September 2003

CA03310002E

For more information visit:

www.cutler-hammer.eaton.com

11

NEMA Contactors & Starters

IT.

Electro-Mechanical

Technical Data and Specifications

Table 6. Specifications, continued

Use Class B 75°C copper wire only (or 90°C

copper wire sized for 75°C operation per

NEC).

Consult factory for higher ratings.

The Non-reversing Starter requires the use

of all six mounting screws for the maximum

rating.

Note:

At other temperatures expressed in

°C, for either inrush or sealed, use the 20°C

value from the table in the following

Description

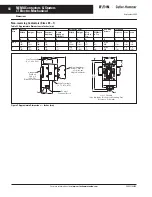

Size 00, 0

Size 1

Size 2

Size 3, 4

Size 5

Finger Protection

Front

IP20

IP20

IP20

IP20

IP20

At Terminals

IP10

IP10

IP00

IP00

IP00

At Terminals with max.

size wire installed

IP20

IP10

IP10

IP00

IP00

Terminals L1, L2, L3/T1, T2, T3

1 Wire per Terminal

(stranded or solid)

14 – 8 AWG

(1.5 – 10 mm

2

)

14 – 4 AWG

(1.5 – 16 mm

2

)

14 – 1 AWG

(1.5 – 35 mm

2

)

6 – 250 MCM

(16 – 120 mm

2

)

4 – 750 MCM

(25 – 420 mm

2

)

2 Wires per Terminal

(stranded or solid)

14 – 10 AWG

(1.5 – 4 mm

2

)

14 – 6 AWG

(1.5 – 16 mm

2

)

14 – 2 AWG

(1.5 – 25 mm

2

)

6 – 3/0 AWG

(16 – 70 mm

2

)

1/0 — 300 MCM

(50 — 150 mm

2

)

Strip Length

.45" (11 mm)

.5" (12 mm)

.7" (18 mm)

.8" (21 mm)

1.5" (40 mm)

Torque (max.)

20 lb-in (2.2 Nm)

for 14 – 10 AWG

(1.5 – 6 mm

2

);

25 lb-in (2.8 Nm) for

8 AWG (10 mm

2

)

35 lb-in (4.0 Nm)

for 14 – 10 AWG

(1.5 – 6 mm

2

);

40 lb-in (4.5 Nm) for

8 AWG (10 mm

2

);

45 lb-in (5.0 Nm) for

6 – 4 AWG

(16 mm

2

)

45 lb-in (5.0 Nm) for

Single 14 – 8 AWG

(1.5 – 10 mm

2

);

100 lb-in (11 Nm) for

Single 6 – 1 AWG

(16 – 35 mm

2

) and

Dual Wire

Combinations

250 lb-in (28 Nm)

550 lb-in (62 Nm)

Driver

2.5 mm Hex Key

3 mm Hex Key

5/32" (4 mm) Hex Key

5/16" (8 mm) Hex Key

5/16" (8 mm) Hex Key

Operation Performance

Coil Voltage (nominal)

24V DC

24V DC

24V DC

24V DC

24V DC

Coil Operating

Voltage Range (V DC)

20 – 28

20 – 28

20 – 28

20 – 28

20 – 28

Control Terminals

(- and +)

1 Wire per Terminal

14 – 12 AWG

(1.5 – 2.5 mm

2

)

14 – 12 AWG

(1.5 – 2.5 mm

2

)

14 – 12 AWG

(1.5 – 2.5 mm

2

)

14 – 12 AWG

(1.5 – 2.5 mm

2

)

14 – 12 AWG

(1.5 – 2.5 mm

2

)

(- and +)

2 Wires per Terminal

14 AWG

(1.5 mm

2

)

14 AWG

(1.5 mm

2

)

14 AWG

(1.5 mm

2

)

14 AWG

(1.5 mm

2

)

14 AWG

(1.5 mm

2

)

(P, F, R, 1, 2, 3)

1 Wire per Terminal

22 – 12 AWG

(0.5 – 2.5 mm

2

)

