19

Instructional Booklet

IB02102006E

Effective May 2011

Type MVS (previously WLI)

metal-enclosed switchgear—

4.76 kV, 15.0 kV, 27.0 kV, and 38.0 kV

eaton corporation

www.eaton.com

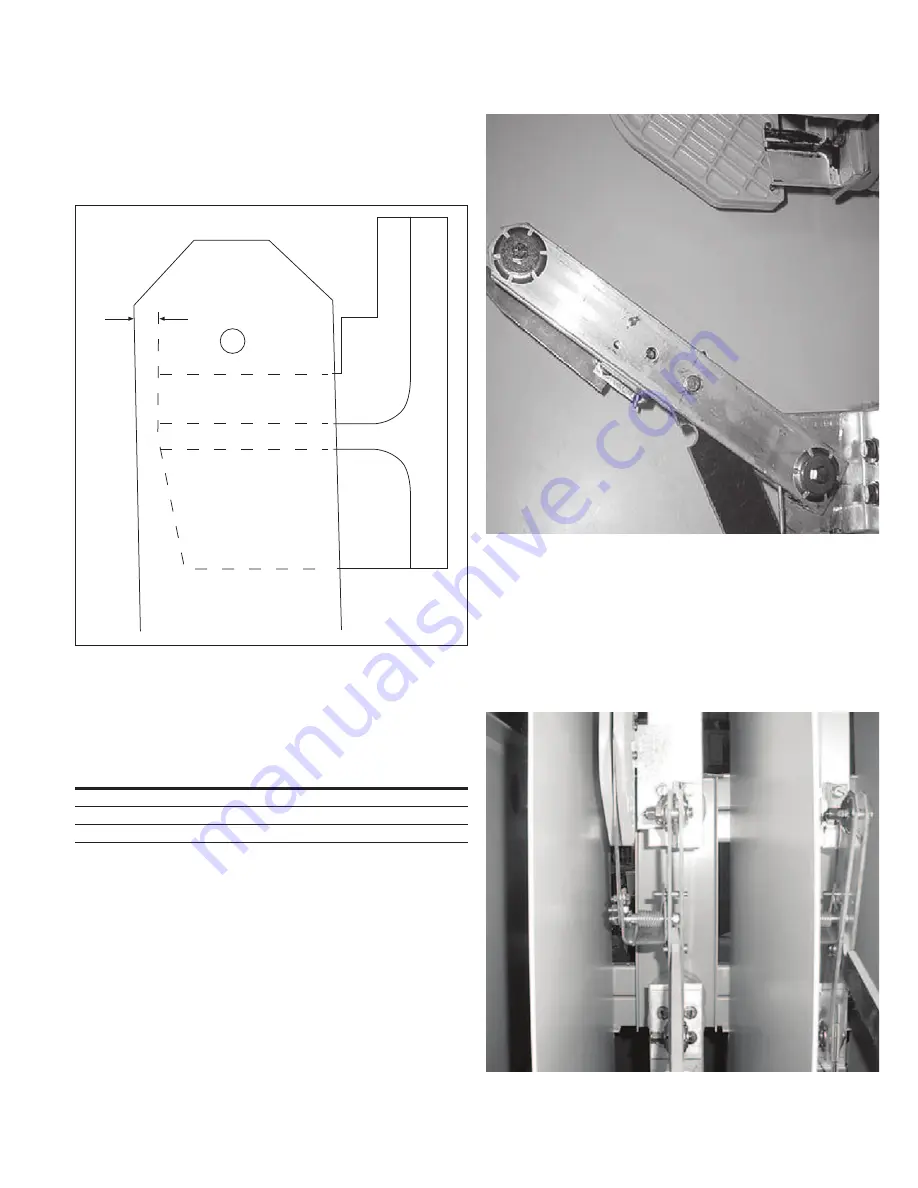

Step 2e:

Check to see that the blades are fully closing . To do this,

measure the distance from the end of the break jaw to the front

edge of the blade . This dimension should be 0 .10 to 0 .30 inches

(2 .54 to 7 .62 mm) . Should adjustment be required, loosen the

bolt holding the drive rod to the shaft and adjust the blade travel .

Re-tighten the bolt to 25 ft-lbs (33 .90 Nm) (see

Figure 27

) .

Figure 26. Break Jaw and Blade Clearances

In the “Open” position, the clearance between the edge of the

main blade and the break jaw should be as listed in

Table 4

(see

Figure 27

) . The top stop bolt adjusts this dimension .

Table 4. Main Blade to Break Jaw Clearances

open Gap Dimension

inches (mm)

kV class

6.625 ± 0.125 (168.28 ± 3.18)

4.76

6.625 ± 0.125 (168.28 ± 3.18)

15

11.00 ± 0.125 (279.40 ± 3.18)

27 or 38

0.125–0.281

Figure 27. Open Gap Distance

Step 3e:

If the switch is equipped with key interlocking, care must be

taken when replacing the switch mechanism cover to ensure that

it is properly repositioned . Elongated holes in the MVS side sheet

allow for vertical adjustment . The key interlock bolt must clear the

“Open-Closed” indicating cam casting when retracted .

Main blade alignment

For the following procedure, refer to

Figure 28

.

Figure 28. Main Blade and Flicker Blade Alignment