8

INM MTL 9492-PS-PLUS Rev 2

3 .5 Assembly

3 .5 .1 Fitting earth rails

a) In upper position

Before fitting insulating mounting blocks IMB57, check that the swing nuts in the base of

each unit are turned back into the moulding. Locate the mounting blocks on the DIN rail in the

chosen position and tighten the screws (see figure 3.11). Check that the swing nuts rotate

correctly to locate underneath the flanges of the DIN rail.

Slide a straight earth-rail bracket ERB57S into the upper slot in each mounting block. Push two

plastic push fasteners into each bracket to locate the brackets in the mounting blocks.

Cut earth rail ERL7 to the length needed. Slide the required number of ETM7 earth terminals

(5mm or 7mm wide) onto the rail. Clamp each end of the earth rail to earth-rail brackets ERB57S

using the terminal clamps (14mm, 35mm

2

) supplied. Fit an earth clamp (10mm, 16mm

2

) to the

free end of each earth-rail bracket.

Note: For lengths of earth-rail greater than 500mm, provide additional support by installing a

third IMB57 mounting block and earth-rail bracket, mid-way between the end mounting blocks.

Snap out the perforated extension between the lugs on this mounting block if a continuous

tagging strip is to be fitted (see figure 3.4).

b) In lower position, where at least 150mm clearance exists on one side, measured from

the edge of the mounting block.

As for a), but slide earth-rail brackets ERB57S into the lower slots in each mounting block.

c) In lower position, where there is insufficient clearance to fit earth-rail brackets ERB57S.

As for a), but slide offset earth-rail brackets ERB57O into the upper slot in each mounting

block before assembling the mounting blocks to the DIN rail. ERB57S brackets cannot be used

because they obscure the mounting blocks' fixing screws.

3 .5 .2 Fitting tagging strips

Assemble mounting blocks IMB57 to the DIN rail as above. Cut TAG57 tagging strip and label to the

length needed, and insert label so that the appropriate side is visible. Clip the strip onto the lugs on

the mounting blocks. Hinge up the strip to provide access to the tops of the power supplies.

Note: If necessary, provide additional support for long lengths of tagging strip by installing an

extra IMB57 mounting block mid-way between the end mounting blocks. Snap out the perforated

extension between the lugs on this mounting block.

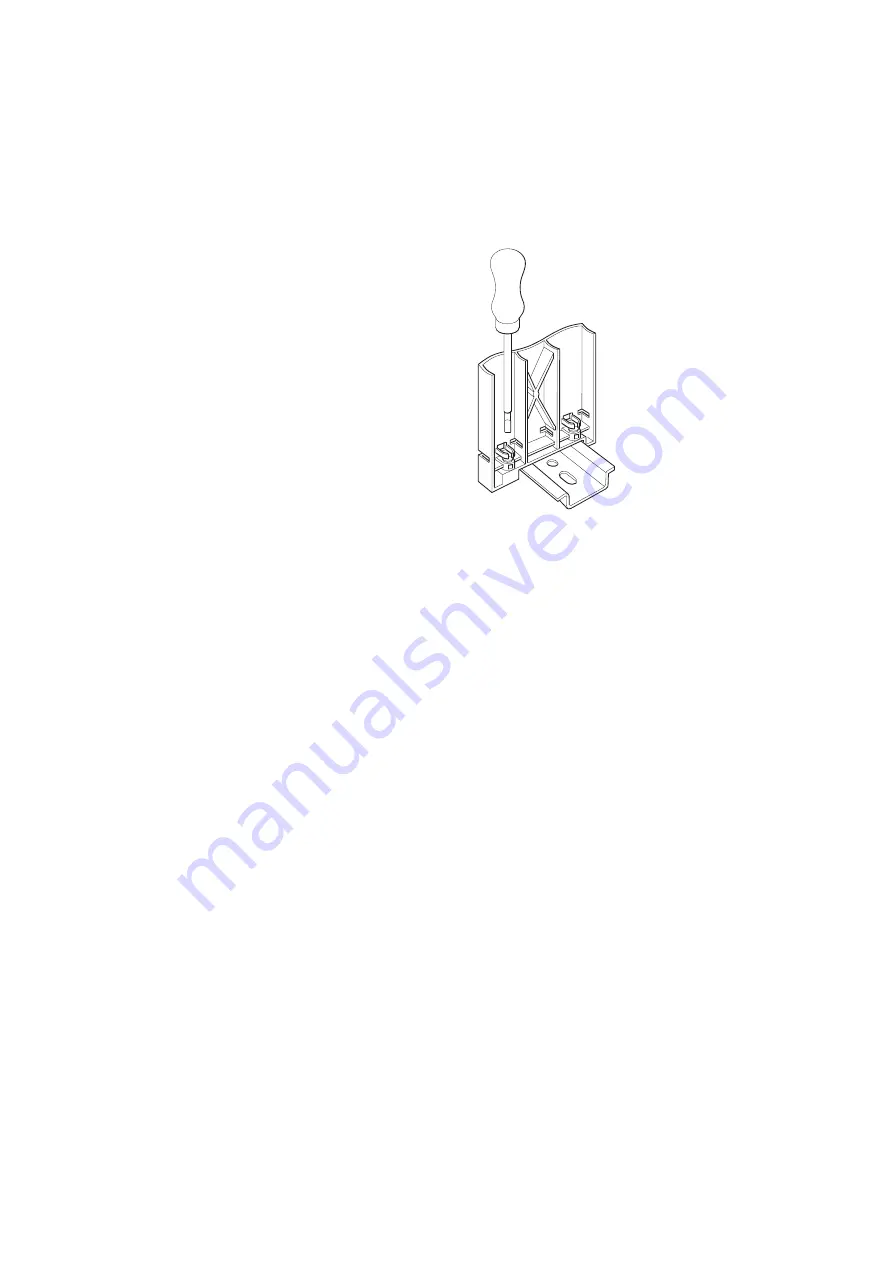

Figure 3 .11:

Fitting IMB57