18

Instructional Booklet

IB02102006E

Effective May 2011

Type MVS (previously WLI)

metal-enclosed switchgear—

4.76 kV, 15.0 kV, 27.0 kV, and 38.0 kV

eaton corporation

www.eaton.com

Override of the switch interlock safety latch

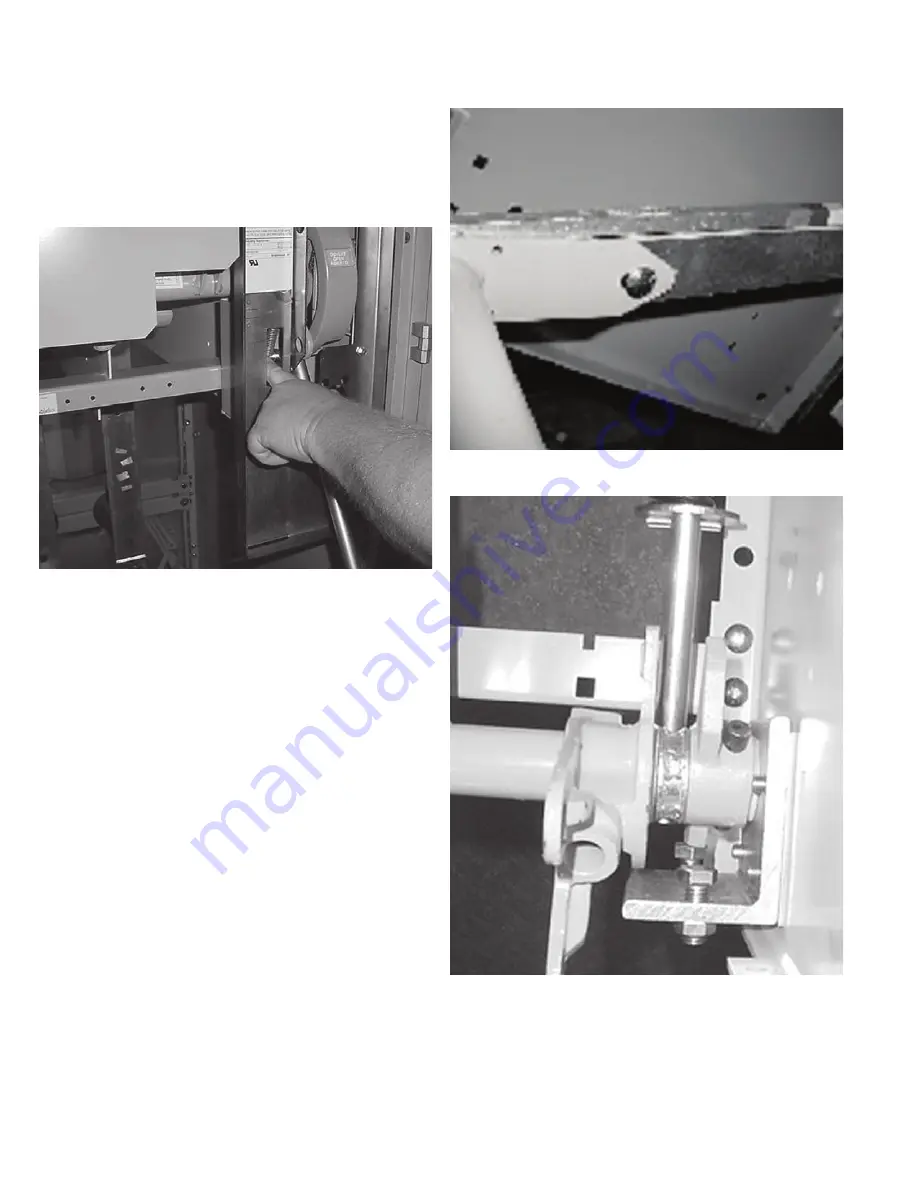

To operate the switch with the door open, the safety latch (see

Figure 23

) must be disengaged . To close the switch, insert the

handle into the handle casting and push upward, at the same time

push the latch on the left side of the safety barrier downward until

the handle casting clears the interlocking pin . Reverse this procedure

to open the switch .

Figure 23. Defeating the Door/Mechanism Interlock

Closed-Open-Stop adjustment

Step 1e:

Remove the switch mechanism cover (see

Figure 23

) by

removing the three bolts in the side sheet flange . Viewing switch

mechanism from the top, the bottom stop bolt and nut adjusts the

closed position (see

Figure 25

) . In the closed position, the shaft rod

ends should be slightly over toggle . This can be easily checked by

laying a straight edge on top of the drive rod so that its end extends

over the shaft (see

Figure 24

) . If a 0 .0625 to 0 .125 inch (1 .59 to

3 .18 mm) gap appears between the straight edge and the

drive rod, the adjustment is correct .

Figure 24. Over Toggle Check

Figure 25. Closed-Open-Stop Adjustment Bolts

otee:

N

There are two blade and break jaw configurations used on the “MVS”

(previously the WLI) switch design . The original design used a flat break jaw

with a “hook” cutout on the bottom and each blade had two indentations

(“bullets”) that bore onto the break jaw surfaces . The later design, initiated

in the year 2000, used a break jaw that has a ridge on each side and each

blade has flat contact surfaces . This instruction book will address only

the later design .