41

6.5.1. Connection to I/O unit

Each I/O unit also has a BI/O bus. The light I/O units (ARC-EP10-2/2.0, ARC-EP10/2.0

ARC-EL3/2.0) can transmit trip information to the master unit or current I/O unit. The current

I/O unit (ARC-EC1/2.0) can receive the light information and send the current information to

other I/O units.

The following DI and DO connections are included in the standard delivery of ARC-

EP10/2.0 and ARC-EL3/2.0 units:

DI

X2-8

Zone

shift

1

2, 2

1, 3

4, 4

3

GND

X2-7

Trip out

X2-10

Trip information, 24 V dc

GND

X2-9

Trip

information

earth

The following DI and DO connections are included in the standard delivery of ARC-

EC1/2.0 units:

L>in

X2-8

Light input, 24-48 V dc

GND

X2-7

Light

input

earth

Trip out

X2-10

Trip information

GND

X2-9

Trip

information

earth

6.5.2. Connection to quenching device ARC-AT

The master unit ARC-EM/2.0 can be connected to an ARCON quenching device ARC-AT.

In the event of an arc fault the master unit generates a tripping pulse for the quenching de-

vice. The quenching device generates within 1ms a permanent 3-pole metallic short circuit.

Therefore the arc voltage subsides and the arc fault extinguishes.

After an arc fault switch-off the quenching device has to be replaced.

Figure: ARCON quenching device ARC-AT-B (schematic drawing)

(1) LED (green) displays operating mode

(2) LED (red) displays arc fault switch-off mode

(3)

Fixing

brackets

(4)

Busbar

connection

(5) Connection to master unit ARC-EM/2.0 (via connection cable ARC-CCAT)

(6)

Nameplate

ARCON

①

③

⑤

④

⑥

②

ARC-AT

Summary of Contents for ARCON 2.0 Series

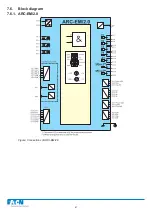

Page 51: ...51 7 6 Block diagram 7 6 1 ARC EM 2 0 Figure Connections of ARC EM 2 0...

Page 54: ...54 7 6 4 ARC EL3 2 0 7 6 5 ARC EC1 2 0...

Page 64: ...64 9 Construction 9 1 Dimensional drawings 9 1 1 ARC EM 2 0 panel and semi flush mounting...

Page 65: ...65 9 1 2 ARC EP10 2 2 0 din rail mounting...

Page 66: ...9 1 3 ARC EP10 2 0 din rail mounting 66...

Page 67: ...67 9 1 4 ARC EL3 2 0 din rail mounting...

Page 68: ...68 9 1 5 ARC EC1 2 0 din rail mounting...

Page 69: ...69 9 1 6 Fiber sensor mounting r min 50 mm...

Page 70: ...70 9 1 7 Point sensor mounting...

Page 82: ...82 10 Application examples 10 1 Applications 10 1 1 With a main busbar system...

Page 83: ...83 10 1 2 With two main busbar systems...

Page 84: ...84 10 1 3 With two main busbar systems and additional zone selection 4 zones...

Page 85: ...85...