CAUTION

Bushing damage . The split aluminum ring must be

replaced if damaged . The clamping ring cushions and

distributes the pressure between the bushing flange and

the bushing . If bushing clamps are assembled without a

new clamping ring, the bushing may be damaged when

clamp hardware is tightened .

T234 .1

4. Install new bushing assembly. Position a new bushing

gasket between bushing flange and head casting.

5. Position aluminum clamping ring, so split will be

centered between two clamping bolts.

6. Replace bushing clamps and tighten cap screws evenly,

a little at a time, to 6-10 lbs-ft (8-13 Nm).

CAUTION

Dielectric failure, bushing damage . To prevent gasket

leaks or bushing damage, clamping force must be

applied gradually and equally in rotation to each bolt .

If the clamping force is not evenly applied, seal leakage

can result, compromising the dielectric capabilities of the

recloser and can cause possible personal injury . Unequal

clamping force can cause bushing breakage .

T235 .2

7. Reconnect bushing lead and tank recloser.

Bushing porcelain replacement, recloser tanked,

Type V4L only

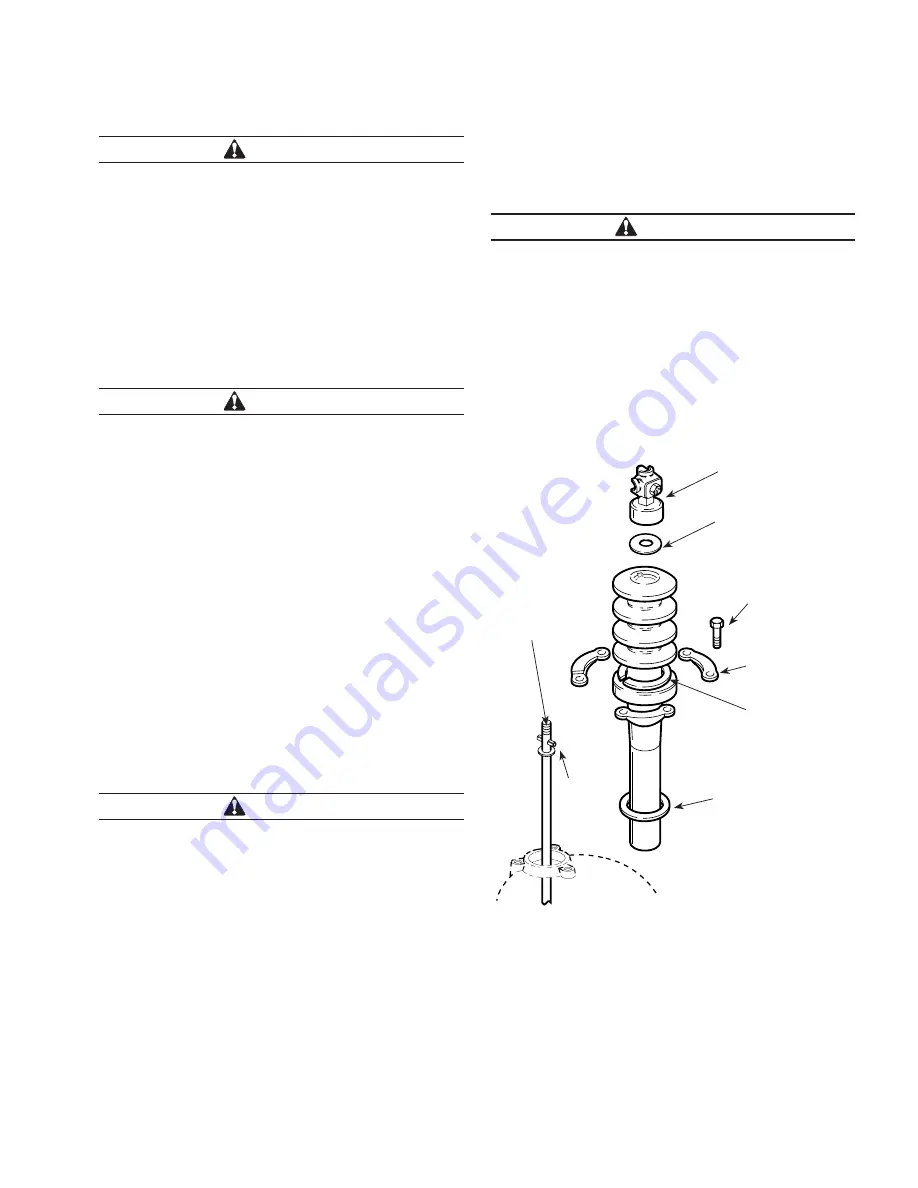

1. Unscrew bushing terminal, discard terminal gasket,

see Figure 3.

2. Remove three hex-head cap screws and bushing

clamps that secure bushing porcelain to head

casting. Lift bushing porcelain from head, discard

bushing gasket.

3. Twist aluminum clamping ring and remove from

old bushing porcelain. If ring is in good condition,

it may be reused. If ring is damaged it must

be replaced.

CAUTION

Bushing damage . The split aluminum ring must be

replaced if damaged . The clamping ring cushions and

distributes the pressure between the bushing flange and

the bushing . If bushing clamps are assembled without a

new clamping ring, the bushing may be damaged when

clamp hardware is tightened .

T234 .1

4. Install new bushing porcelain. Position a new

bushing gasket between bushing flange and head

casting. Turn porcelain until locking key (roll pin

through bushing lead) is properly seated.

5. Position aluminum clamping ring, so split will be

centered between two clamping bolts.

6. Replace bushing clamps and tighten cap screws

evenly, a little at a time, to 6-10 lbs-ft (8-13 Nm).

CAUTION

Dielectric failure, bushing damage . To prevent gasket

leaks or bushing damage, clamping force must be

applied gradually and equally in rotation to each bolt .

If the clamping force is not evenly applied, seal leakage

can result, compromising the dielectric capabilities of the

recloser and can cause possible personal injury . Unequal

clamping force can cause bushing breakage .

T235 .2

7. Install new terminal gasket.

8. Apply a very small amount of petroleum jelly to

the knurled inside surface of the bushing terminal.

Screw terminal onto lead and tighten to 20-25 lbs-ft

(27-34 Nm).

Lower bushing

gasket

Bushing clamps

Locking

key

Bushing

rod

Split aluminum ring

Hex head

capscrews

Bushing gasket

Bushing terminal

Figure 3 . Bushing porcelain replacement

Types V4L and V4E single-phase maintenance instructions

7

MAINTENANCE INSTRUCTIONS

MN280055EN May 2017