10

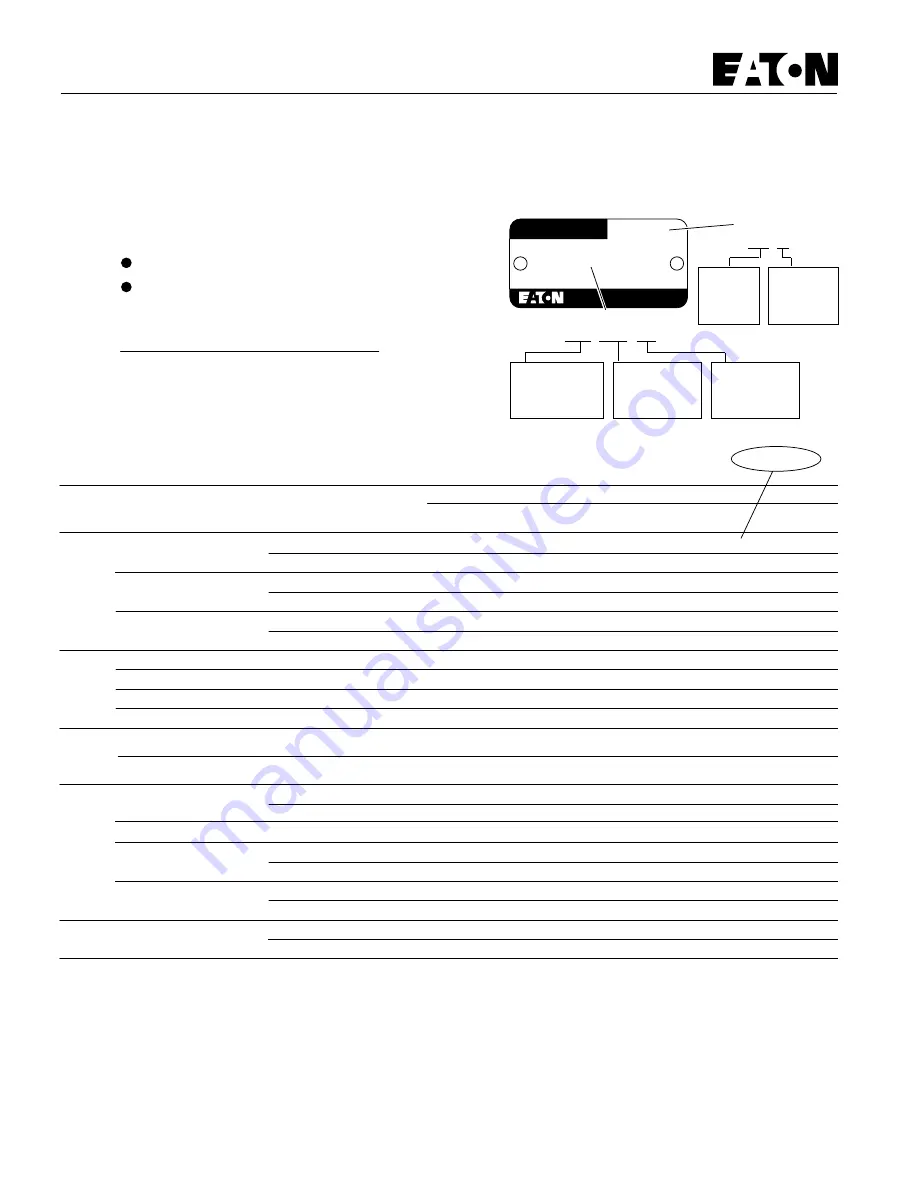

2000 Series Disc Valve Motors

104-1007

104-1001

-1002

-1003

-1004

-1005

-1006

-1007

-1143

1 inch Straight

2 Bolt

SAE A

Flange

Displacement cm

3

/r [ in

3

/r ] and Product Number

Shaft

Mounting

100

[ 6.2]

130

[ 8.0]

160

[ 9.6]

195

[11.9]

245

[14.9]

305

[18.7]

