I.B. 48003

Page 20

Effective 11/97

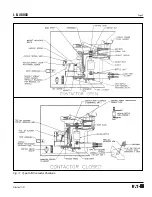

OPERATING ARM

BOTTLE WRENCH

AUXILIARY

CONTACT

CONTACTOR MAINTENANCE (Continued)

Auxiliary Contact Adjustment

The 0.410 + .010-inch (10.4 + .25-mm) gap shown for the

normally-closed Type L63 auxiliary contact in the insert

picture in the lower portion of Figure 12 is factory set. The

0.410-inch (10.4-mm) gap is important and must be held.

If the gap is too large, the hold-in winding of the operating

coil will not be inserted as the contactor closes, causing

the pick-up winding in the coil to burn out. The pick-up

winding is intermittent-duty rated. If the 0.410-inch (10.4-

mm) gap is too small, the hold winding will be inserted too

soon, reducing the pull force before the contactor is

closed, producing an oscillation of the armature similar to

an old doorbell.

The Type L64 auxiliary contact adjustment is not as

critical. In the open-contactor position, the L64 plunger

should rest lightly against the operating arm. Neither the

L63 or L64 assemblies should bottom solidly in the

closed contactor position, as discussed under Magnet

Operating Range.

A bottle wrench and a .020-inch (.51-mm) feeler gauge

are screw mounted to the right-hand sidesheet of the

contactor when the Amgpard

®

controller is shipped.

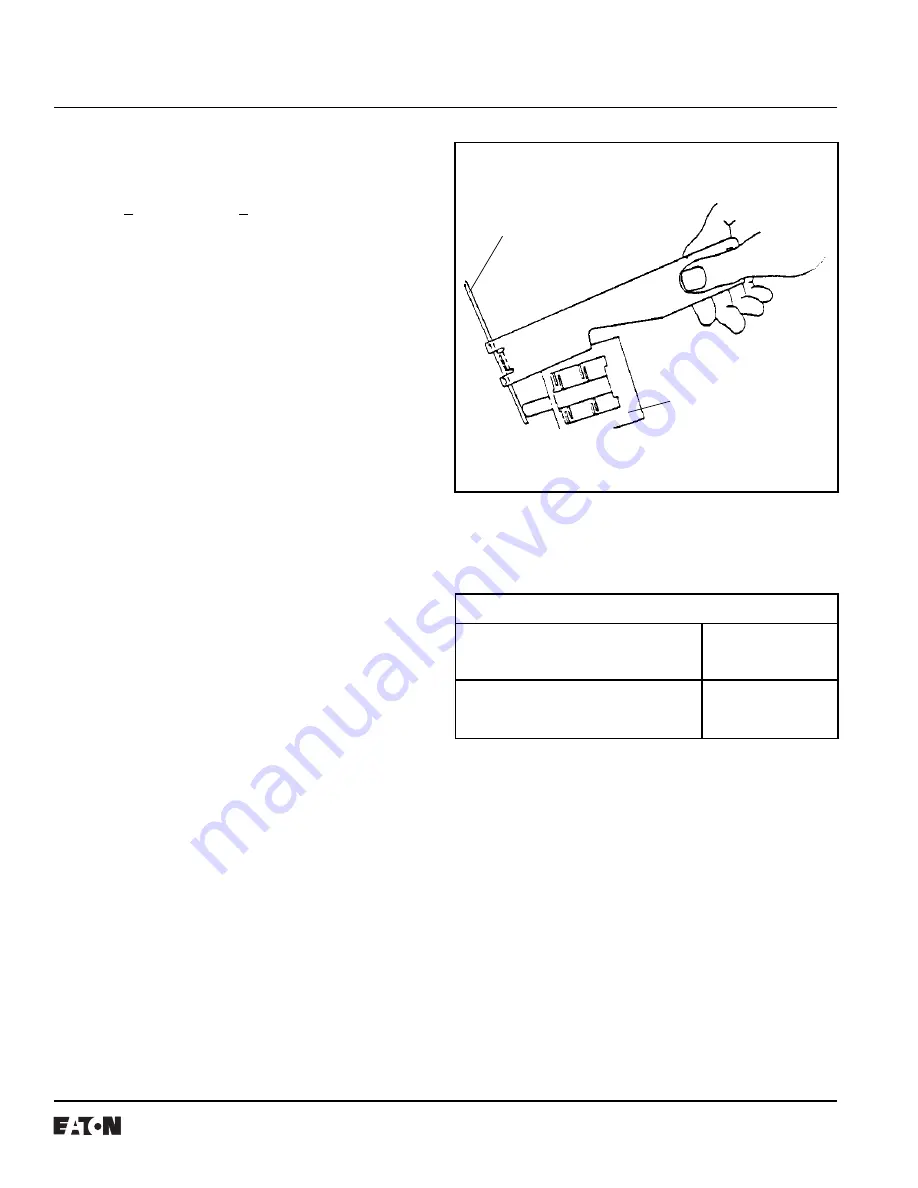

After an L64 auxiliary contact is added or replaced,

adjustment can be made by bending the operating arm

with the forked end of the bottle wrench. See Figure 15.

After an L63 auxiliary contact is replaced, gap adjustment

may be made by first loosening the jam nut on the

operating arm with a 0.438-inch open-end wrench. The

gap size is changed by rotating the 0.25"-20 bolt. Clock-

wise rotation will increase the gap distance. Counter-

clockwise rotation will decrease the gap distance. Use a

Vernier calipers or a 0.410-inch (10.4-mm) feeler gauge

to measure the gap size. After the gap has been set,

tighten the jam nut against the interlock operating arm. A

heavy-duty contactor closing tool which can be used as a

manual operator is available. Order Part No.

2147A47G17.

Vacuum Bottle Subassembly Replacement

If it becomes necessary to replace vacuum bottles,

obtain Vacuum Bottle Subassembly Replacement Kit part

number 2147A47G13, and follow the enclosed instruc-

tions. This kit includes three bottle subassemblies, as all

bottle subassemblies must be replaced at the same time.

TABLE V - RENEWAL PARTS

Replacement

Item

Kit No.

Vacuum Bottle (3) Subassemblies

2147A47G13

Feeler Gauge and Bottle Wrench

2147A47G15

Fig. 15 Adjustment of Type L64 Operator

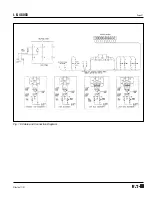

CONNECTION DIAGRAM

Figure 17 shows the routing of the conductors and

connection points to the internal portion of the SJS

control circuit. The conductor cable pattern shown in

Figure 17 is used for both two-pole and three-pole

contactors. For interconnections with other Ampgard

®

components, see the wiring diagram furnished with the

order.

5259C37