SLX9000 Adjustable Frequency Drives User Manual

MN04003020E

For more information visit:

www.eaton.com

2-3

January 2009

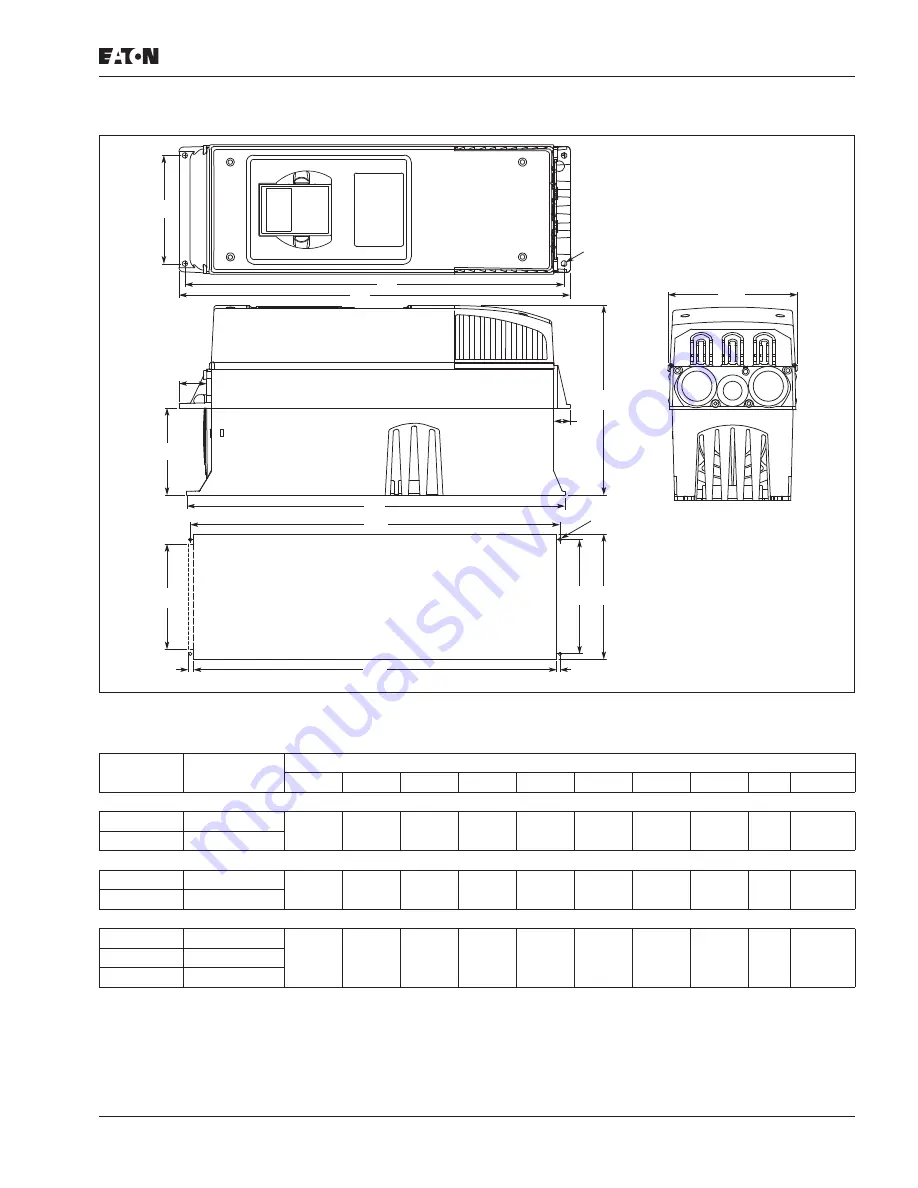

Figure 2-2: SLX9000 Dimensions, NEMA Type 1 and NEMA Type 12 with Flange Kit, MF4 – MF6

Table 2-2: Dimensions for SLX9000, MF4 – MF6 with Flange Kit

Voltage

hp (I

H

)

Approximate Dimensions in Inches (mm)

W1

W2

H1

H2

H3

H4

H5

D1

D2

Dia. A

Frame Size — MF4

230

3/4 – 3

5.0

(128)

4.5

(113)

13.3

(337)

12.8

(325)

12.9

(327)

1.2

(30)

.9

(22)

7.5

(190)

3.0

(77)

.3

(7)

480

1 – 5

Frame Size — MF5

230

5 – 7-1/2

5.6

(143)

4.7

(120)

17.0

(434)

16.5

(420)

16.5

(419)

1.4

(36)

.7

(18)

8.4

(214)

3.9

(100)

.3

(7)

480

7-1/2 – 15

Frame Size — MF6

230

10 – 15

7.7

(195)

6.7

(170)

22.0

(560)

21.6

(549)

22.0

(558)

1.2

(30)

.8

(20)

9.3

(237)

4.2

(106)

.3

(7)

480

20 – 30

575

2 – 25

W2

H1

H2

D2

Flange Opening

H4

H5

H3

W1

Dia. A

D1

W3

W4

W5

Dia. B

H7

H6

H9

H8

Summary of Contents for Cutler-Hammer SLX9000 Series

Page 1: ...SLX9000 Adjustable Frequency Drives User Manual Effective January 2009 Supersedes October 2008...

Page 2: ......

Page 171: ......