I.B. 48003

Page 15

Effective 11/97

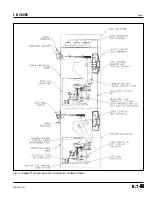

For Contactor. Be sure that:

1.

THE FOUR PHASE BARRIERS ARE INSTALLED

WHEN PROVIDED.

2.

The contactor coil is electrically isolated, to prevent

feedback into a control power transformer and a

hazardous situation.

3.

There has been a check, using an extension cord

and a separate source of AC control circuit power, of

the control circuit functions.

Operate the appropriate pushbuttons to close and open

the contactor. If the contactor does not close fully or

does not drop out fully, refer to the CONTACTOR MAIN-

TENANCE section below.

While the contactor is closed, observe the overtravel gap

between the pivot plates on the cross bar and the underside

of the lower bottle nut on each pole. This overtravel gap

should be no less than .075 inch (1.91 mm) when the

contactor is new. If less, refer to Contact Wear Allowance.

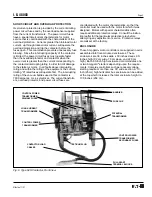

While the contactor is open, push the armature rearward

with a long screwdriver or other rod applied to the lower

end of the armature above the coil terminals. The

armature should not move because it should be firmly

against the glass polyester main frame. See Figure 11.

To correct a problem, see Changing Operating Coil

under CONTACTOR MAINTENANCE.

Disconnect the extension cord and restore the plug into

its socket on the contactor chassis.

CHECK-OUT, VACUUM INTERRUPTERS

The dielectric strength of the interrupters should be

checked before the contactor is energized for the

first time and regularly thereafter to detect at the earliest

possible date any deterioration in the dielectric strength

of the contact gap since this may result in an interruption

failure. Although an AC dielectric test is recommended, a

DC test may be performed if only a DC test unit is

available. A good vacuum interrupter will withstand a

16kV-60-Hz test or a 23kV-DC test across a .156-inch

(4-mm) contact gap. This is the nominal contact gap for a

new contactor. When performing DC tests, the voltage

should be raised to test value in discrete steps and held

for a period of one minute. When tested with an AC high

potential tester, expect a capacitance leakage current of

approximately 1.3 milliamperes. For a DC tester expect

5 microamperes. Any spark across the contact gap

indicates failure.

SOME DC HIGH POTENTIAL UNITS, OPERATING AS

UNFILTERED HALF-WAVE RECTIFIERS, ARE NOT

SUITABLE FOR TESTING VACUUM INTERRUPTERS,

BECAUSE THE PEAK VOLTAGE APPEARING

ACROSS THE INTERRUPTERS CAN BE

SUBSTANTIALLY GREATER THAN THE VALUE

INDICATED.

When a vacuum bottle is tested with voltage over 5000

volts across its open gap, there is some possibility of

generating X-rays. Test time should be minimized, and

personnel should not be closer than 10 feet (3 meters)

and preferably located behind some barrier. This is a

precaution until such time as the possible hazard is better

understood and standards are published.

Periodic dielectric tests across open contacts should not

be omitted on the basis of satisfactory contactor perfor-

mance since under certain operating conditions, the

contactor may perform satisfactorily even though one

vacuum interrupter has become defective.

The interval between periodic tests depends on the

number of operations per day, environmental factors, and

experience. It is a matter of operator judgment.

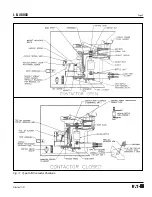

CHECK-OUT, MECHANICAL

One of the features of Ampgard

®

motor control is the inter-

locking of the contactor and isolating switch which prevents

opening the isolating switch when the contactor is closed,

and prevents closing the isolating switch if the contactor is

already closed due to some malfunction. Neither closing nor

opening of the isolating switch under load is permissable.

The isolating switch interlock arm does not move, except

when the isolating switch is being opened or closed.

Similarly, during the opening or closing of the isolating

switch, the interlock rod on the isolating switch drives the

interlock arm of the SJS contactor clockwise so that the

heavy end moves down to keep the contactor from

closing. If the isolating switch interlock rod is not attached

to the interlock arm of the contactor by the clevis shown in

Figures 7 and 8, the natural weight of the interlock arm

moves the arm to a position which prevents the contactor

from closing.

All these interlocks are intended to protect against mal-

function. But they should be tested with main POWER

OFF prior to start-up (and at intervals thereafter) by

simulating improper operation and sequencing of the

contactor and isolating switch. Failure to interlock must be

corrected before power is applied.

CAUTION