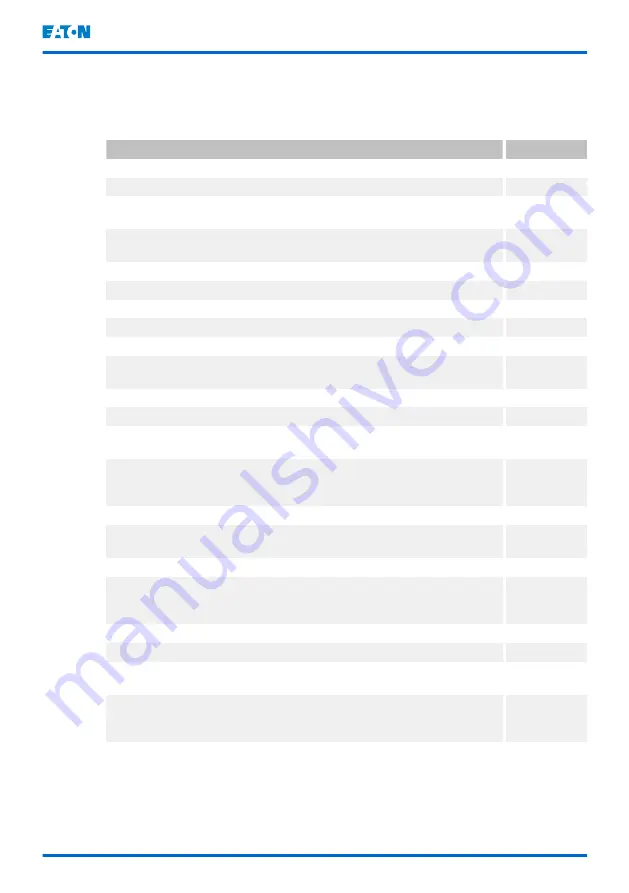

4.2 Installation checklist

Table 4: Single unit installation checklist

Action

Yes / No

All packing materials and restraints are removed from each cabinet.

The UPS cabinet is placed in its installed location.

A readily accessible disconnect device is installed between the UPS in-

put and utility power, in the immediate vicinity of the UPS.

All conduits and cables are properly routed to the UPS and any ancillary

cabinets.

All power cables are properly sized and terminated.

Neutral conductors are installed.

Battery connection polarity is correct.

Ground conductors are properly installed.

(OPTIONAL) Signal inputs are wired appropriately.

(OPTIONAL) OVT output and feedback inputs are correctly installed in

external battery breaker.

(OPTIONAL) LAN drops are installed.

(OPTIONAL) LAN connections have been completed.

(OPTIONAL) The remote EPO device is mounted in its installed location

and its wiring is terminated inside the UPS cabinet.

(OPTIONAL) A jumper wire is connected between pins 3 and 4 on the

remote EPO terminal block if using a normally-closed remote EPO

switch.

All terminal cover plates are installed.

(OPTIONAL) Accessories are mounted in installed locations and wiring

is terminated inside the UPS cabinet.

Air conditioning equipment is installed and operating correctly.

The area around the installed UPS system is clean and dust-free. (Eaton

recommends that the UPS be installed on a level floor suitable for com-

puter or electronic equipment.)

Adequate workspace exists around the UPS and other cabinets.

Adequate lighting is provided around all UPS equipment.

A 230 Vac service outlet is located within 7.5 metres (25 feet) of the UPS

equipment.

Startup and operational checks are performed by an authorized Eaton

Customer Service Engineer or by a service engineer from an agent au-

thorized by the manufacturer.

Eaton 93E Generation 2 UPS 100-200 kVA

(380/400/415V)

User's and installation guide

©

Eaton Corporation plc 2019. All rights reserved.

Revision: 002

Document ID: P-164000848

32 (118)