of the

backplate to the dimension as

shown. (See Figure 18)

20 With the backplate removed,

remove the gasket from the pump

housing assembly and discard.

(See Figure 19)

21 Remove the valve plate from the piston block assembly.

Note: This valve plate may have stuck to the backplate

assembly that was just previously removed.

22 Valveplate directional rotation (CW or CCW) is identified

by the location of the metering slots located on the face of the

valve plates. Pump input

rotation should always turn

into the metering slots.

(See Figure 20) A clockwise

valve plate is shown on the

left and a counter clockwise

valveplate is on the right.

Note: Whenever pump input rotation is changed, the valve

plate must be replaced along with the desired rotation charge

pump adapter.

23 Remove the rotating kit assembly by carefully retaining it

in the housing assembly. Lift the housing and rotating kit

assembly and turn over assemblies allowing the rotating kit

assembly to slide down the input shaft and out of the pump

housing.

24 The model 70360 variable

displacement pumps are

available in two different

displacements. The 40,6 cm

8

/r

~ [2.48 in

3

/r] rotating kit

assembly is shown below on

the left. The 49,2 cm

3

/r [3.00 in

3

/r] rotating kit assembly is

shown below on the right. The 49,2 cm

3

lr [3 00 in

3

/r] rotating

assembly is easily identified by having larger pistons and

cutouts in the spider. (See Figure 21)

25 With the rotating kit

assembly removed, remove the

piston assemblies, spider and

spider pivot from the piston

barrel. (See Figure 22)

26 Inspect the piston

assemblies, spider, spider pivot

and piston block. The piston block

assembly usually requires no

further disassembly unless the pins

or block spring are damaged.

27 When any excessive wear or

scratches are noted on the face of

the piston block, the block

assembly must be replaced. (See Figure 23)

DO NOT LAP THE FACE OF PISTON BLOCK ASSEMBLY.

Numbered End

Gerotor Pocket

2.41 mm

[.095 in.]

Flange

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

2.79 mm

[.110 in.]

1.91 mm

[.075 in.]

Numbered End

Figure 18

Figure 19

Figure 20

Figure 21

Figure 22

Figure 23

Repair Information