14

Instruction Book

IB182942EN July 2018 www.eaton.com

DST-2-VR

+

VR-Series

+

Replacement Circuit Breaker

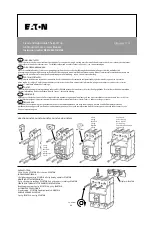

Figure 4.8.d shows the circuit breaker in the closed state after the

closing springs have been recharged. The recharging of the spring

rotates the closing cam one half turn. In this position the main link

roller rides on the cylindrical portion of the cam, and the main link

does not move out of position.

4.3.3 TRIPPING OPERATION

When the trip bar “D” shaft (Figure 4.8.b, Item 9) is turned by

movement of the shunt trip clapper (11), the trip latch will slip past

the straight cut portion of the trip bar shaft and will allow the banana

link and main link roller to lower. The energy of the opening spring

and contact loading springs is released to open the main contacts.

The mechanism is in the state illustrated (Figure 4.8.b) after the

circuit breaker is tripped open.

4.3.4 TRIP-FREE OPERATION

When the manual trip button is held depressed, any attempt to close

the circuit breaker results in the closing springs discharging without

movement of the pole shaft or vacuum interrupter stem.

4.4 CONTROL SCHEMES

There are two basic control schemes for the VR-Series

+

circuit

breaker elements, one for dc control and one for ac control voltages

(Figure 4.3). Specific customer order wiring schematics and

diagrams are included with each circuit breaker.

There may be different control voltages or more than one tripping

device, but the principal mode of operation is as follows:

As soon as the control power is applied, the spring charging motor

automatically starts charging the closing spring. When the springs

are charged, the motor cut off LS1/bb switch turns the motor off.

The circuit breaker may be closed by closing the control switch close

(CS/C) contact. Automatically upon closing of the circuit breaker, the

motor starts charging the closing springs. The circuit breaker may be

tripped any time by closing the control switch (CS/T) contacts.

Note the position switch (PS1) contact in the spring release circuit

in the scheme. This contact remains closed while the circuit breaker

is being racked between the ‘Test’ and ‘Connect’ positions for

VR-Series

+

circuit breakers. Consequently, it prevents the circuit

breaker from closing automatically, even though the control close

contact may have been closed while the circuit breaker is racked to

the ‘Connect’ position.

When the CS/C contact is closed, the SR closes the circuit breaker.

If the CS/C contact is maintained after the circuit breaker closes, the

Y relay is picked up. The Y/a contact seals in Y until CS/C is opened.

The Y/b contact opens the SR circuit, so that even though the circuit

breaker would subsequently open, it could not be reclosed before

CS/C was released and remade. This is the anti-pump function.

4.4.1 TIMING

The opening and closing times for the circuit breakers vary

depending upon the control voltage, power rating, environment and

test equipment. Differences in timing are expected between initial

factory measurements and field inspections. Circuit breaker timing

can be measured by service personnel using available equipment

before installation and in conjunction with regular maintenance

periods to assist in tracking the general health of the circuit breaker.

Typical ranges as observed using nominal control voltages are listed

in Table 4.

Tablt 4. Timt Ptr Evtnt

Event

Milliseconds

Closing Time

(From Initiation of Close Signal to Contact Make)

45 - 60

Opening Time

(Initiation of Trip Signal to Contact Break)

30 - 38

Reclosing Time

(Initiation of Trip Signal to Contact Make)

140 - 165

otte:

N

Values are typical at nominal rated control voltage(s).

4.5 SECONDARY CONNECTION BLOCK

The breaker control circuit is connected to the switchgear control

through secondary connection block (Figure 3.3.b). The contacts

engage automatically when the breaker is racked into the “test” and

“connect” positions. The socket half of the connection is located in

the cubicle and a jumper of multiconductor cable can complete the

control connections (for testing) when the breaker is withdrawn from

the cell.

4.6 INTERLOCKS

WARNING

INTERLOCKS ARE PROTECTIVE DEVICES FOR PERSONNEL AND

EQUIPMENT. DO NOT BYPASS, MODIFY, OR MAKE INOPERATIVE ANY

INTERLOCKS. DOING SO COULD CAUSE DEATH, SERIOUS PERSONAL

INJURY, AND/OR PROPERTY DAMAGE.

There are several interlocks built into the VR-Series

+

vacuum

replacement breakers. Each of these interlocks, though different in

form, duplicate or exceed in function that of the original breaker.

These interlocks exist to safeguard personnel and equipment. The

basic premise behind the interlocking arrangement on the vacuum

replacement breaker is that the breaker must not be inserted into

or removed from a live circuit while the main contacts are closed.

Also considered in the interlocking is that the breaker should pose

no greater risk than necessary to the operator in or out of the cell.

In addition to the original interlocks, VR-Series

+

breakers provide an

anti-close interlock.

4.6.1 ANTI-CLOSE INTERLOCK

The anti-close interlock prevents discharging of the closing springs if

the breaker is already closed (Figure 4.5, Item 11). When the breaker

is closed, the interlock component moves away from the spring

release clapper so that it cannot lift the spring release latch (9).

4.6.2 SHUTTER OPERATING MECHANISM

Each breaker cell is equipped with a shutter to shield the high

voltage stabs in the cubicle when the breaker is not in the cubicle.

The shutter is regulated by the shutter operating mechanism located

on the right side of the breaker. This mechanism opens the shutter

as the breaker is racked into the cell and closes the shutter as the

breaker is racked out of the cell.