I.B. 48003

Page 16

Effective 11/97

OPERATE THE ISOLATING SWITCH ONLY WITH ALL

DOORS CLOSED AND COMPLETELY LATCHED. THE

ISOLATING SWITCH MAY FAIL TO INTERRUPT IF ITS

RATING HAS BEEN EXCEEDED BY AN

UNDETECTED INTERNAL FAULT.

GENERAL MAINTENANCE

Ampgard

®

motor controllers should be operated and

maintained by authorized and qualified personnel only.

Personnel authorized to operate the isolation switch and

those authorized to inspect, adjust, or replace equipment

inside the enclosure should have a complete understand-

ing of the operation of the controller, and must have

thorough training in the safety precautions to be followed

when working with medium-voltage equipment.

MAINTENANCE PRECAUTIONS

There is a hazard of electric shock whenever working on

or near electrical equipment. Turn off all power supplying

the equipment before starting work. Lock out the discon-

necting means in accordance with NFPA 70E, “Electrical

Safety Requirements for Employee Safety In the Work-

place.” Where it is not feasible to de-energize the sys-

tem, take the following precautions:

a) Instruct persons working near exposed parts that are

or may be energized to use practices (including

appropriate apparel, equipment and tools) in accor-

dance with NFPA 70E.

b) Require persons working on exposed parts that are

or may be energized to be qualified persons who

have been trained to work on energized circuits.

For the purpose of these instructions, a qualified person

is one who is familiar with the installation, construction, or

operation of the equipment and the hazards involved. In

addition, this person should have the following qualifica-

tions:

a) Be trained and authorized to energize, de-energize,

clear, ground, and tag circuits and equipment in

accordance with established safety practices.

b) Be trained in the proper care and use of protective

equipment, such as rubber gloves, hard hat, safety

glasses or face shields, flash clothing, etc., in accor-

dance with established practices.

c)

Be trained in rendering first aid.

d) Be knowledgeable with respect to electrical installa-

tion codes and standards, for example, the National

Electrical Code (NEC).

MAINTENANCE PROGRAM

A maintenance program should be established as soon

as the controller has been installed and put into opera-

tion. After the controller has been inspected a number of

times at monthly intervals and the conditions noted, the

frequency of inspection can be increased or decreased to

suit the conditions found.

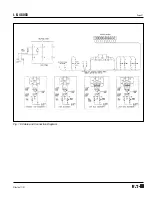

Before attempting maintenance, consult the specific

circuit diagrams supplied with the controller.

Insulation Level

After installation, and before energizing the controller for

the first time, the insulation resistance between poles,

and from each pole to ground should be measured and

recorded. It is not practical to specify an absolute value

for this reading since it is dependent on other connected

apparatus and conditions of service. However, any

unusually low reading or abrupt reduction in a reading

would indicate a possible source of trouble, and the

cause should be investigated and corrected.

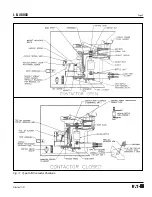

Fuses

Inspect the current-limiting fuses after each fault-clearing

operation, since this is the most severe service to which

they will be subjected. Check the fuse resistance, and

compare this value with a new fuse. A visual sign of an

open fuse is provided by a colored indicator in the top of

the fuse. This indicator pops up and is visible when the

fuse is blown.

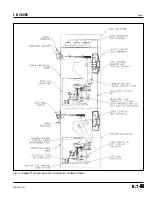

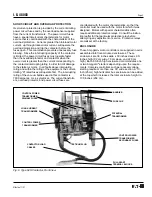

Use the fuse puller to remove and replace blown fuses.

The fuse puller is stored alongside the contactor rail. The

correct procedure for replacing fuses is described on the

operating instruction panel which is permanently fastened

inside the door to the medium-voltage compartment.

This instruction panel also lists the correct fuse rating

and fuse part number for that particular starter. The

same type, rating and part number of power circuit fuses

must be used for replacement in all cases. If preferred,

fuses may be removed and replaced by hand.

If for any reason, there is doubt about the condition of a

fuse, a simple test is to check its electrical continuity and

resistance.

DANGER