22 – 12 AWG

(0.5 – 2.5 mm

2

)

22 – 12 AWG

(0.5 – 2.5 mm

2

)

22 – 12 AWG

(0.5 – 2.5 mm

2

)

22 – 12 AWG

(0.5 – 2.5 mm

2

)

(P, F, R, 1, 2, 3)

2 Wires per Terminal

18 – 14 AWG

(0.75 – 1.5 mm

2

)

18 – 14 AWG

(0.75 – 1.5 mm

2

)

18 – 14 AWG

(0.75 – 1.5 mm

2

)

18 – 14 AWG

(0.75 – 1.5 mm

2

)

18 – 14 AWG

(0.75 – 1.5 mm

2

)

Torque (max.)

4.5 lb-in (.5 Nm)

4.5 lb-in (.5 Nm)

4.5 lb-in (.5 Nm)

4.5 lb-in (.5 Nm)

4.5 lb-in (.5 Nm)

Strip Length

.25 (7 mm)

.25 (7 mm)

.25 (7 mm)

.25 (7 mm)

.25 (7 mm)

Driver

.13 (3.5 mm) Flat

.13 (3.5 mm) Flat

.13 (3.5 mm) Flat

.13 (3.5 mm) Flat

.13 (3.5 mm) Flat

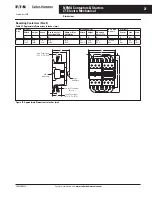

Temperature

Operating

-40° to +149°F

(-40° to +65°C)

-40° to +149°F

(-40° to +65°C)

-40° to +149°F

(-40° to +65°C)

-40° to +149°F

(-40° to +65°C)

-40° to +149°F

(-40° to +65°C)

Storage

-58° to +176°F

(-50° to +80°C)

-58° to +176°F

(-50° to +80°C)

-58° to +176°F

(-50° to +80°C)

-58° to +176°F

(-50° to +80°C)

-58° to +176°F

(-50° to +80°C)

Environmental

Shock/Vibration

15G/5G

15G/5G

15G/5G

15G/5G

15G/5G

Altitude

6600 FT (2000M)

6600 FT (2000M)

6600 FT (2000M)

6600 FT (2000M)

6600 FT (2000M)

Pull-In Time (mS) @ 24V

Excl. Debounce Time

15

15

25

30

70 – 200

Incl. Debounce Time

75

80

88

95

120 – 300

Dropout Time (mS) @ 24V

Excl. Debounce Time

5

5

12

15

50 – 150

Incl. Debounce Time

65

70

75

80

70 – 250

Watts = W

20

[1.1 – .005(T) and

Amps = A

20

[1.1 – .005(T)]

For example, inrush requirements for a NEMA

Size 2 Starter at -25°C would be:

Watts = 130 [1.1 – .005 (-25)] = 160

Amps = 5.4 [1.1 – .005 (-25)] = 6.6

Notes:

■

Response time for Control Inputs = Debounce

Time

■

The time between operating forward and

reverse must be greater than the Debounce

Time.

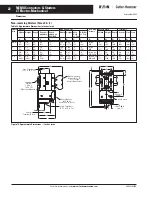

Table 7. 24V DC Power Supply Requirements @ 68°F (20°C) (see Note at left)

_ indicates missing digit/character of the Catalog Number; may have multiple values.

Contactor/Starter Size

Sealed In

Inrush

Catalog

Number

NEMA Size Wattage

Amps

Wattage

Amps

Duration

(mS)

N_11B_ _X3N

N_01B_ _ _3A

N_11C_ _X3N

00, 0

00, 0

1

3.7

3.2

4.2

.15

.13

.18

80

80

90

3.3

3.3

3.8

50

50

50

N_01C_ _ _3A

N_ _1D_ _ _3_

N_ _1E_ _ _3_

N_ _1F_ _ _3_

N_01F_ _ _3_

1

2

3, 4

5

5

3.6

5.0

5.6

12.0

13.0

.15

.21

.23

.50

.54

90

130

140

200

200

3.8

5.4

5.8

8.3

8.3

50

65

85

250

250