SPI9000 Inverter Unit FI9 – FI14 User Manual

MN04004002E

For more information visit:

www.EatonElectrical.com

5-29

September 2006

Applications (S6.8.4)

At location S6.8.4, you can find the Applications submenu containing information on the

application currently in use and all other applications loaded into the inverter. The following

information is available:

Table 5-14: Applications Information Pages

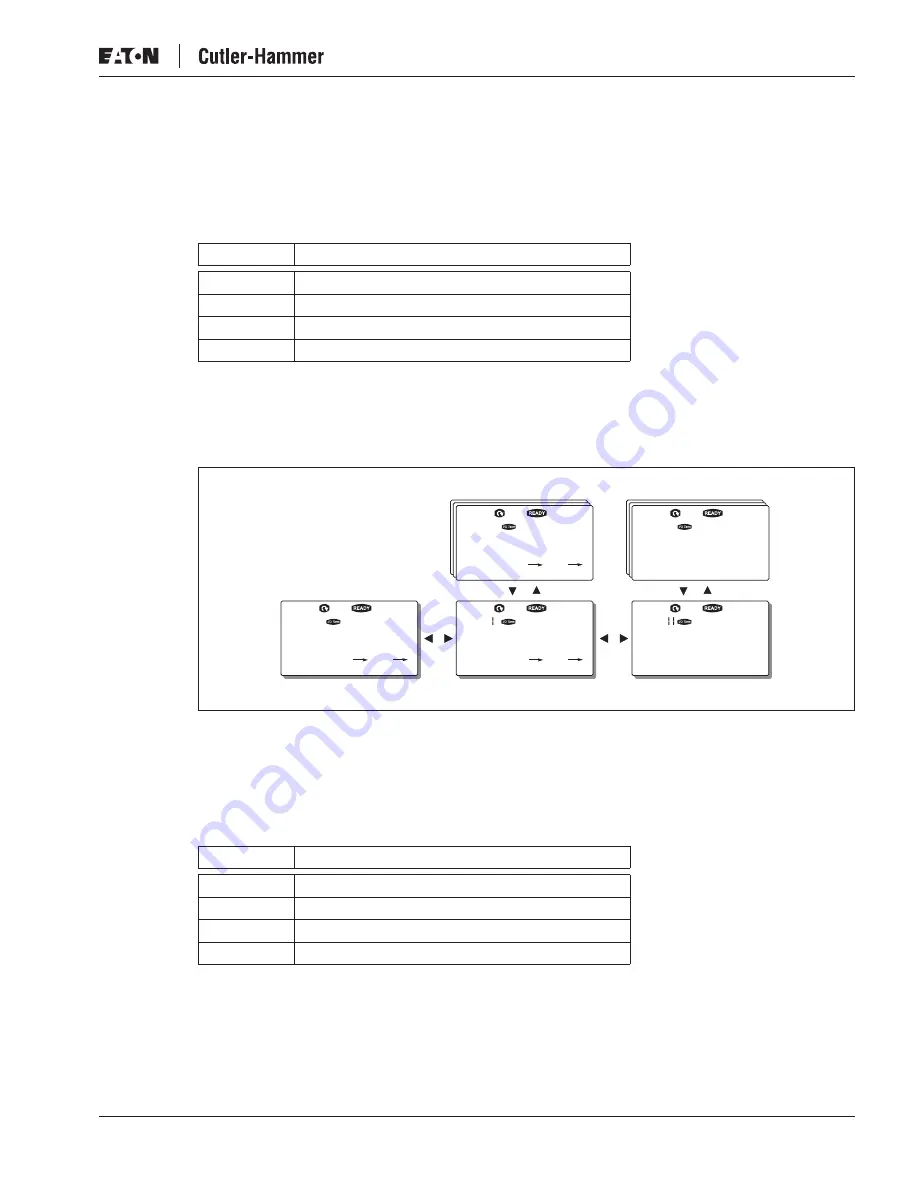

In the Applications information page, press Menu Button Right to enter the Application pages

of which there are as many as there are applications loaded into the inverter. Locate the

desired application with the Browser buttons and then enter the Information pages with

Menu Button Right. Use the Browser buttons to see the different pages.

Figure 5-27: Applications Info Submenu

Hardware (S6.8.5)

The Hardware information page provides information on the following hardware-related

topics:

Table 5-15: Hardware Information Pages

Page

Counter

6.8.4.#

Name of application

6.8.4.#.1

Application ID

6.8.4.#.2

Version

6.8.4.#.3

Firmware interface

Page

Counter

6.8.5.1

Nominal power of the unit

6.8.5.2

Nominal voltage of the unit

6.8.5.3

Brake chopper

6.8.5.4

Brake resistor

Applicatio

n

s

56.8.4

Applicatio

n

id

R6.8.4. .

A1

A7

D1

D3

Basic

R6.8.4.

FIFF01

S

ta

n

dard

D1

D3

Versio

n

2.01