9

EATON Char-Lynn

Delta Motors Parts and Repair Manual C-MOLO-TS003-E September 2007

Reassembly

CW

CW

CCW

CCW

B

A

B

A

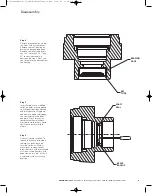

Step 9

Install two greased seals into

the Geroler

®

. Install the

Geroler

®

onto the drive with

splined end away from the

housing. Align star according to

rotation preference as outlined

in the timing procedure. Timing

procedure is given below.

a. Standard Timing

Align the marked spline of the

drive with star tip. This pro-

duces CCW rotation when the

A port is pressurized.

b. Reverse Timing

Align the marked spline of the

drive with star valley. This pro-

duces CW rotation when the A

port is pressurized.

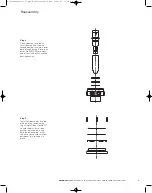

Hex Head

Screw

End Cap

Gerolor

Assembly

O-ring

O-ring

Timing

Mark

Timing

Mark

Standard Timing

Reverse Timing

Step 10

Place the end cap on the

Geroler

®

and align the bolt

holes. Lubricate and insert

seven bolts and torque them to

500±50 lbf-in (42±4 lbf-ft, 56±5

Nm) in a crisscross pattern.

DeltaPartManual_v7.qxd:HydraulicsTech.qxd 9/19/07 11:40 AM Page 9