395

[24.0]

80

[ 4.9]

490

[29.8]

104-1037

-1038

-1039

-1040

-1041

-1042

-1043

-1044

7/8-14 O-ring Staggered

Ports

1-1/16—12 O-ring 180

°

Apart

104-1022

-1023

-1024

-1025

-1026

-1027

-1028

-1228

-1420

1-1/4 Inch Straight

104-1061

-1062

-1063

-1064

-1065

-1066

-1067

-1068

-1421

7/8-14 O-ring Staggered

1-1/16—12 O-ring 180

°

Apart

104-1029

-1030

-1031

-1032

-1033

-1034

-1035

-1229

-1422

1-1/4 Inch

14 T Splined

104-1087

-1088

-1089

-1090

-1091

-1092

-1093

-1094

-1423

7/8-14 O-ring Staggered

1-1/16—12 O-ring 180

°

Apart

32 mm Straight

104-1384

-1385

-1386

-1387

-1388

-1389

-1390

-1391

G 1/2 (BSP)

105-1001

-1002

-1003

-1004

-1005

-1006

-1007

-1060

104-1376

-1377

-1378

-1379

-1380

-1381

-1382

-1383

G 1/2 (BSP)

1-1/4 Inch

14 T Splined

105-1071

-1072

-1073

-1074

-1075

-1076

-1077

-1078

Standard

with 4 Bolt

Square

Flange

105-1029

-1030

-1031

-1032

-1033

-1034

-1035

-1096

105-1079

-1080

-1081

-1082

-1083

-1084

-1085

-1086

7/8-14 O-ring Staggered

1-1/16—12 O-ring 180

°

Apart

7/8-14 O-ring Staggered

1-1/16—12 O-ring 180

°

Apart

Wheel

Motor

105-1134

-1135

-1136

-1137

-1138

-1139

-1140

-1141

G 1/2 (BSP)

32 mm Straight

1-1/4 Inch

14 T Splined

1-1/4 Inch

Tapered

106-1008

-1009

-1010

-1011

-1012

-1013

-1014

-1015

-1047

106-1038

-1039

-1040

-1041

-1042

-1043

-1044

-1045

G 1/2 (BSP)

7/8-14 O-ring Staggered

Bearingless

2 Bolt

SAE B

Flange

104-1200

-1201

-1202

-1203

-1204

-1205

-1206

-1207

1-1/4 Inch Straight

104-1208

-1209

-1210

-1211

-1212

-1213

-1214

-1215

7/8-14 O-ring Staggered

104-1193

-1194

-1195

-1196

-1197

-1198

-1199

104-1216

-1217

-1218

-1219

-1220

7/8-14 O-ring Staggered

7/8-14 O-ring Staggered

7/8-14 O-ring Staggered

1-1/4 In. Involute SAE C Splined

1 Inch SAE 6B Splined

7/8 Inch SAE B Splined

7/8-14 O-ring Staggered

1-1/16—12 O-ring 180

°

Apart

1-1/4 Inch Straight

—

—

—

—

—

—

—

—

—

—

—

—

—

—

-1148

-1149

-1152

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

105-

105-

—

—

Use digit prefix —104-, 105-, or 106- plus four digit number from charts

for complete product number—Example 106-1039.

Product Numbers—2000 Series

Each Order Must Include the Following:

How to Order Replacement Parts

1. Product Number

2. Date Code

3. Part Name

4. Part Number

5. Quantity of Parts

For Additional Literature Contact Eaton Corp. Hydraulics

Division 15151 Highway 5 Eden Prairie, MN 55344.

Specifications and performance data, Catalog No. 11-878

Replacement part numbers and kit information — Parts

Information No. 6-129

Char-Lynn

®

Product number

Eaton Corp.

Hydraulics Div.

Eden Prairie, MN 55344

Product Number

000 0000 000

Product Line

Identification

Number

Product

Identification

Number

Engineering

Change

Code

Week of

Year 01

Thru 52

Last

Number(s)

of Year

Date Code

00 00

Product Identification