PUB 51079

D64RP14 SERIES A2 DIGITAL GROUND FAULT RELAY

Revision 1

May, 2005

Page 8

After the trip, if the relay operating mode is Non-Failsafe or Failsafe, the output relay will remain

tripped and the green LED will fast blink until the button is pressed (Manual Reset)

After the trip, if the relay operating mode is Pulsed Trip Auto Reset, the output relay will reset and the

green LED will revert to slow flash 3 second after the test was invoked (Auto Reset)

A “Test Record Form” is included in this instruction manual. This form provides spaces to record the

date the test was performed and the results. Those in charge of the building’s electrical installation

should retain the form in order to be available to the authority having jurisdiction.

3.

INSTALLATION INSTRUCTIONS

Place the D64RP14 in a clean dry enclosure. Try to keep the exposure to mechanical shock and

vibration to a minimum, even though the internal electronics have been encapsulated in epoxy to

improve the performance in high vibration environments.

Locate the relay close to the isolating device (circuit breaker or contactor) that is protecting the circuit

being monitored. If using an external CT keep the distance between the relay & CT as short as

possible.

Provide maximum clearance between the D64RP14 (and the external CT if being used) and any

strong magnetic flux producing devices such as power transformers, autotransformers, control

transformers, reactors, and high power conductors and buswork.

CAUTION: For reliable ground fault detection by the D64RP14 use one CT configuration only: Built-in

CT; or, External CT (i.e. do not pass power conductors through the built-in CT when using an

external CT.)

3.1

MOUNTING

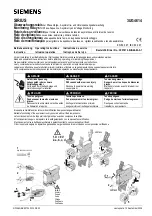

Refer to Figure 3 for mounting dimensions of the D64RP14 relay. It is designed to be mounted with

either mounting screws or 35 mm DIN rail.

Two #8-32 x 3/4" (M4 x 20) mounting screws are required for screw mounting.

For DIN rail mounting the rail should be bolted to a flat surface. Install the DIN rail horizontally. Allow at

least ¾” (20 mm) of rail to extend beyond each end of the relay. Secure the relay to the DIN rail

ensuring the white release latches at the bottom of the relay engages the rail. If the relay is to be

mounted in any other position take appropriate steps to prevent the relay from becoming disengaged

from the DIN rail.

3.2

BUILT-IN CURRENT TRANSFORMER

The D64RP14 has a built-in current transformer (CT) with 1.1” (28 mm) opening.

Refer to Figure 1. Pass the neutral conductor running from the star point of the transformer secondary

to the Neutral Grounding Resistor (NGR) through the CT window. Note that the relay is located on the

ungrounded side of the NGR. This is the preferred location so that any ground ahead of the NGR but

after the D64RP14 will be detected.

The D64RP14 Trip Level range is 1 Amp to 10.0 Amps when using the built-in CT. The maximum

continuous primary phase current is to be 100 Amps.

3.3

EXTERNAL CURRENT TRANSFORMER

Refer to the Glossary of Terms to determine if an external Current Transformer is required for the

application.