10

6 Installation

For the mounting and operation, the

respective national regulations as well as

the general rules of engineering shall be

observed (IEC/EN 60079-14).

X

ATEX - IEC

When mounting the separately certified

terminals, the clearance an creepage distance

must be observed in accordance to table 1 of

IEC/EN 60079-7.

6.1 Mounting

The plastic boxes can be mounted without

opening their enclosure.

When mounting the terminal boxes directly

onto the wall, they shall rest evenly only on the

fastening points provided for them. The chosen

screw must match the fastening hole (see

dimensional drawings page 8) and they shall

not damage the hole (e.g. use of a washer).

The terminal boxes must be fastened diagonally

by means of at least 2 screws.

If the screws are overtightened, the

plastic terminal boxes may be damaged.

The plastic terminal boxes GHG 721 0 and

GHG 721 0 are suitable for fastening onto CCH/

EATON apparatus holders by means

of self-cutting screws and clip-on mounting

(see fig. 4 - 7, page 11 + 12).

The respective mounting instructions

will have to be observed.

6.2 Opening the apparatus/

Electrical connection

a

The electrical connection of the

apparatus may only be carried out by

skilled staff (IEC/EN 60079-14).

The minimum clearances and creepage

distances in accordance with IEC/EN 60079-7,

Table 1, shall be observed.

The table indicating the current load values

which is provided on the cover inside of the

terminal boxes is to be observed.

In order to maintain the mode of protection, the

conductors will have to be connected with

special care.

The insulation shall reach up to the

terminal. The conductor itself shall not

be damaged.

The connectable min. and max. conductor

cross-sections will have to be observed.

All screws and/or nuts of the supply terminals,

and unused terminals, shall be tightened down.

The fitted standard terminals are designed for

direct connection of conductors with copper

cores.

If stud terminals are fitted, DIN cable lugs shall

be used.

The cable lugs should be crimped onto

the cable in a workmanlike manner. It is to

be ensured that the required min. air gaps

are kept (at 690V ->12mm).

When combining Ex-e/Ex-i it is essential to

maintain the separation, air and creepage

distances. The Ex-i circuit wires are to be laid

separately from the Ex-e circuit wires

(see e.g. EN/IEC 60079-11).

The connection wires of the Ex-i circuits are

to be marked (e.g. by colour, light blue).

After removing the terminal rail (in order to

facilitate the entry of cables), the terminal rail

shall again be properly put in place before

establishing the electrical connection.

Removal and mounting of the terminal rail are

performed as follows:

By pressing apart the enclosure sides, the

terminal rail can be detached from the bottom

part of the enclosure.

In order to install the terminal rail, it is fitted

onto the catch on one side of the enclosure wall

and then snapped in on the opposite enclosure

wall (see fig. 3).

The PE rail can optionally be fitted in 4 positions

(see fig.1):

A Enclosure top side

- PE-connection bottom

B Enclosure top side

- PE-connection top

C Enclosure bottom side - PE-connection bottom

D Enclosure bottom side - PE-connection top

The PE rail is fitted as follows: It has to be

pushed home in the respective guide rails that

are integrated into the lateral enclosure walls.

The rail must engage into the receptacle

on the bottom of the housing. Care has to

be taken that the PE rail has such a position

that a proper conductor connection is

ensured.

In the case of building up the electrical

equipment in the "protective insulation" version,

appropriate sticker GHG 905 1002 P0005 can

be requested by the manufacturer.

If the inserted terminal rail is not equipped

completely with line-up terminals, the terminal

rail must be included in the equipotential earth

connection also.

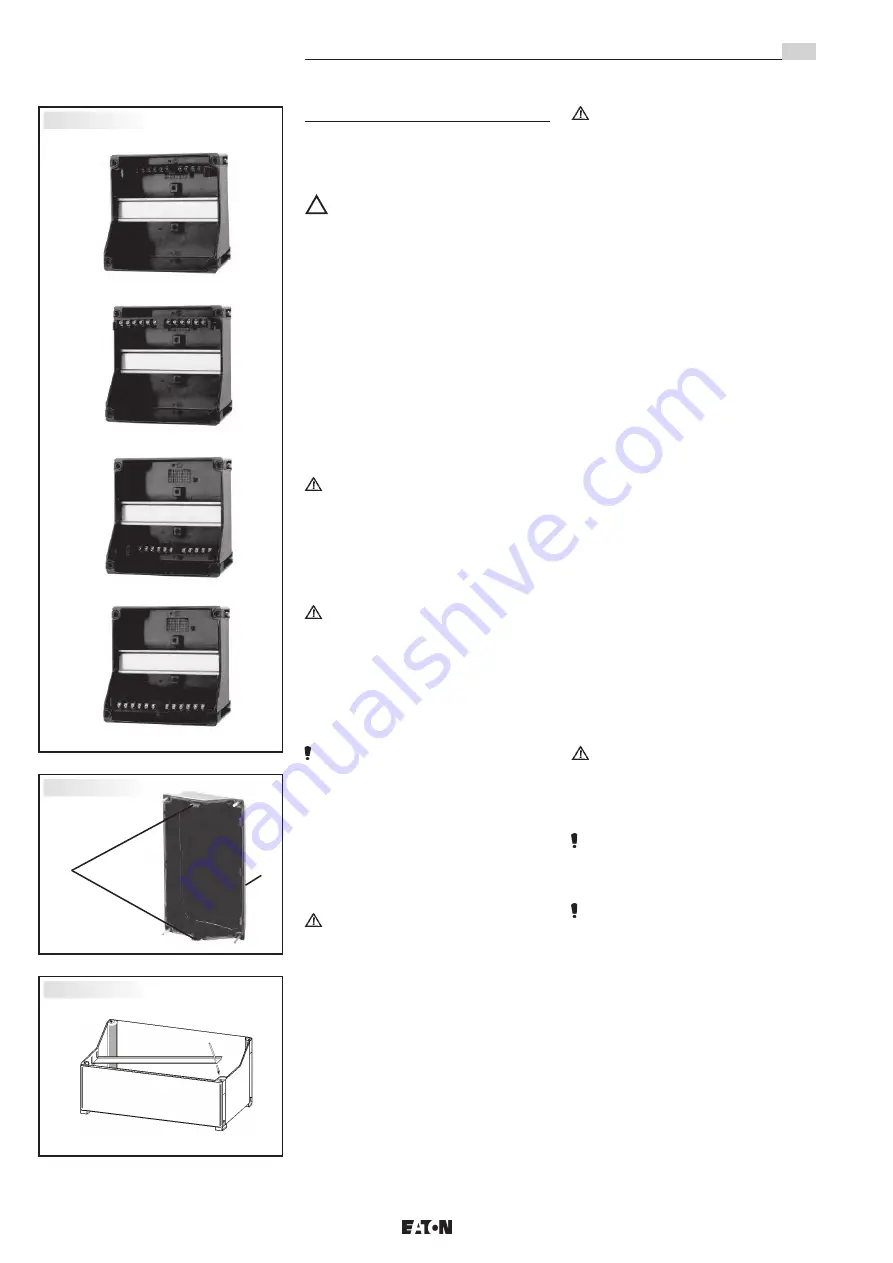

Fig. 1

Fig. 2

Fig. 3

A

B

C

D

1

2

Explosion protected terminal boxes type, GHG 72.

GB