11

6.3 Cable entries (KLE)/

Blanking plugs

Generally, only certified cable entries

and blanking plugs may be used. Flexible

cables are to be used with trumpet-shaped

cable glands or other suitable entries with

additional pull-relief.

Intrinsically safe circuits (Ex-i) are to be

connected through the coloured (light blue)

cable entries.

The mounting directives applicable to the

fitted cable entries are to be observed.

When using cable entries with a lower IP

protection than that which applies to the

device (see technical data) the IP protection

of the whole device will be reduced.

In order to establish the minimum protection

category, unused holes have to be closed with

a certified blanking plug.

Care has to be taken that when fitting the cable

entries, sealing inserts appropriate to the cable

diameter are used.

In case of sealing inserts that are cut out, it will

have to be ensured that the insert is properly

adapted to the cable diameter.

All vacant metric CCH/EATON cable entries are

to be closed with the certified blanking plug for

metric cable entries.

In order to ensure the required minimum

protection category, the cable glands shall

be tightened down.

Overtightening might impair the

protection category.

Attention: When tightening the cap

nut of the type ADE 1F metal cable entry, the

screwing is to be protected against

twisting by means of a suitable tool.

6.4 Flange and metal plates

If flange plates have to be removed in case of

plastic terminal boxes (e.g. for drilling entry

holes), attention will have to be paid to the

proper fit of the flange plate and of the clamp

clip when mounting them in order to maintain

the minimum protection category.

Flange plates for stainless steel terminal

boxes shall be fitted so that the IP protection

in maintained. Pay attention to the proper

seat of the sealing element.

PE conductors fed from outside are to be

connected to the PE terminal provided on

the flange. The maximum cross-section is

50mm².

Attention: Metal flanges, metal plates

and metal cable glands shall be included in

the equip potential earth connection.

If terminal boxes with plastic flanges are

used within the scope of the type examina-

tion certificate in ambient temperatures

below -40°C, they shall be installed in such a

way that they are protected against

inadmissible mechanical loads.

6.5 Closing the device/

cover closure

Any foreign matter is to be removed

from the apparatus.

In order to ensure the required minimum

protection category, the cover screws are to

be tightened down.

Overtightening might impair the

protection category.

6.6 Taking into operation

Prior to taking the apparatus into operation,

the tests specified in the relevant national

regulations will have to be carried out. Apart

from that, the correct functioning and installa-

tion of the apparatus in accordance with these

operating instructions and other applicable

regulations will have to be checked.

Incorrect installation and use of

the terminal boxes can invalidate the

guarantee.

7

Maintenance / Servicing

The relevant national regulations which

apply to the maintenance/repair of electrical

apparatus in explosive atmospheres, will

have to be observed (IEC/EN 60079-17).

Before opening the enclosure make sure

that the terminal box is disconnected from

the voltage, or take the appropriate

protective measures.

In case of intrinsically safe circuits, working is

permitted while voltage applies.

The required maintenance intervals depend

on the specific application and will therefore

have to be determined by the user dependent

on the conditions of use.

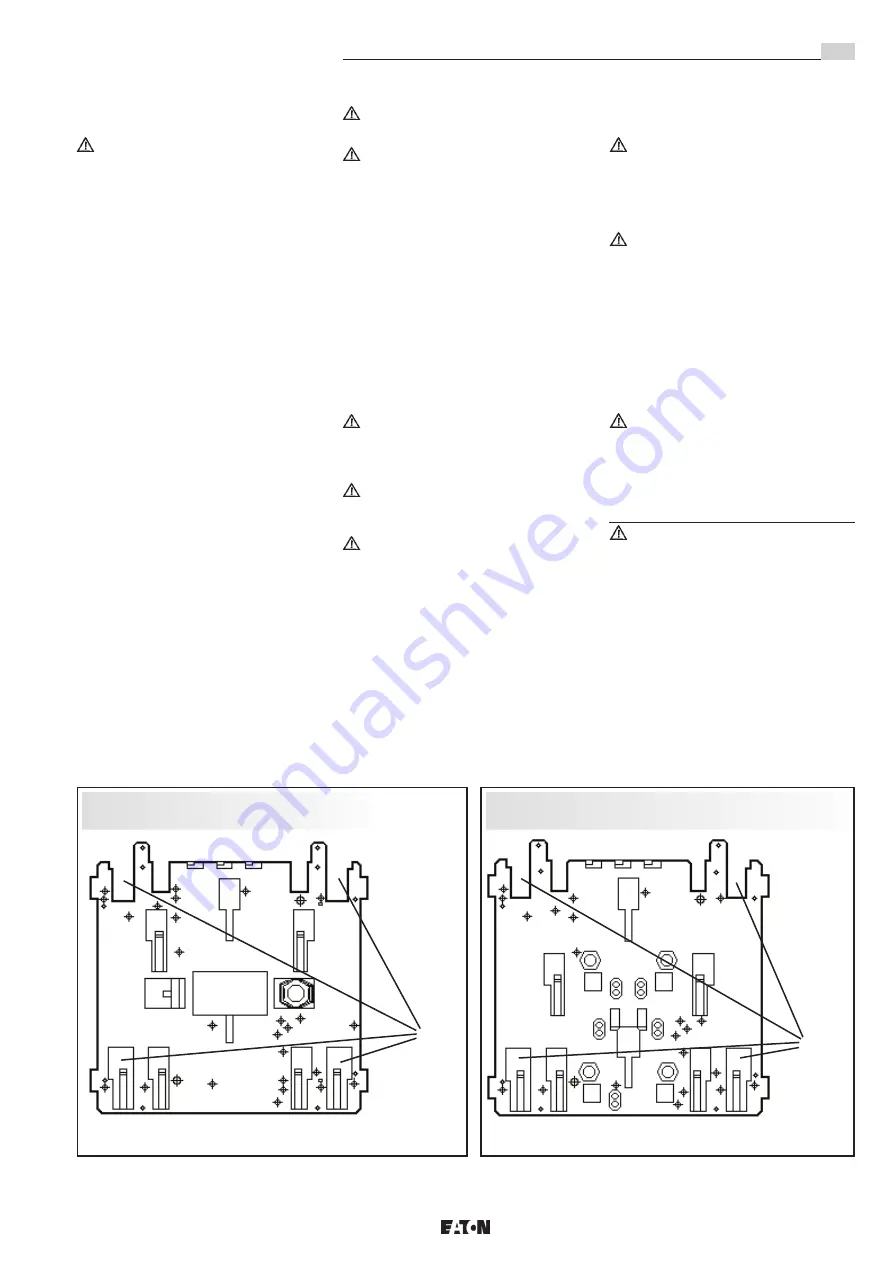

Fig. 4

Apparatus holder size 2A for pipe mounting

Fig. 5

Apparatus holder size 2A for channel- and wall mounting

C

C

Clamp fastening holes for

termional box GHG 721 0...

Clamp fastening holes for

terminal box GHG 721 0...

Explosion protected terminal boxes type, GHG 72.

GB