8

EATON Char-Lynn

Delta Motors Parts and Repair Manual C-MOLO-TS003-E September 2007

Reassembly

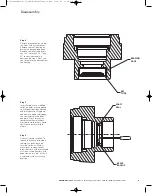

Step 6

Install the second backup ring

into the housing. Invert the

balance ring and place into the

housing making sure to align

the dowel pins with the holes

in the housing.

Important Note:

Press on the

balance ring and verify that it

springs back when released.

This ensures that the ring has

not been pinched.

Step 7

Install the valve into the housing

with the shaft notch lining up

with the longest tang of the

valve. Insert button end of the

drive into the shaft and mark

the spline tooth that lines up

with the notch in the shaft. This

marked tooth is critical in the

timing of the motor.

X

Y

Z

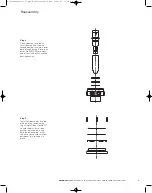

Step 8

Insert the thrust bushing in the

valve plate aligning its tabs.

Press bearing into valve plate

with Tool No. 606252 with the

lettering on the bearing contacting

the tool. Place valve plate

assembly into the housing

aligning the bolt holes.

DeltaPartManual_v7.qxd:HydraulicsTech.qxd 9/19/07 11:40 AM Page 8