14

Model 72400

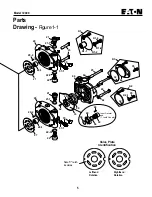

48-18

48-19-1

48-19-2

48-19

48-20

48-21

48-28

48-30

48-29

48-27

48-22

48-23

48-24

48-25

48-26

48-19-2A

48-19-2B

48-19-2C

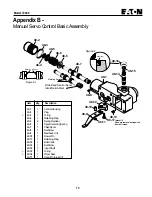

Appendix B -

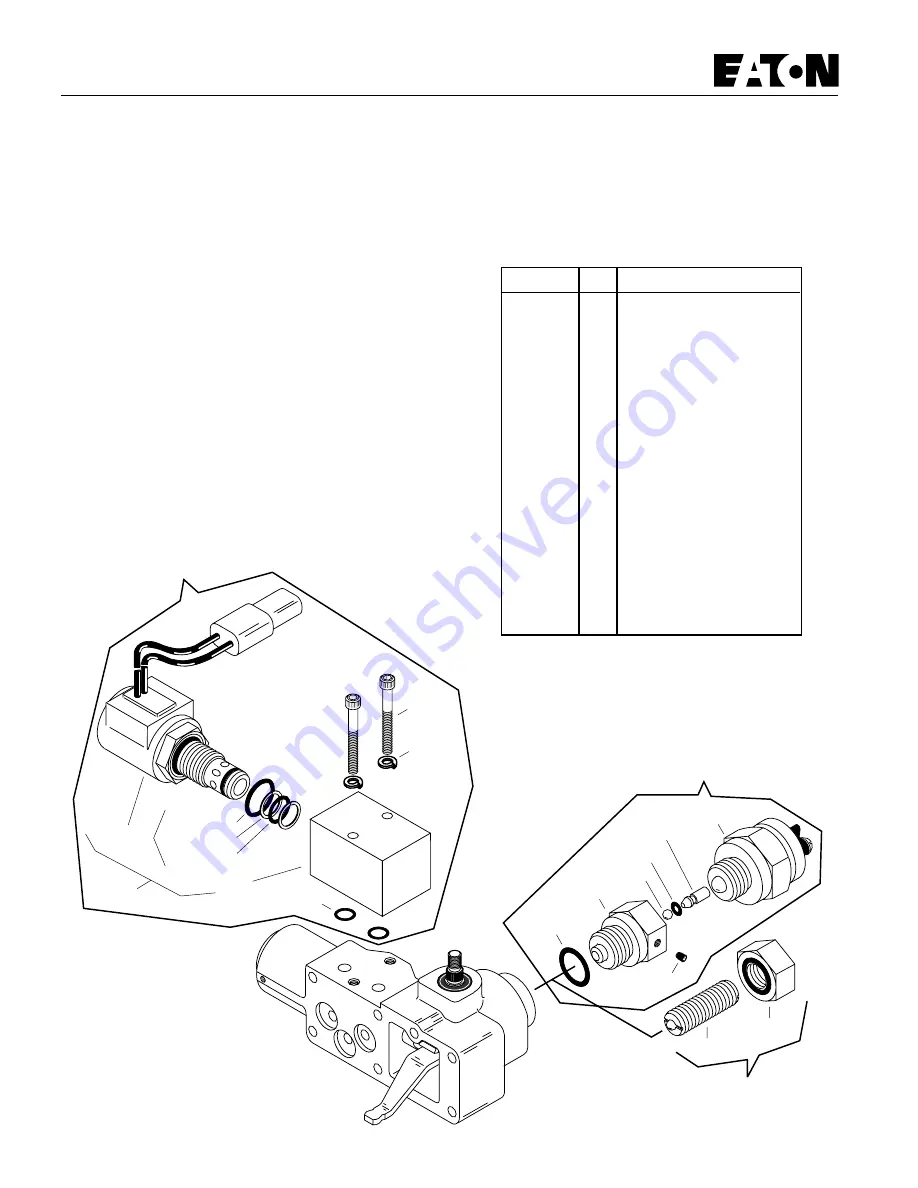

Manual Servo Control Assembly Options

Disassembly -

Destroke Valve Assembly Option

1

Remove the two cap screws and lock washers from

manifold. Removing destroke valve assembly and two o-rings.

2

Remove destroke valve from manifold in order to remove

o-rings and back-up washers. Note: in order to remove

destroke valve the solenoid may need to be removed from core

first (not shown).

Reassembly -

Destroke Valve Assembly Option

1

Install new o-rings and back-up washers onto destroke

valve.

2

Install destroke valve into manifold by hand until top o-ring

is met by manifold. Then wrench tighten to 34 N•m [25 lbf•ft. ]

max. Loosen Nut retaining coil to reposition if necessary and

re-torque 5,4 to 7 N•m [4 to 5 lbf•ft.].

3

Lubricate the two o-rings and install onto manifold. Install

destroke valve assembly onto control assembly. Retain with

lock washers and cap screws. Torque 3 to 3,5 N•m [27 to 31

lbf•in.].

Destroke Valve

Assembly

Option

Neutral Detent

Option

Neutral Lockout

Switch Option

Item

Qty.

Description

48-18

2

O-ring

48-19

1

Destroke Valve Assy.

48-19-1

1

Manifold

48-19-2

1

Destroke Valve

48-19-2A

1

O-ring

48-19-2B

2

Back-up Washer

48-19-2C

1

O-ring

48-20

2

Lock Washer

48-21

2

Cap Screw

48-22

1

O-ring

48-23

1

Adapter, Neutral Lockout

48-24

1

Ball

48-25

1

O-ring

48-26

1

Pin

48-27

1

Set Screw

48-28

1

Neutral Lockout Switch

48-29

1

Ball Plunger

48-30

1

Nut, Seal