12

6.2 Opening the device /

Electrical connection

Before opening flameproof enclosures with

or without switches, it is necessary to ensure

that there is no voltage or to take suitable

protective measures.

The connection of explosion-protected

flameproof enclosures and distributions may

only be carried out by specialists.

If flameproof apparatus without connection or bus

bar boxes in the type of protection ”Increased

Safety” are to be connected, this flameproof

apparatus is connected directly in the flameproof

enclosure using certified flameproof cable entries,

whereby the mounting instructions for the cable

entry shall be taken into account (see Section

6.3.2 Cable Entries).

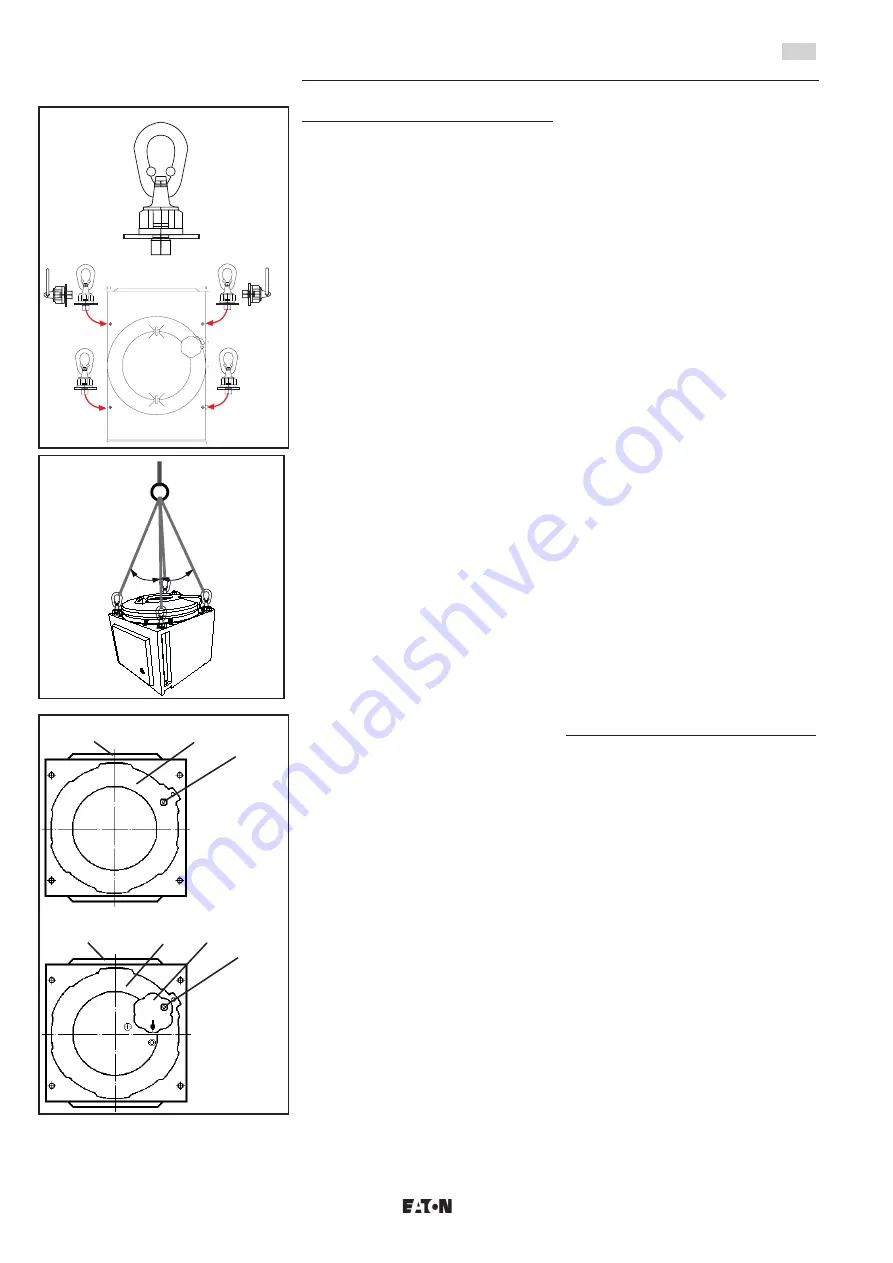

Fig. 3

1

2

3

Fig. 4

1

2

4

3

6.1 Mounting

The flameproof enclosure can lift with a minimum

of two swivel eye bolts.

They can fix at the fixing points as shown in Fig. 1,

Fig. 2 and dimension drawings. The swivel eye

bolts have to be suitable for this use and for the

weight of the flameproof enclosure.

The swivel eye bolts chosen shall fit the fixing

points

Ø 14 for enclosures sizes 1, 2, 4, 5 and 7

Ø 23 for enclosures size 6.

Use big size washers to protect the flameproof

enclose against damage. Especially if the

flameproof enclosure are use for wall mounting

and the swivel eye bolts have to angled square.

Use nuts to fix the swivel eye bolts. Observe the

instruction of the swivel eye bolts.

In addition to the notes of the manufacturer, the

relevant national regulations and guidelines for

lifting loads have to be observed.

When the flameproof enclosures and

distributions are mounted directly onto the

wall or onto wall or floor frames, they shall

rest evenly only on the fastening points

provided for this purpose.

In order to be able to open the covers of

flameproof enclosures faultlessly, it is

absolutely essential to ensure that the

flameproof enclosures are assembled without

twisting (see technical data for test torques).

Fixing dimensions are shown in the dimension

drawings on pages 9 and 10.

The screws chosen shall fit the fixing hole

M12 for enclosures sizes 1,2,4,5 and 7

M20 for enclosures size 6

and shall not damage the hole (e.g. use of a

washer).

The number of screws used for fixing the

apparatus shall correspond to the number of fixing

holes in the enclosures.

In the event of distributions with several

enclosures in the same size, the covers of the

flameproof enclosures shall not be inter-

changed.

Which flameproof enclosure cover belongs to

which enclosure base can be determined by

identical production numbers on the inside of the

enclosure cover and the front of the enclosure

base.

If distributions that are mounted on a wall or floor

frame are to be divided for transport purposes or

because the maximum distribution length has

been exceeded, the parts of the distribution shall

be reassembled as follows:

Explosion-protected flameproof enclosures and distributions,

series: GHG 6.. and EXKO

1. Place the system units next to each other in

such a way that the fixing points of the bus

bar boxes and the fixing points of the frame

coincide.

2. All the seals between bus bar boxes and/or

also connection boxes shall be inserted

correctly. The parts can then be screwed

together using the screws provided.

3. After this, the electrical connections of the bus

bar systems or the connection terminals of the

connection boxes shall be made correctly at

the points where the system was divided

using the connection pieces provided (copper

rails or wire connectors), whereby the

connections shall be tightened down securely

(see also Section 6.1 ”Electrical connection”).

Special attention shall be paid to the PE

connections.

Separate documents containing assembly

instructions for units in special designs are

provided with the installation.

Warning: Immediately after installation or

erection, distributions on floor frames shall

be safeguarded against falling over.

If necessary, individual system units with a

maximum length of 6.00 m can be built and joined

together at given points to form a distribution

installation.

Warning: The unit assembled via the bus bar

systems shall not exceed the overall length of

6.00 m.

435

430

329

155,5

X

365

14

975

X 405

311

Fig. 1

Fig. 2

< 45°

< 45°

GB