86270LX

R e t

r

o f i t K i t

N o v a ( c o n t . )

technical furniture

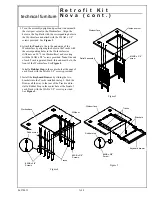

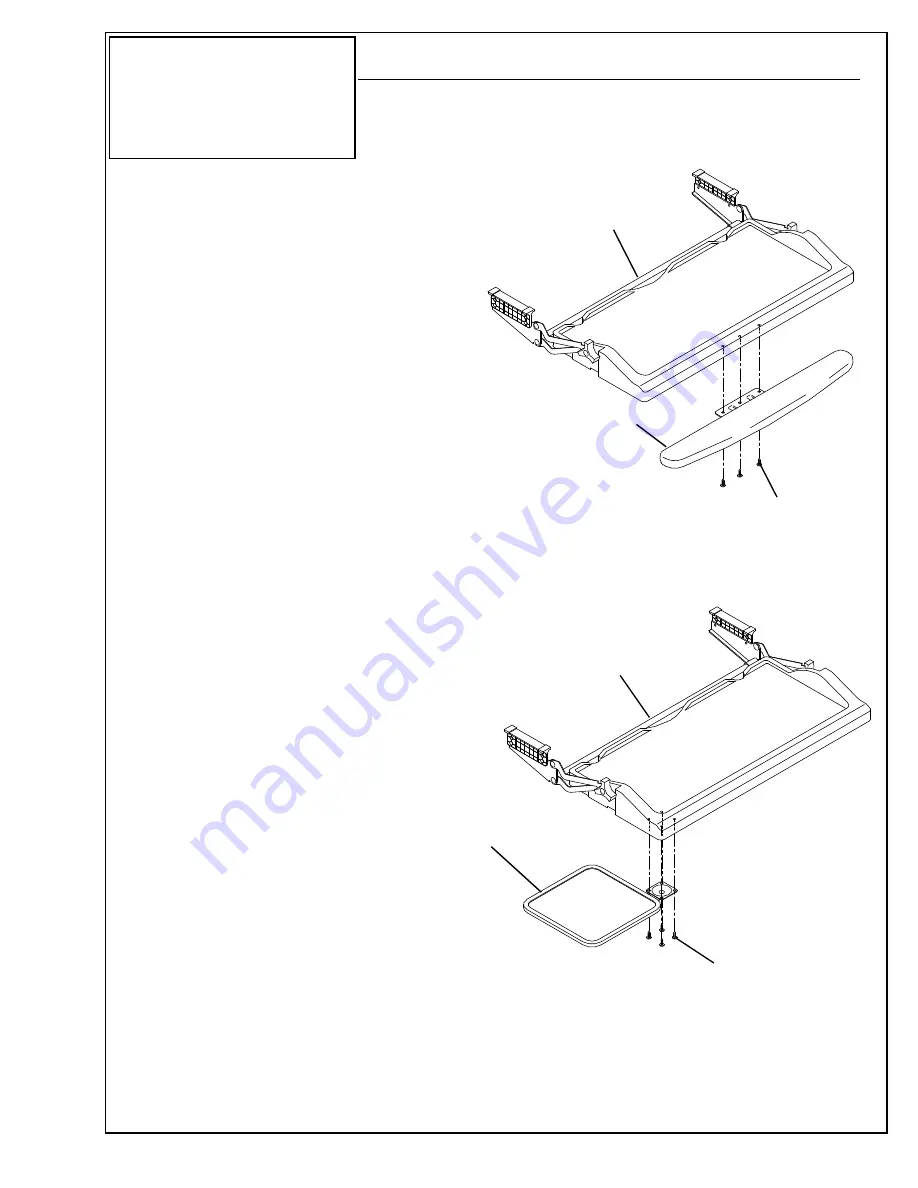

7. Attach the

Adjustable Mousing Surface

to the key-

board drawer using the pre-drilled holes and four

#10AB x 5/8” phillips head screws provided. See

Figure 7

.

NOTE

: The mousing surface can be attached to either

the right hand or the left hand side of the drawer.

6. Attach the

Palm Rest

to the front of the keyboard

drawer using the pre-drilled holes and three #8AB x

1/2” phillips head screws provided. See

Figure 6

.

Figure 6

Figure 7

Palm rest

Keyboard drawer

#8AB x 1/2” phillips

head screws

Keyboard drawer

Adjustable mousing

surface

#10AB x 5/8” phillips

head screws

A-31

Summary of Contents for LINX

Page 1: ...Modular Furniture LINX Modular Furniture Installation manual...

Page 24: ...84913 Bolt on Peninsula P e n i n s u l a B o l t o n technical furniture...

Page 41: ...R e t r o f i t K i t N o v a c o n t 86270 technical furniture A 34...

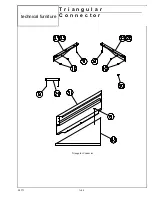

Page 51: ...84571 Triangular Connector T r i a n g u l a r C o n n e c t o r technical furniture A 44...

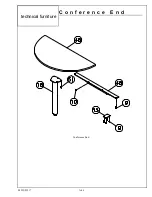

Page 53: ...84252 85217 Conference End C o n f e r e n c e E n d technical furniture A 46...

Page 56: ...81071 B C o n f e r e n c e T a b l e technical furniture A 49...

Page 57: ...84085 Posting Shelf P o s t i n g S h e l f technical furniture A 50...

Page 58: ...81046 Storage Shelf S t o r a g e S h e l f technical furniture A 51...

Page 78: ...80954LX L o c k i n g C o m p a r t m e n t s c o n t technical furniture D 11...

Page 112: ...85089 W h i t e P e g A n d B i n B o a r d s c o n t technical furniture E 12...

Page 119: ...85082 F a b r i c T e c h W a l l c o n t technical furniture E 19...

Page 122: ...85093 C o r n e r L a m i n a t e H o o k O n S h e l v e s c o n t technical furniture E 22...