MAINTENANCE GENERAL

1. Perform visual, electrical and mechanical inspections on a regular basis.

The environment and frequency of use should determine this. However, it

is recommended that checks be made at least once a year. We recom-

mend an Electrical Preventive Maintenance Program as described in the

National Fire Protection Association Bulletin NFPA No. 70B: Recommend-

ed Practice For Electrical Equipment Maintenance (www. nfpa.org).

2. The lens should be cleaned periodically to ensure continued lighting

performance. To clean, wipe the lens with a clean, damp cloth. If this is

not sufficient, use a mild soap or a liquid cleaner such as Collinite NCF or

Duco #7. Do not use an abrasive, strong alkaline, or acid cleaner. Damage

may result.

3. Visually check for undue heating evidenced by discoloration of wires or

other components, damaged parts or leakage evidenced by water or

corrosion in the interior. Replace all worn, damaged or malfunctioning

components, and clean gasket seals before putting the luminaire back into

service.

4. Electrically check to make sure that all connections are clean and tight.

Mechanically check that all parts are properly assembled.

5. Check and re-torque all mounting hardware.

6. To prevent heat build-up, remove dust from the LED housing using a soft

brush or air pressure.

REPLACEMENT PARTS

Eaton’s Crouse-Hinds series linear LED luminaires are designed to provide

years of reliable lighting performance. However, should the need for replace-

ment parts arise, they are available through your authorized Eaton’s Crouse-

Hinds distributor. Assistance may also be obtained through your local Eaton’s

Crouse- Hinds representative or the Eaton’s Crouse-Hinds Sales Service De-

partment, 1201 Wolf Street, Syracuse, New York 13208, Phone 866-764-5454.

All statements, technical information and recommendations contained herein are based on information and tests we believe to be reliable. The accuracy or completeness thereof are not

guaranteed. In accordance with Eaton’s Crouse-Hinds Division’s “Terms and Conditions of Sale,” and since conditions of use are outside our control, the purchaser should determine

the suitability of the product for his intended use and assumes all risk and liability whatsoever in connection therewith.

Eaton’s Crouse-Hinds Division

IF 1897

1201 Wolf Street Syracuse, NY 13208 • U.S.A.

Revision 1

Copyright© 2019

New 10/19

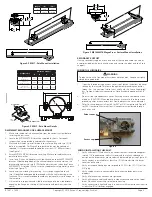

IMPORTANT INSTRUCTIONS FOR RAV1 (COMBO) LUMINAIRES

1. RAV1 luminaire shall be installed in a manner that only one color is lit at a

given time. Red and Amber colors are in two separate circuits where one

of them can be turned ON/OFF independent of another at a given time.

2. In the field installation a suitable control device shall be used to ensure

that only one circuit can be energized at any given time. This can be ac-

complished using devices such as single pole double/triple throw switch,

two circuit two/three position selector switch, etc. Switch used will have

ONE line IN and TWO lines OUT, power output from switch will go to

either of the colors (Red or Amber).

3. If the control switch is installed in the hazardous (classified) area, the

switch must be rated for the area classification.

4. The switch shall be suitable for 120-277 VAC and ‘0.5A x Number of lumi-

naires connected to the switch, hence switch is intended to control 1 or

more luminaires. Figure 10 is an example of switch controlling 1 luminaire

with 2 circuits and Figure 11 is an example of switch controlling multiple

luminaires with 1 switch.

5. The switch is installed using acceptable wiring method for the areas

involved in accordance with NEC. Please also refer installation instructions

provided by switch manufacturer prior to installation.

6. The control switch is not provided by Crouse-Hinds as a part of luminaire

or as an accessory.

Figure 11. Wiring diagram for more than one RAV1 Luminaires