Installation

M-Max Series Adjustable Frequency Drive

MN04020003E—October 2013 www.eaton.com

49

Insulation Testing

The M-Max series frequency inverters are tested, delivered

and require no additional testing.

WARNING

On the control signal and the connection terminals of the

frequency inverter, no leakage resistance tests are to be

performed with an insulation tester.

WARNING

Wait at least 5 minutes after switching the supply

voltage off before you disconnect a connection on the

connection terminals (L1, L2/N, L3, U/T1, V/T2, W/T3,

R+, R–) of the frequency inverter.

If insulation testing is required in the power circuit of the

PDS, you must consider the following measures.

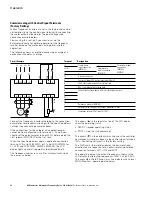

Testing the Motor Cable Insulation

Disconnect the motor cable from connection terminals U/T1,

V/T2 and W/T3 of the frequency inverter and from the motor

(U, V, W). Measure the insulation resistance of the motor

cable between the individual phase conductors and between

the phase conductor and the protective conductor.

The insulation resistance must be greater than 1M ohm.

Testing the Input Cable Insulation

Disconnect the power cable from the input supply network

and from connection terminals L1, L2/N and L3 of the

frequency inverter. Measure the insulation resistance of the

input cable between the individual phase conductors and

between each phase conductor and the protective

conductor.

The insulation resistance must be greater than 1M ohm.

Testing the Motor Insulation

Disconnect the motor cable from the motor (U, V, W) and

open the bridge circuits (star or delta) in the motor terminal

box. Measure the insulation resistance of the individual

motor windings. The measurement voltage must at least

match the rated voltage of the motor but is not to exceed

1000V.

The insulation resistance must be greater than 1M ohm.

Consider the information from the motor manufacturer in

testing the insulation resistance.