I.B. 48003

Page 10

Effective 11/97

CONTACTOR HANDLING (Cont.)

7.

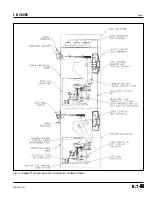

Loosen the hex-head bolt attaching the clevis at the

end of the isolating switch interlock rod to the

contactor mechanical interlock sufficiently far to free

the clevis and rod. See Figures 7 and 8. Access to

this bolt is from the low-voltage compartment. Where

two contactors are bolted together by the factory and

mechanically interlocked, (e.g., reversing or reduced

voltage) the two are removed as a single package.

The mechanical interlock and bus bar connections

between them need not be removed. However,

where three contactors are behind a single door and

mechanically interlocked, (e.g., for a single-winding

two-speed motor) the two mechanical interlocks

between the top and center contactors must also be

disconnected to withdraw any contactor. Loosen the

clevis bolts on each interlock arm of the top and

center contactors sufficiently far to free the two

interlock rods between them before attempting to

withdraw a contactor. Remove the interlock rods, but

mark them “front” and “rear” to insure correct reinstal-

lation. DO NOT DISTURB ANY FACTORY-SET

INTERLOCK ADJUSTMENTS.

8.

Use a 0.50-inch socket wrench to remove the two

horizontally-mounted positioning bolts located at the

bottom front edge of the contactor sidesheets.

9.

Carefully slide the contactor out to a balanced

drawout position or onto the fork truck or platform. All

routine inspection and maintenance can be done with

the contactor in the drawout position. Lift off the

phase barriers for easier access.

To reinstall, reverse the procedure.

INSTALLATION

This industrial type control is designed to be installed by

adequately trained and qualified personnel with appropri-

ate supervision. These instructions do not cover all

details, variations, or combinations of the equipment, its

storage, delivery, installation, check-out, safe operation,

or maintenance. Care must be exercised to comply with

local, state, and national regulations, as well as safety

practices, for this class of equipment. See START-UP

PRECAUTIONS.

For site preparation and general information regarding

receiving, storage, and installation see I.B. 48001.

CAUTION

TALL STRUCTURE — MAY TIP OVER IF MISHANDLED.

MAY CAUSE BODILY INJURY OR EQUIPMENT DAMAGE.

DO NOT REMOVE FROM SKID UNTIL READY TO

SECURE IN PLACE. READ THE HANDLING

INSTRUCTIONS IN I.B. 48001 BEFORE MOVING.

Medium-voltage motor controllers are extremely heavy

and the moving equipment used in handling must be

capable of handling the weight of the motor controller.

Confirm this capability prior to starting any handling

operations with the controller.

The motor controller should be kept in an upright position

unless specific instructions to the contrary are provided

with the controller.

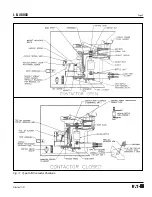

After a level installation site has been prepared, the

Ampgard

®

assemblies positioned and fastened in place,

and protective packaging removed, the individual control-

lers can be disassembled to permit access to conduit

and complete wiring. Step-by-step disassembly proce-

dures are shown on Pages 12, 13, and 14. Following the

recommended procedures will save time. All cable

connections can be made by access through the front of

the enclosure.

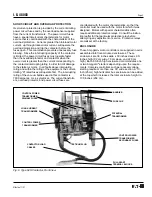

Fig. 12 Type SJS Contactor Side View